Screen printing offers vibrant, long-lasting designs ideal for bulk production on cotton fabrics, while sublimation printing excels at producing detailed, full-color images on polyester garments with a soft, breathable finish. Screen printing involves applying ink through a stencil, creating durable textures that withstand washing, whereas sublimation uses heat to infuse dye directly into the fabric, ensuring no fading or peeling. Choosing between these methods depends on fabric type, design complexity, and production volume, with screen printing favored for simple graphics and sublimation preferred for intricate, multicolor designs.

Table of Comparison

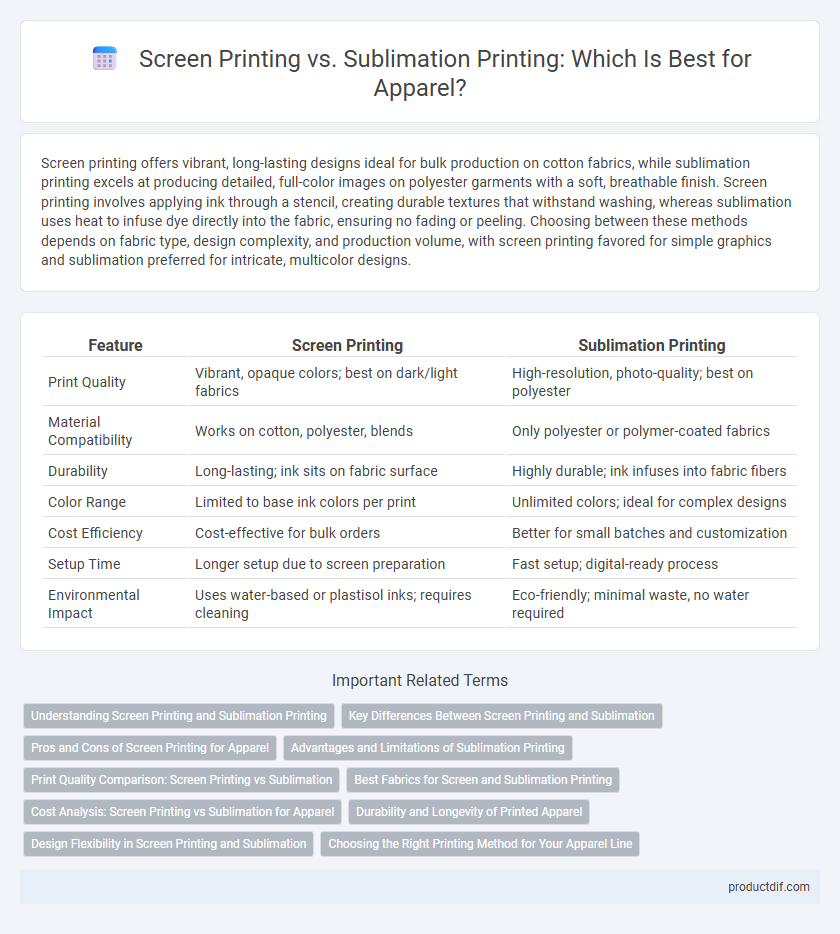

| Feature | Screen Printing | Sublimation Printing |

|---|---|---|

| Print Quality | Vibrant, opaque colors; best on dark/light fabrics | High-resolution, photo-quality; best on polyester |

| Material Compatibility | Works on cotton, polyester, blends | Only polyester or polymer-coated fabrics |

| Durability | Long-lasting; ink sits on fabric surface | Highly durable; ink infuses into fabric fibers |

| Color Range | Limited to base ink colors per print | Unlimited colors; ideal for complex designs |

| Cost Efficiency | Cost-effective for bulk orders | Better for small batches and customization |

| Setup Time | Longer setup due to screen preparation | Fast setup; digital-ready process |

| Environmental Impact | Uses water-based or plastisol inks; requires cleaning | Eco-friendly; minimal waste, no water required |

Understanding Screen Printing and Sublimation Printing

Screen printing uses stencils and ink layers to create durable, vibrant designs ideal for bulk orders on cotton and polyester garments. Sublimation printing involves transferring dye onto polyester fabric using heat, producing detailed, full-color images that become part of the fabric itself, making it perfect for all-over designs. Both techniques offer unique advantages depending on fabric type, design complexity, and production volume needs.

Key Differences Between Screen Printing and Sublimation

Screen printing uses ink pushed through a stencil on a mesh screen to create vibrant, long-lasting designs ideal for bold colors and simple graphics on cotton fabrics. Sublimation printing chemically bonds dye to polyester fibers, offering high-resolution, full-color images with intricate detail and a soft feel that won't crack or peel. Screen printing excels in cost-effective bulk production, while sublimation shines in producing detailed, multicolor designs suited for polyester apparel and small batch runs.

Pros and Cons of Screen Printing for Apparel

Screen printing offers vibrant colors and durability, making it ideal for bulk orders and designs with few colors on apparel such as t-shirts and hoodies. However, it involves higher setup costs and is less efficient for complex or multi-color designs, leading to longer production times compared to digital methods. Its strong ink adhesion ensures lasting prints on fabrics but may feel heavier and less breathable on garments.

Advantages and Limitations of Sublimation Printing

Sublimation printing offers vibrant, long-lasting colors with a smooth, fabric-embedded finish that resists fading and cracking, making it ideal for polyester and synthetic materials. Limitations include its incompatibility with natural fibers like cotton and the requirement for white or light-colored substrates to achieve accurate color reproduction. This method excels in producing detailed, full-color designs but is less effective on dark fabrics and limited to thinner materials suitable for heat transfer.

Print Quality Comparison: Screen Printing vs Sublimation

Screen printing produces vibrant, opaque prints with excellent durability on a wide range of fabrics, making it ideal for bold designs and solid colors. Sublimation printing excels in producing high-resolution, full-color, and intricate designs with smooth gradients, but it works best on polyester or polymer-coated materials. While screen printing offers superior color opacity and longevity, sublimation provides unmatched detail and color vibrancy on suitable apparel substrates.

Best Fabrics for Screen and Sublimation Printing

Screen printing works best on natural fabrics like cotton and blends with high cotton content due to its ability to hold vibrant ink layers and durability through washes. Sublimation printing requires polyester or polyester-blend fabrics, as the dye bonds chemically with synthetic fibers to produce vivid, long-lasting colors without cracking or fading. For optimal results, choose 100% cotton or high-cotton blends for screen printing and 100% polyester or fabrics with at least 65% polyester for sublimation printing.

Cost Analysis: Screen Printing vs Sublimation for Apparel

Screen printing offers lower costs for bulk apparel orders due to economy of scale, making it ideal for large runs with limited color palettes. Sublimation printing incurs higher upfront expenses because of specialized equipment and inks but enables vibrant, full-color designs with no additional cost per color. For small, complex, or highly detailed orders requiring extensive color gradients, sublimation becomes more cost-effective despite initial investments.

Durability and Longevity of Printed Apparel

Screen printing offers exceptional durability and longevity, with ink layers that resist fading, cracking, and peeling even after numerous wash cycles, making it ideal for high-volume, long-lasting apparel. Sublimation printing infuses dye directly into polyester fibers, resulting in vibrant, permanent prints that won't fade or deteriorate over time but may be less effective on natural fabrics. For long-term wear and durability, screen printing excels on cotton and blended fabrics, while sublimation provides superior colorfastness on polyester materials.

Design Flexibility in Screen Printing and Sublimation

Screen printing offers excellent design flexibility for bold, vibrant artwork with solid colors and sharp contrasts, ideal for simple to moderately complex graphics on various fabrics. Sublimation printing excels in producing highly detailed, full-color designs with smooth gradients and intricate patterns, seamlessly integrating into polyester fabrics for all-over prints. Both methods provide unique advantages, with screen printing best suited for durable, layered designs, while sublimation caters to photorealistic and continuous-tone imagery.

Choosing the Right Printing Method for Your Apparel Line

Screen printing offers vibrant colors and durability, making it ideal for bold designs and large production runs, while sublimation printing excels in producing intricate, full-color graphics on polyester fabrics with a soft feel. Consider the type of fabric, design complexity, and order volume when choosing between screen printing's cost-effectiveness for bulk orders and sublimation's superior detail for small batches or custom pieces. Selecting the appropriate method impacts print quality, garment longevity, and overall production costs for your apparel line.

Screen Printing vs Sublimation Printing Infographic

productdif.com

productdif.com