Seam sealing and taped seams are both techniques used in apparel to enhance water resistance and durability. Seam sealing involves applying a waterproof coating over stitched seams, preventing water from penetrating through needle holes. Taped seams, however, use adhesive tape applied over the stitching for stronger, more flexible waterproofing, commonly preferred in high-performance outdoor garments.

Table of Comparison

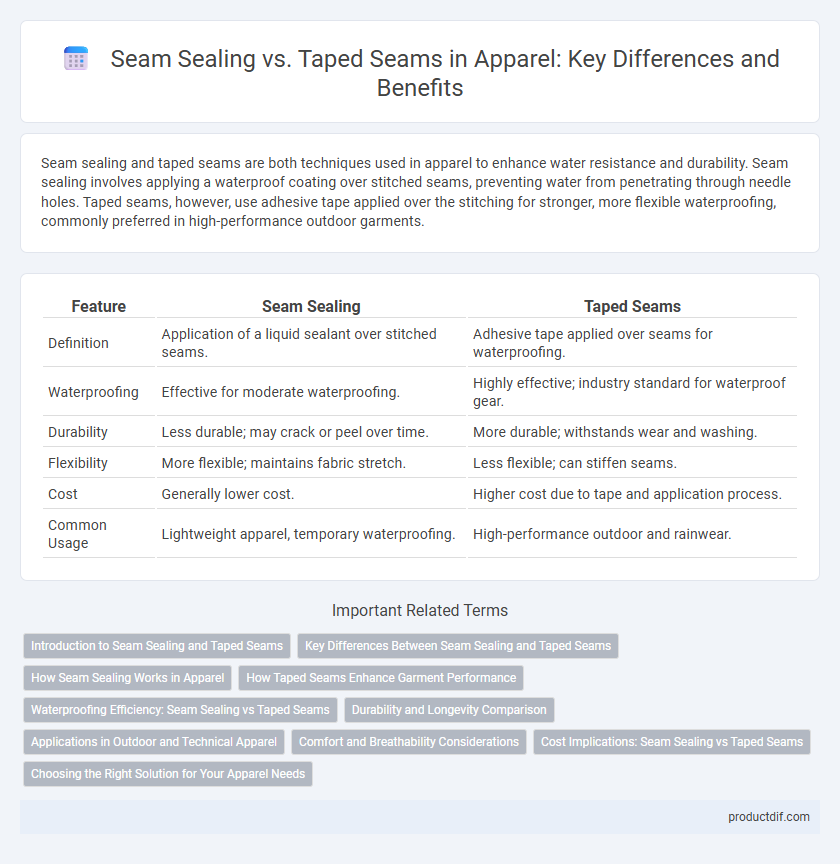

| Feature | Seam Sealing | Taped Seams |

|---|---|---|

| Definition | Application of a liquid sealant over stitched seams. | Adhesive tape applied over seams for waterproofing. |

| Waterproofing | Effective for moderate waterproofing. | Highly effective; industry standard for waterproof gear. |

| Durability | Less durable; may crack or peel over time. | More durable; withstands wear and washing. |

| Flexibility | More flexible; maintains fabric stretch. | Less flexible; can stiffen seams. |

| Cost | Generally lower cost. | Higher cost due to tape and application process. |

| Common Usage | Lightweight apparel, temporary waterproofing. | High-performance outdoor and rainwear. |

Introduction to Seam Sealing and Taped Seams

Seam sealing and taped seams are essential techniques in apparel manufacturing for enhancing garment waterproofing and durability. Seam sealing involves applying a waterproof sealant over stitched seams to prevent water penetration, while taped seams utilize adhesive tape applied along the stitching for a similar protective barrier. Both methods improve performance in outdoor and technical clothing by ensuring seams remain impermeable under various weather conditions.

Key Differences Between Seam Sealing and Taped Seams

Seam sealing involves applying a waterproof coating directly onto the fabric's seams to prevent water penetration, while taped seams use adhesive tape to cover and reinforce the stitching. Seam sealing typically provides greater flexibility and breathability, making it ideal for high-performance outdoor apparel. Taped seams, on the other hand, offer stronger durability and are preferred in heavy-duty garments where maximum waterproof protection is essential.

How Seam Sealing Works in Apparel

Seam sealing in apparel involves applying a waterproof tape or liquid compound over stitched seams to block water penetration and enhance garment waterproofing. This process fills needle holes and saturates thread openings, creating a continuous barrier that prevents moisture ingress while maintaining fabric breathability. Effective seam sealing is essential in outdoor and performance clothing, ensuring durability and protection against harsh weather conditions.

How Taped Seams Enhance Garment Performance

Taped seams enhance garment performance by providing superior waterproofing and durability compared to traditional seam sealing methods. The application of waterproof tape over stitched areas creates a strong barrier against water penetration while maintaining flexibility and breathability. This technology is crucial in high-performance apparel, ensuring long-lasting protection and comfort in extreme weather conditions.

Waterproofing Efficiency: Seam Sealing vs Taped Seams

Seam sealing uses waterproof tape or liquid applied over the stitches to prevent water ingress, offering a high level of waterproof efficiency ideal for heavy rain conditions. Taped seams involve bonding a waterproof strip directly onto the inside of the garment, creating a streamlined barrier that enhances breathability while maintaining strong waterproof protection. While both methods improve garment durability and moisture resistance, taped seams often provide superior long-term waterproofing by eliminating stitch holes more effectively than traditional seam sealing.

Durability and Longevity Comparison

Seam sealing and taped seams both enhance apparel durability by preventing water penetration, but taped seams typically offer superior longevity due to the adhesive film that binds the fabric edges, resisting wear and tear more effectively. Seam sealing involves applying a waterproof coating over stitched seams, which can degrade over time with repeated washing, reducing the garment's waterproof effectiveness. Taped seams maintain structural integrity longer under stress, making them preferable for high-performance outdoor apparel requiring extended durability.

Applications in Outdoor and Technical Apparel

Seam sealing and taped seams play crucial roles in enhancing waterproofing and durability in outdoor and technical apparel. Seam sealing uses specialized adhesives or liquids to fill the needle holes and fabric interstices, making garments like rain jackets and ski wear highly water-resistant without compromising flexibility. Taped seams, often applied using heat or pressure, provide a robust barrier especially effective in high-stress areas like shoulders and underarms, ensuring long-lasting protection in extreme weather conditions.

Comfort and Breathability Considerations

Seam sealing involves applying a waterproof membrane over stitched areas to prevent water penetration, enhancing garment durability while often maintaining breathability through advanced materials. Taped seams utilize adhesive strips over stitches, offering strong waterproofing but potentially reducing ventilation and flexibility, which can affect comfort during extended wear. Choosing between seam sealing and taped seams depends on balancing waterproof performance with the need for breathability and wearer comfort, especially in active apparel.

Cost Implications: Seam Sealing vs Taped Seams

Seam sealing generally incurs lower initial costs due to its simpler application process and reduced material usage, making it a cost-effective choice for budget-conscious apparel manufacturers. Taped seams involve higher expenses because they require specialized tape, heat-pressing machinery, and additional labor, which can increase production time and overall manufacturing costs. Long-term cost considerations include durability and waterproof performance, where taped seams often justify their premium price by providing superior protection and reducing the need for product returns or repairs.

Choosing the Right Solution for Your Apparel Needs

Seam sealing and taped seams both enhance water resistance in apparel but differ in application and durability; seam sealing uses waterproof tape applied over stitch holes, offering robust protection ideal for heavy-duty outdoor gear, while taped seams involve bonding fabric edges together for lighter, flexible waterproofing suitable for activewear. Selecting the right solution requires evaluating fabric type, intended use, and exposure to moisture; performance apparel designed for extreme weather may benefit more from seam sealing, whereas casual waterproof garments or breathable materials often perform better with taped seams. Understanding product specifications like hydrostatic head rating and seam strength helps optimize garment functionality and longevity for your specific apparel needs.

Seam sealing vs Taped seams Infographic

productdif.com

productdif.com