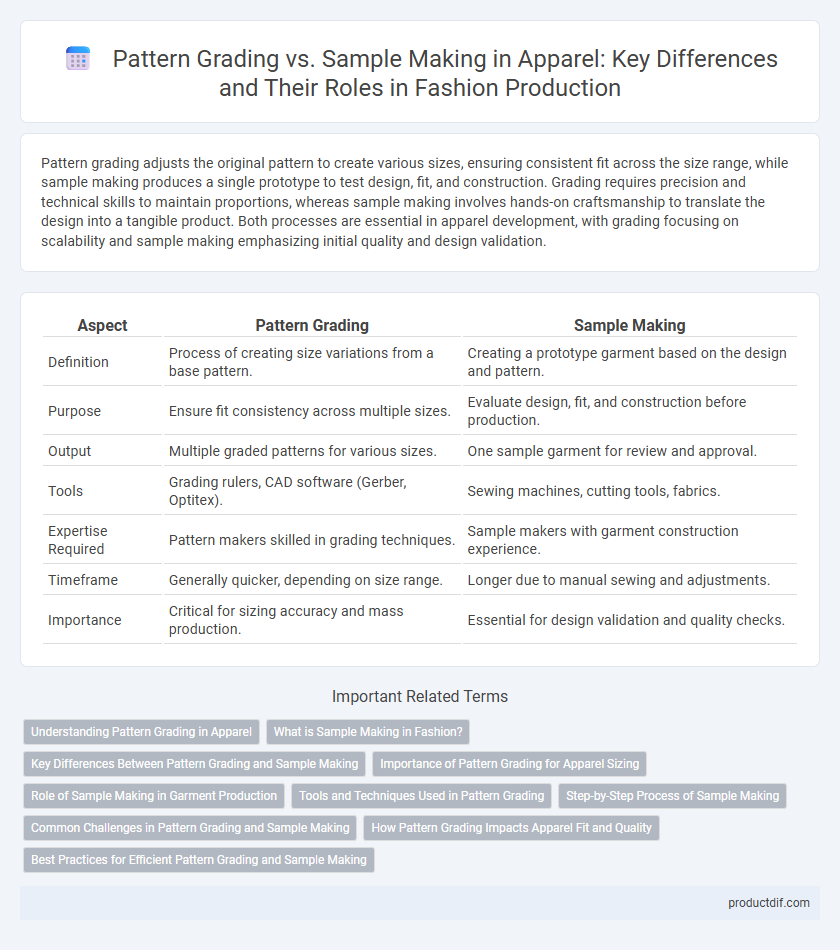

Pattern grading adjusts the original pattern to create various sizes, ensuring consistent fit across the size range, while sample making produces a single prototype to test design, fit, and construction. Grading requires precision and technical skills to maintain proportions, whereas sample making involves hands-on craftsmanship to translate the design into a tangible product. Both processes are essential in apparel development, with grading focusing on scalability and sample making emphasizing initial quality and design validation.

Table of Comparison

| Aspect | Pattern Grading | Sample Making |

|---|---|---|

| Definition | Process of creating size variations from a base pattern. | Creating a prototype garment based on the design and pattern. |

| Purpose | Ensure fit consistency across multiple sizes. | Evaluate design, fit, and construction before production. |

| Output | Multiple graded patterns for various sizes. | One sample garment for review and approval. |

| Tools | Grading rulers, CAD software (Gerber, Optitex). | Sewing machines, cutting tools, fabrics. |

| Expertise Required | Pattern makers skilled in grading techniques. | Sample makers with garment construction experience. |

| Timeframe | Generally quicker, depending on size range. | Longer due to manual sewing and adjustments. |

| Importance | Critical for sizing accuracy and mass production. | Essential for design validation and quality checks. |

Understanding Pattern Grading in Apparel

Pattern grading in apparel involves systematically increasing or decreasing the size of a base pattern to create a full range of sizes, ensuring consistent fit and proportions across the collection. It uses precise measurements and specialized software to maintain garment integrity while scaling designs for different body dimensions. Mastery of pattern grading enhances production efficiency and minimizes fitting errors in mass garment manufacturing.

What is Sample Making in Fashion?

Sample making in fashion involves creating the first physical prototype of a design, allowing designers and manufacturers to evaluate fit, fabric, and construction before mass production. This process translates technical sketches and specifications into a tangible garment, ensuring design accuracy and quality control. Sample making is crucial for identifying potential issues and making necessary adjustments to meet production standards.

Key Differences Between Pattern Grading and Sample Making

Pattern grading involves scaling a base pattern to create various sizes, ensuring consistent fit across a size range, while sample making focuses on constructing a physical prototype garment to evaluate design, fabric, and fit. Pattern grading requires technical precision with measurement increments, whereas sample making emphasizes craftsmanship and material handling to validate the pattern's practical application. These processes are crucial in apparel production, with grading optimizing size variations and sample making confirming design feasibility before mass manufacturing.

Importance of Pattern Grading for Apparel Sizing

Pattern grading is essential for apparel sizing as it ensures consistent fit across multiple sizes by systematically increasing or decreasing the base pattern's dimensions. Accurate pattern grading improves production efficiency, reduces fit issues during sample making, and supports size inclusivity by catering to diverse body measurements. Implementing precise grading techniques enhances garment quality, minimizes returns, and boosts customer satisfaction in the fashion industry.

Role of Sample Making in Garment Production

Sample making plays a crucial role in garment production by transforming design concepts into tangible prototypes, allowing for assessment of fit, fabric performance, and overall aesthetic before mass manufacturing. It ensures that any adjustments in construction, sizing, or material can be identified and implemented early, reducing costly errors and production delays. Effective sample making bridges the gap between pattern grading and final production, enhancing quality control and customer satisfaction.

Tools and Techniques Used in Pattern Grading

Pattern grading relies heavily on specialized tools such as grading rulers, digitizing tablets, and advanced CAD software to accurately scale base patterns to various sizes. Techniques like manual overlay methods and computer-aided grading algorithms ensure precise adjustments while maintaining garment proportions and design integrity. These tools and techniques streamline the transition from sample making to mass production by enabling efficient size range customization and minimizing material waste.

Step-by-Step Process of Sample Making

Sample making in apparel involves creating a physical prototype from a base pattern to evaluate fit, design, and construction. The process begins with pattern adjustments and fabric selection, followed by cutting the fabric pieces accurately and sewing them together to form the initial sample. Final steps include fitting sessions, detailed inspections, and necessary modifications to perfect the garment before mass production.

Common Challenges in Pattern Grading and Sample Making

Common challenges in pattern grading include maintaining accurate proportions across sizes, ensuring fit consistency, and avoiding distortion of design details. Sample making faces difficulties such as selecting appropriate fabrics that mimic final production materials, aligning pattern pieces precisely, and addressing fit issues revealed during garment trials. Both processes require meticulous attention to detail to prevent costly errors in mass production.

How Pattern Grading Impacts Apparel Fit and Quality

Pattern grading directly affects apparel fit by systematically adjusting base patterns to create sizes that maintain proportionality and design integrity across a size range. Proper grading ensures consistent garment dimensions, improving overall quality by reducing fitting issues such as tightness or looseness in specific areas. Accurate grading reduces material waste and production errors, leading to enhanced durability and customer satisfaction in finished apparel products.

Best Practices for Efficient Pattern Grading and Sample Making

Efficient pattern grading requires precise measurement scaling techniques using digital tools like CAD software to maintain garment proportions across sizes, ensuring consistent fit. Sample making benefits from prototyping with high-quality fabrics and iterative fitting sessions to identify necessary adjustments before mass production. Integrating pattern grading and sample making workflows reduces errors, accelerates turnaround times, and improves overall apparel quality.

Pattern Grading vs Sample Making Infographic

productdif.com

productdif.com