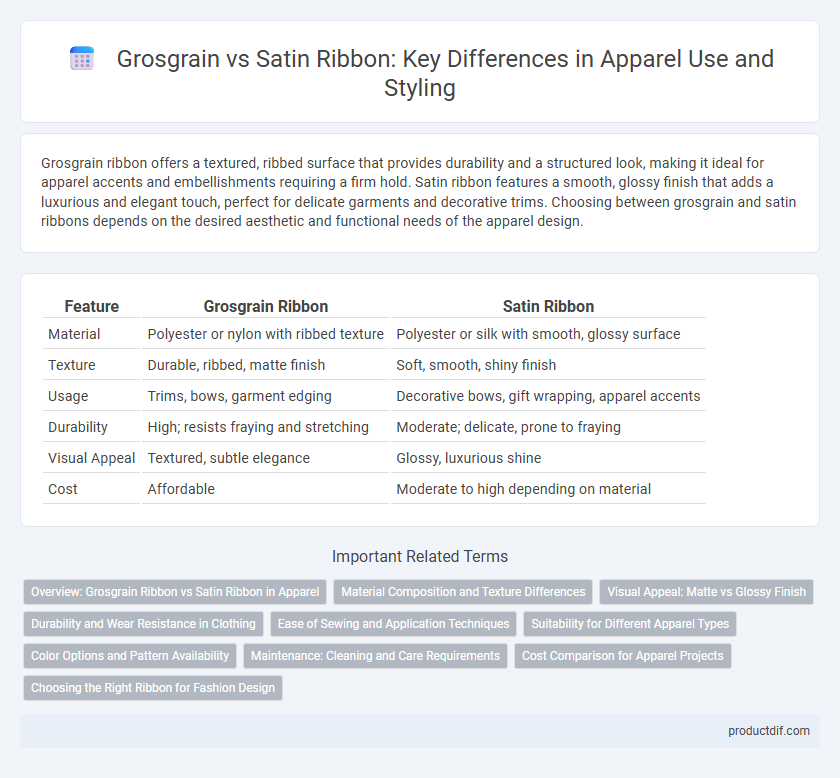

Grosgrain ribbon offers a textured, ribbed surface that provides durability and a structured look, making it ideal for apparel accents and embellishments requiring a firm hold. Satin ribbon features a smooth, glossy finish that adds a luxurious and elegant touch, perfect for delicate garments and decorative trims. Choosing between grosgrain and satin ribbons depends on the desired aesthetic and functional needs of the apparel design.

Table of Comparison

| Feature | Grosgrain Ribbon | Satin Ribbon |

|---|---|---|

| Material | Polyester or nylon with ribbed texture | Polyester or silk with smooth, glossy surface |

| Texture | Durable, ribbed, matte finish | Soft, smooth, shiny finish |

| Usage | Trims, bows, garment edging | Decorative bows, gift wrapping, apparel accents |

| Durability | High; resists fraying and stretching | Moderate; delicate, prone to fraying |

| Visual Appeal | Textured, subtle elegance | Glossy, luxurious shine |

| Cost | Affordable | Moderate to high depending on material |

Overview: Grosgrain Ribbon vs Satin Ribbon in Apparel

Grosgrain ribbon features a ribbed texture with a matte finish, offering durability and a firm structure ideal for trims, bows, and garment reinforcement in apparel. Satin ribbon is smooth, glossy, and soft, providing an elegant, luxurious appearance often used for decorative accents and formal wear embellishments. Both ribbon types serve distinct functional and aesthetic purposes, with grosgrain excelling in strength and satin in sheen.

Material Composition and Texture Differences

Grosgrain ribbon is made from tightly woven fibers, typically polyester or nylon, creating a ribbed texture with distinct horizontal ridges, enhancing durability and grip for apparel applications. Satin ribbon, composed of silk, polyester, or acetate fibers, features a smooth, glossy surface and a soft texture achieved through a satin weave that reflects light for a luxurious finish. These material compositions and textures determine their suitability, with grosgrain offering structure and resistance, while satin provides elegance and fluidity in garment embellishments.

Visual Appeal: Matte vs Glossy Finish

Grosgrain ribbon features a distinctive matte finish with a ribbed texture that adds depth and a subtle sophistication to apparel designs. Satin ribbon offers a glossy, smooth surface that reflects light, creating a luxurious and elegant appearance ideal for formal wear and decorative accents. Choosing between grosgrain and satin ribbons influences the overall visual appeal by balancing understated texture against vibrant sheen.

Durability and Wear Resistance in Clothing

Grosgrain ribbon exhibits superior durability and wear resistance compared to satin ribbon due to its tightly woven, ribbed texture that withstands friction and tension. Satin ribbon, while offering a smooth and glossy finish, tends to be more prone to fraying and snagging with frequent wear or washing. For long-lasting apparel applications requiring robust structural support, grosgrain ribbon is the preferred choice to maintain integrity over time.

Ease of Sewing and Application Techniques

Grosgrain ribbon features a tightly woven ribbed texture, making it sturdier and easier to sew without slipping, ideal for structured applications like belts and hair accessories. Satin ribbon's smooth, glossy surface can be more slippery during sewing but offers a delicate finish perfect for embellishments and decorative bows. Techniques for grosgrain emphasize straight stitching and reinforced edges, while satin requires careful handling and sometimes interfacings for stability.

Suitability for Different Apparel Types

Grosgrain ribbon is ideal for structured garments like suits and uniforms due to its textured finish and durability, providing strong support and a classic look. Satin ribbon's smooth and shiny surface complements delicate apparel such as evening gowns and lingerie, enhancing elegance and softness. Choosing between grosgrain and satin ribbons depends on the desired finish and garment functionality, with grosgrain suited for sturdy designs and satin for refined, decorative accents.

Color Options and Pattern Availability

Grosgrain ribbon offers a wide range of solid color options and is commonly found with textured, ribbed patterns that add visual interest and durability to apparel designs. Satin ribbon excels in vibrant, glossy color choices and often features smooth, shiny surfaces suitable for elegant patterns, floral prints, or seasonal motifs. Both ribbons cater to unique aesthetic needs, with grosgrain emphasizing texture variety and satin emphasizing rich, lustrous finishes.

Maintenance: Cleaning and Care Requirements

Grosgrain ribbon is more durable and resistant to fraying, making it easier to maintain with simple spot cleaning and gentle hand washing. Satin ribbon requires more delicate care due to its smooth and shiny surface, often needing cold water, mild detergents, and careful ironing on a low setting to prevent damage. Both ribbons benefit from air drying and avoiding harsh chemicals to preserve their texture and appearance.

Cost Comparison for Apparel Projects

Grosgrain ribbon typically costs less than satin ribbon, making it a budget-friendly choice for large-scale apparel projects. Satin ribbon, known for its smooth and glossy finish, usually commands a higher price due to its luxurious appearance and more delicate manufacturing process. For cost-conscious apparel production, grosgrain ribbon offers durability and affordability without sacrificing style.

Choosing the Right Ribbon for Fashion Design

Grosgrain ribbon provides a textured, durable finish ideal for structured garments and accessories, offering excellent grip and stability in designs. Satin ribbon features a smooth, glossy surface that enhances elegance and softness, making it perfect for delicate, flowing fashion pieces or embellishments. Selecting between grosgrain and satin depends on the desired aesthetic and functional needs of the fashion design, balancing texture, sheen, and fabric compatibility.

Grosgrain Ribbon vs Satin Ribbon Infographic

productdif.com

productdif.com