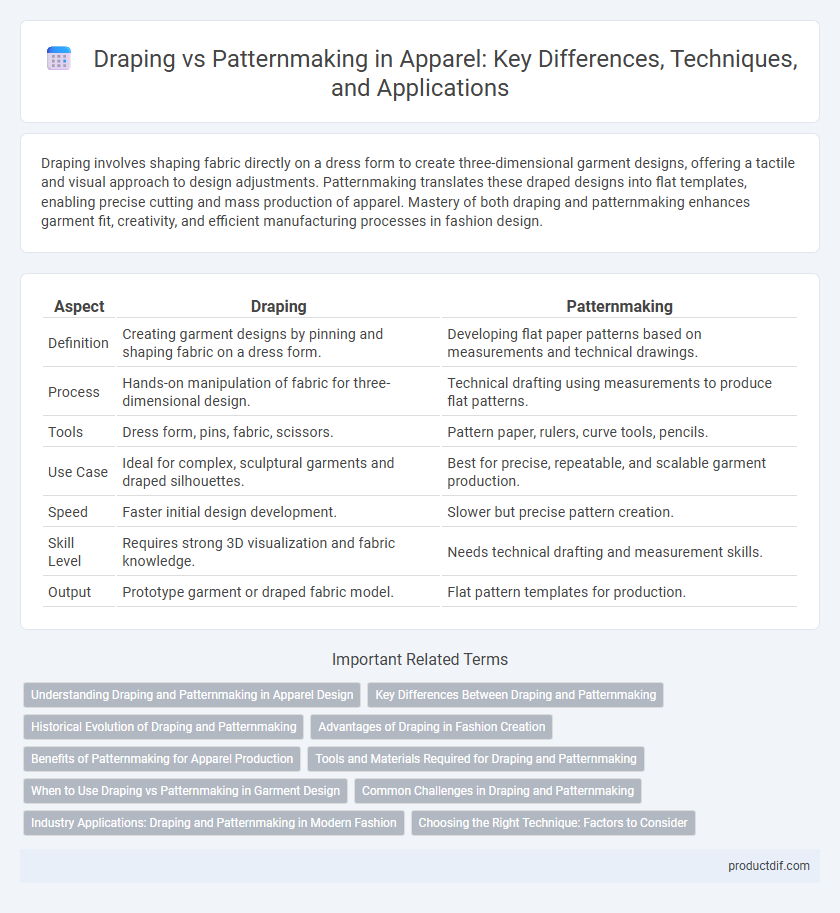

Draping involves shaping fabric directly on a dress form to create three-dimensional garment designs, offering a tactile and visual approach to design adjustments. Patternmaking translates these draped designs into flat templates, enabling precise cutting and mass production of apparel. Mastery of both draping and patternmaking enhances garment fit, creativity, and efficient manufacturing processes in fashion design.

Table of Comparison

| Aspect | Draping | Patternmaking |

|---|---|---|

| Definition | Creating garment designs by pinning and shaping fabric on a dress form. | Developing flat paper patterns based on measurements and technical drawings. |

| Process | Hands-on manipulation of fabric for three-dimensional design. | Technical drafting using measurements to produce flat patterns. |

| Tools | Dress form, pins, fabric, scissors. | Pattern paper, rulers, curve tools, pencils. |

| Use Case | Ideal for complex, sculptural garments and draped silhouettes. | Best for precise, repeatable, and scalable garment production. |

| Speed | Faster initial design development. | Slower but precise pattern creation. |

| Skill Level | Requires strong 3D visualization and fabric knowledge. | Needs technical drafting and measurement skills. |

| Output | Prototype garment or draped fabric model. | Flat pattern templates for production. |

Understanding Draping and Patternmaking in Apparel Design

Draping in apparel design involves manipulating fabric directly on a dress form to create the garment's silhouette, allowing designers to visualize and adjust shapes in real-time. Patternmaking translates these draped designs into precise two-dimensional templates, enabling consistent production and fitting. Mastering both techniques is essential for creating well-fitted garments that balance creativity with technical accuracy in fashion design.

Key Differences Between Draping and Patternmaking

Draping involves creating garment designs by manipulating fabric directly on a dress form, allowing designers to visualize shapes and contours in three dimensions. Patternmaking translates these draped designs or sketches into flat templates used to cut fabric, focusing on precise measurements and garment construction. The key difference lies in draping's emphasis on fabric manipulation and organic design development, whereas patternmaking centers on technical accuracy and replication of garment pieces.

Historical Evolution of Draping and Patternmaking

Draping originated in ancient civilizations such as Egypt and Greece, where fabric was manually arranged on bodies to create garments without pre-made templates, reflecting early human innovation in clothing design. Patternmaking emerged during the Renaissance in Europe, formalizing garment construction through precise measurements and paper templates, revolutionizing clothing production with consistency and repeatability. This shift from draping to patternmaking marks a critical evolution in apparel history, blending artistry with technical precision to meet growing fashion demands.

Advantages of Draping in Fashion Creation

Draping in fashion creation offers designers immediate visual and tactile feedback, enabling real-time adjustments to fabric on a three-dimensional form, which enhances creativity and fit accuracy. It facilitates the exploration of fabric behavior and texture, allowing for the creation of unique silhouettes that are difficult to envision through flat patternmaking. This hands-on technique accelerates prototyping, reduces the need for multiple paper patterns, and improves the overall design innovation process.

Benefits of Patternmaking for Apparel Production

Patternmaking streamlines apparel production by providing precise garment templates that ensure consistent sizing and fit across multiple units. It reduces material waste and production time by allowing for accurate fabric cutting and minimizing errors during assembly. This method enhances design reproducibility, making it ideal for mass production and quality control in fashion manufacturing.

Tools and Materials Required for Draping and Patternmaking

Draping requires essential tools such as dress forms, muslin fabric, pins, scissors, and marking tools to contour fabric directly onto a mannequin, creating three-dimensional garment designs. Patternmaking relies heavily on materials like pattern paper, rulers, curve tools, pencils, and cutting tools to draft flat templates that serve as blueprints for garment construction. Both techniques demand precision equipment, but draping emphasizes fabric manipulation on a form, while patternmaking focuses on accurate flat pattern creation.

When to Use Draping vs Patternmaking in Garment Design

Draping is ideal for designers seeking organic, three-dimensional garment shaping directly on a dress form, providing immediate visualization of fabric flow and fit. Patternmaking excels in precision and reproducibility, allowing for detailed flat templates that ensure consistent sizing and efficient mass production. When to use draping versus patternmaking depends on the design phase: draping suits early-stage conceptual exploration, while patternmaking is essential for technical accuracy and scalable garment construction.

Common Challenges in Draping and Patternmaking

Draping often faces challenges such as fabric distortion and difficulty in translating 3D designs into flat patterns, which can lead to inaccuracies in garment fit. Patternmaking struggles with precise measurement translation and the complexity of creating patterns that accommodate diverse body shapes, often resulting in fitting issues. Both processes require a high level of skill and experience to overcome obstacles related to fabric behavior, body contours, and design interpretation.

Industry Applications: Draping and Patternmaking in Modern Fashion

Draping involves shaping fabric directly on a mannequin to create custom garment designs, widely used in haute couture and luxury fashion for precise fit and innovative silhouettes. Patternmaking translates draped designs into flat templates, essential for mass production and ensuring consistency across large apparel manufacturing. Both techniques are integral in modern fashion, blending creativity with scalability to meet diverse industry demands from bespoke tailoring to large-scale retail.

Choosing the Right Technique: Factors to Consider

Choosing between draping and patternmaking depends on the fabric type, design complexity, and desired fit precision. Draping suits designers seeking a three-dimensional, intuitive approach for fluid or intricate garments, while patternmaking excels in creating precise, repeatable templates for mass production. Understanding end-use, production scale, and material behavior guides the optimal technique selection in apparel design.

Draping vs Patternmaking Infographic

productdif.com

productdif.com