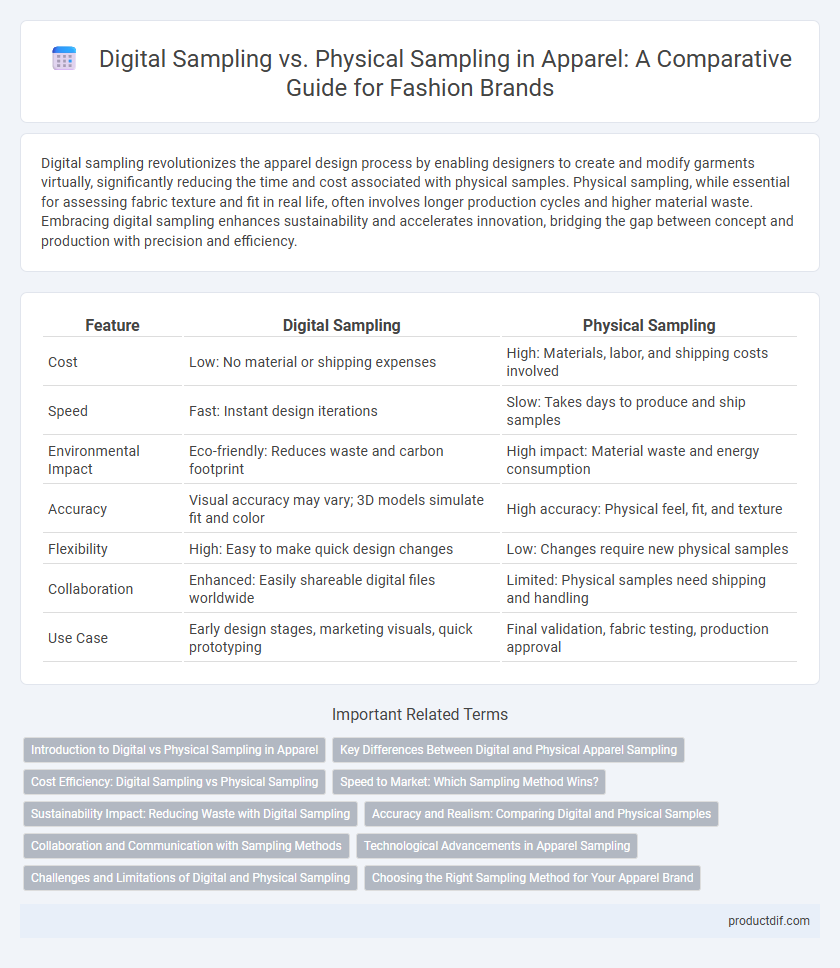

Digital sampling revolutionizes the apparel design process by enabling designers to create and modify garments virtually, significantly reducing the time and cost associated with physical samples. Physical sampling, while essential for assessing fabric texture and fit in real life, often involves longer production cycles and higher material waste. Embracing digital sampling enhances sustainability and accelerates innovation, bridging the gap between concept and production with precision and efficiency.

Table of Comparison

| Feature | Digital Sampling | Physical Sampling |

|---|---|---|

| Cost | Low: No material or shipping expenses | High: Materials, labor, and shipping costs involved |

| Speed | Fast: Instant design iterations | Slow: Takes days to produce and ship samples |

| Environmental Impact | Eco-friendly: Reduces waste and carbon footprint | High impact: Material waste and energy consumption |

| Accuracy | Visual accuracy may vary; 3D models simulate fit and color | High accuracy: Physical feel, fit, and texture |

| Flexibility | High: Easy to make quick design changes | Low: Changes require new physical samples |

| Collaboration | Enhanced: Easily shareable digital files worldwide | Limited: Physical samples need shipping and handling |

| Use Case | Early design stages, marketing visuals, quick prototyping | Final validation, fabric testing, production approval |

Introduction to Digital vs Physical Sampling in Apparel

Digital sampling in apparel leverages 3D design software to create virtual prototypes, significantly reducing time and material costs compared to physical sampling, which involves producing actual garments for evaluation. Physical sampling remains essential for tactile assessment and quality control but is more resource-intensive and slower to iterate. Integrating digital sampling accelerates design workflows and enables rapid modifications before committing to physical prototypes.

Key Differences Between Digital and Physical Apparel Sampling

Digital apparel sampling uses 3D software to create virtual prototypes, speeding up design iterations and reducing costs, while physical sampling involves producing actual garments for fit, fabric, and texture evaluation. Digital samples offer instant modifications and sustainable benefits by minimizing material waste, whereas physical samples provide tangible insights critical for assessing garment construction and real-world wearability. Key differences lie in speed, cost-efficiency, environmental impact, and the ability to test physical attributes versus visual accuracy.

Cost Efficiency: Digital Sampling vs Physical Sampling

Digital sampling significantly reduces costs by eliminating expenses related to materials, shipping, and labor associated with physical prototypes. Physical sampling requires repeated production runs, leading to increased fabric waste and higher manufacturing costs. Brands adopting digital sampling accelerate design iterations while maintaining budget efficiency through virtual prototypes.

Speed to Market: Which Sampling Method Wins?

Digital sampling accelerates speed to market by enabling virtual prototypes that can be reviewed and modified instantly, eliminating the days or weeks required for physical sample production. Physical sampling often causes delays due to manufacturing lead times and shipping logistics, which can impede timely decision-making in fast-paced apparel cycles. Brands leveraging digital sampling experience faster iteration, reduced costs, and improved agility, making it the dominant method for rapid product development.

Sustainability Impact: Reducing Waste with Digital Sampling

Digital sampling in apparel significantly reduces waste by eliminating the need for multiple physical prototypes, which traditionally consume fabric and generate discarded materials. This technology enables designers to visualize and modify garments virtually, minimizing physical resources and lowering the industry's environmental footprint. By adopting digital sampling, brands contribute to sustainability goals through decreased water, energy usage, and carbon emissions associated with fabric production and sample transportation.

Accuracy and Realism: Comparing Digital and Physical Samples

Digital sampling in apparel offers high accuracy by enabling precise color matching and virtual fabric simulations, reducing errors in production phases. Physical sampling provides unmatched realism through tactile evaluation and true-to-life textures, which digital methods still strive to replicate fully. Combining both approaches enhances design validation by balancing digital efficiency with physical authenticity.

Collaboration and Communication with Sampling Methods

Digital sampling enhances collaboration by enabling instant sharing and real-time feedback on 3D garment prototypes across global teams, reducing time and costs associated with physical samples. Physical sampling requires tactile examination and face-to-face communication, often resulting in longer turnaround times due to shipping and production delays. Integrating digital tools with physical sampling frameworks improves accuracy in design decisions and streamlines communication between designers, manufacturers, and suppliers.

Technological Advancements in Apparel Sampling

Technological advancements in apparel sampling have revolutionized the industry by enabling digital sampling to reduce time and costs compared to traditional physical sampling methods. Digital sampling utilizes 3D modeling software and virtual prototyping tools, allowing designers to visualize garments with precise texture, fit, and color without producing physical samples. These innovations enhance sustainability by minimizing material waste and accelerate the product development lifecycle in fashion brands and manufacturers.

Challenges and Limitations of Digital and Physical Sampling

Digital sampling faces challenges such as limited tactile feedback, color accuracy issues, and the high cost of advanced software and hardware, which can hinder precise fabric simulation and texture representation. Physical sampling involves time-consuming production cycles, high material waste, and increased labor costs, making rapid prototyping and iterative design less efficient. Both methods struggle with achieving perfect design validation, impacting decision-making speed and sustainability in apparel development.

Choosing the Right Sampling Method for Your Apparel Brand

Digital sampling accelerates the apparel design process by creating accurate 3D prototypes, reducing costs and material waste while enabling quick design iterations. Physical sampling provides tangible assessment of fabric quality, color accuracy, and fit, essential for finalizing production details in high-stakes collections. Apparel brands must weigh factors like budget, timeline, and product complexity to choose the optimal sampling method that balances innovation with precision.

Digital Sampling vs Physical Sampling Infographic

productdif.com

productdif.com