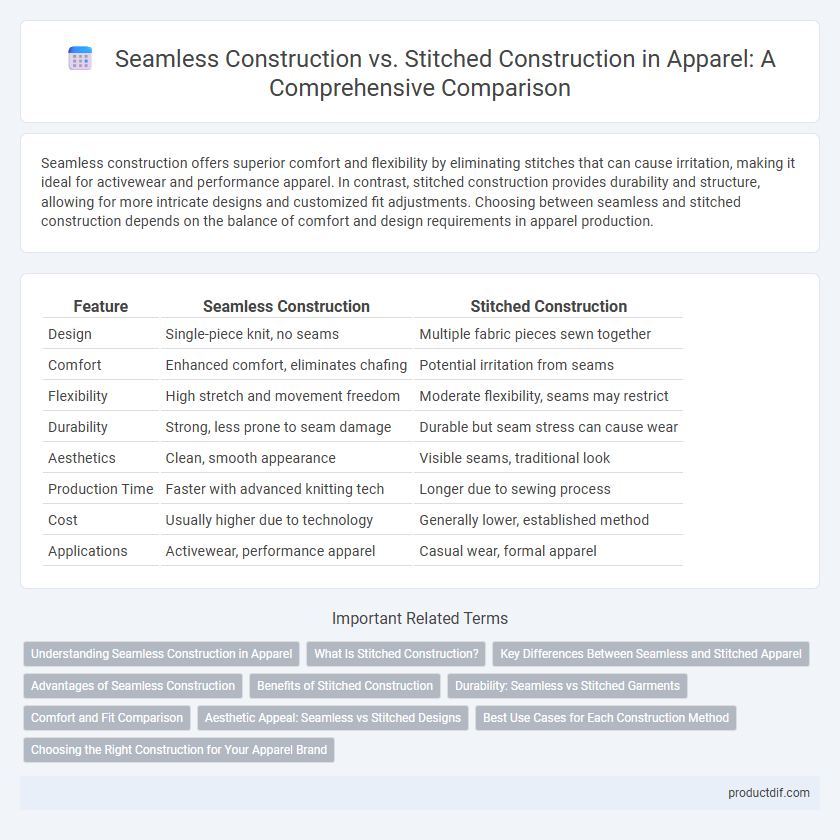

Seamless construction offers superior comfort and flexibility by eliminating stitches that can cause irritation, making it ideal for activewear and performance apparel. In contrast, stitched construction provides durability and structure, allowing for more intricate designs and customized fit adjustments. Choosing between seamless and stitched construction depends on the balance of comfort and design requirements in apparel production.

Table of Comparison

| Feature | Seamless Construction | Stitched Construction |

|---|---|---|

| Design | Single-piece knit, no seams | Multiple fabric pieces sewn together |

| Comfort | Enhanced comfort, eliminates chafing | Potential irritation from seams |

| Flexibility | High stretch and movement freedom | Moderate flexibility, seams may restrict |

| Durability | Strong, less prone to seam damage | Durable but seam stress can cause wear |

| Aesthetics | Clean, smooth appearance | Visible seams, traditional look |

| Production Time | Faster with advanced knitting tech | Longer due to sewing process |

| Cost | Usually higher due to technology | Generally lower, established method |

| Applications | Activewear, performance apparel | Casual wear, formal apparel |

Understanding Seamless Construction in Apparel

Seamless construction in apparel involves creating garments without traditional stitched seams, using techniques like circular knitting or bonding to produce a smooth, continuous fabric. This method enhances comfort by reducing irritation and offers a better fit through contouring to the body's shape. Brands leveraging seamless technology often highlight benefits such as increased durability, lightweight feel, and improved breathability compared to stitched construction.

What Is Stitched Construction?

Stitched construction in apparel refers to garments made by sewing together multiple fabric pieces using needle and thread, creating seams that join different panels. This traditional method allows for intricate designs, tailored fits, and structural support but may lead to discomfort due to seam lines and potential chafing. Common in suits, jeans, and shirts, stitched construction remains preferred for its durability and ability to shape garments precisely.

Key Differences Between Seamless and Stitched Apparel

Seamless construction in apparel utilizes advanced knitting technology to create garments without traditional seams, enhancing comfort, flexibility, and reducing skin irritation compared to stitched construction. Stitched apparel relies on cut fabric pieces sewn together, offering design versatility and structural support but often contains multiple seams that may cause discomfort during prolonged wear. Key differences include seam presence, fit customization, manufacturing complexity, and overall garment durability, influencing performance and user experience in activewear and casual clothing.

Advantages of Seamless Construction

Seamless construction offers superior comfort by eliminating irritating seams that can cause chafing during movement, making it ideal for activewear and performance apparel. This method enhances garment durability by reducing weak points where stitches can unravel, resulting in longer-lasting products. Furthermore, seamless technology allows for greater design flexibility and a more streamlined fit, improving both aesthetics and functionality in modern apparel.

Benefits of Stitched Construction

Stitched construction in apparel offers enhanced durability by securely joining fabric pieces, ensuring garments withstand repeated wear and washing. This method allows for greater design versatility and precise shaping, accommodating intricate patterns and tailoring details. The reinforced seams also provide improved fit and structure, making stitched garments ideal for tailored and high-performance clothing.

Durability: Seamless vs Stitched Garments

Seamless construction enhances garment durability by eliminating stitch holes that can weaken fabric and cause premature wear. Stitched construction, while traditional, creates stress points along seams that are prone to fraying and tearing over time. Advanced seamless knitting techniques improve elasticity and strength, resulting in longer-lasting apparel compared to conventional stitched garments.

Comfort and Fit Comparison

Seamless construction offers superior comfort by eliminating seams that can cause irritation or chafing during movement, making it ideal for activewear and prolonged wear. Stitched construction provides more structured fit options and design flexibility but may sacrifice some comfort due to raised seams and potential pressure points. In terms of fit, seamless garments adapt better to body contours, ensuring a snug yet flexible fit, while stitched pieces often deliver more tailored shapes with defined edges.

Aesthetic Appeal: Seamless vs Stitched Designs

Seamless construction in apparel offers a smooth, uninterrupted silhouette that enhances the garment's aesthetic appeal by eliminating visible stitches and providing a sleek, modern look. Stitched construction, while traditional, allows for intricate patterns and detailing through visible seams, which can add a tailored, textured character to the design. The choice between seamless and stitched designs significantly influences the visual impact and style, catering to preferences for minimalism or detailed craftsmanship.

Best Use Cases for Each Construction Method

Seamless construction excels in activewear and performance apparel due to its enhanced flexibility, reduced chafing, and lightweight design, making it ideal for high-movement activities like running and yoga. Stitched construction is preferred in formal wear and denim for its durability, structured fit, and ability to incorporate intricate patterns and details, providing a classic and tailored appearance. Choosing between seamless and stitched construction depends on the garment's intended use, prioritizing comfort and stretch for athletic wear or robust, detailed designs for everyday and formal outfits.

Choosing the Right Construction for Your Apparel Brand

Seamless construction offers enhanced comfort, flexibility, and reduced irritation, making it ideal for activewear and performance apparel targeting modern consumers. Stitched construction provides durability, structural integrity, and a classic tailored look preferred in formal, denim, or casual wear collections. Evaluating your brand's target market, design aesthetics, and production volume helps determine whether seamless innovation or traditional stitching best aligns with your apparel's functional and stylistic goals.

Seamless Construction vs Stitched Construction Infographic

productdif.com

productdif.com