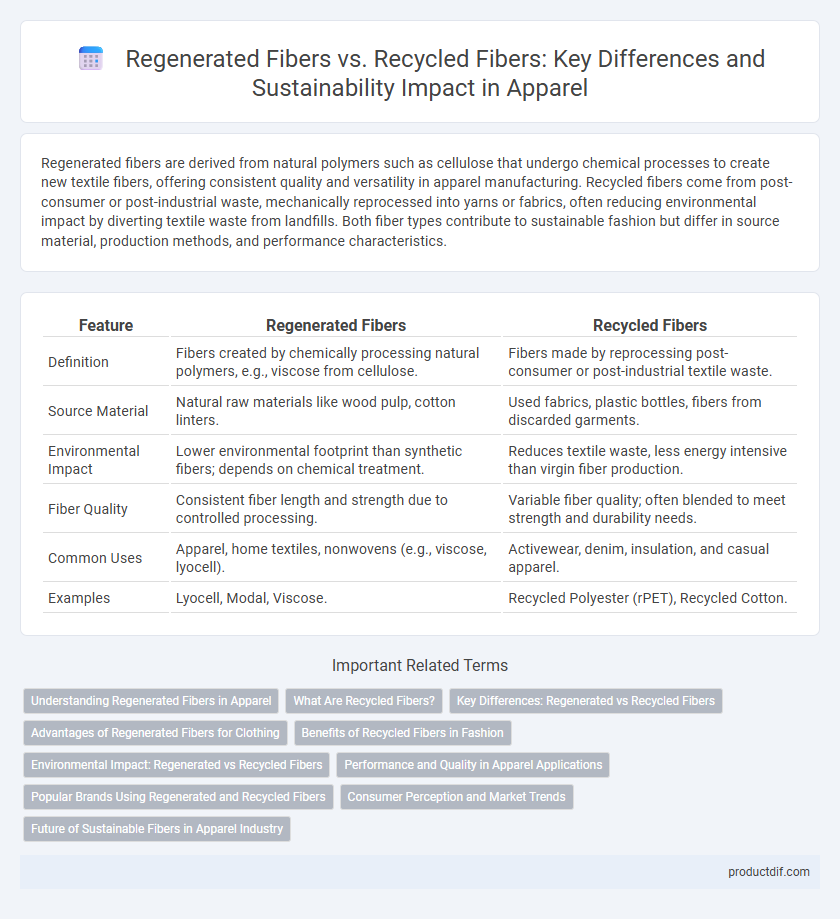

Regenerated fibers are derived from natural polymers such as cellulose that undergo chemical processes to create new textile fibers, offering consistent quality and versatility in apparel manufacturing. Recycled fibers come from post-consumer or post-industrial waste, mechanically reprocessed into yarns or fabrics, often reducing environmental impact by diverting textile waste from landfills. Both fiber types contribute to sustainable fashion but differ in source material, production methods, and performance characteristics.

Table of Comparison

| Feature | Regenerated Fibers | Recycled Fibers |

|---|---|---|

| Definition | Fibers created by chemically processing natural polymers, e.g., viscose from cellulose. | Fibers made by reprocessing post-consumer or post-industrial textile waste. |

| Source Material | Natural raw materials like wood pulp, cotton linters. | Used fabrics, plastic bottles, fibers from discarded garments. |

| Environmental Impact | Lower environmental footprint than synthetic fibers; depends on chemical treatment. | Reduces textile waste, less energy intensive than virgin fiber production. |

| Fiber Quality | Consistent fiber length and strength due to controlled processing. | Variable fiber quality; often blended to meet strength and durability needs. |

| Common Uses | Apparel, home textiles, nonwovens (e.g., viscose, lyocell). | Activewear, denim, insulation, and casual apparel. |

| Examples | Lyocell, Modal, Viscose. | Recycled Polyester (rPET), Recycled Cotton. |

Understanding Regenerated Fibers in Apparel

Regenerated fibers in apparel, such as viscose, lyocell, and modal, are produced by chemically processing natural polymers like cellulose to create new textile fibers with enhanced softness and breathability. Unlike recycled fibers that are made from reprocessed waste materials, regenerated fibers offer a sustainable alternative by transforming raw natural resources into versatile, biodegradable fabrics. These fibers contribute to eco-friendly fashion by reducing reliance on synthetic materials and promoting circularity in the textile industry.

What Are Recycled Fibers?

Recycled fibers are derived from post-consumer or post-industrial textile waste that is processed and transformed into new fiber materials, reducing the need for virgin resources. These fibers maintain the original polymer structure, allowing for the production of new fabrics with lower environmental impact compared to conventional fibers. Common sources include recycled polyester from plastic bottles and recycled cotton from garment scraps, promoting sustainability in apparel manufacturing.

Key Differences: Regenerated vs Recycled Fibers

Regenerated fibers, such as viscose and lyocell, are produced by chemically processing natural raw materials like wood pulp into new fiber forms, while recycled fibers are created by mechanically reprocessing used textiles or plastic waste into fiber. The key difference lies in the source material and production method: regenerated fibers start from natural polymers broken down and reformed, whereas recycled fibers reuse existing fiber fragments, reducing waste and resource consumption. Regenerated fibers offer consistent quality and performance similar to virgin fibers, whereas recycled fibers may vary in quality depending on the source material's condition and processing efficiency.

Advantages of Regenerated Fibers for Clothing

Regenerated fibers in apparel offer superior softness, breathability, and moisture-wicking properties compared to recycled fibers, enhancing wearer comfort. These fibers, often derived from cellulose sources like bamboo or eucalyptus, promote sustainability by utilizing renewable raw materials and reducing reliance on synthetic fabrics. Their biodegradability and dye affinity provide eco-friendly options without compromising fabric quality or visual appeal.

Benefits of Recycled Fibers in Fashion

Recycled fibers in fashion significantly reduce landfill waste and lower the demand for virgin raw materials, minimizing environmental impact. These fibers require less energy and water during production, contributing to more sustainable manufacturing processes. Incorporating recycled fibers supports circular economy principles, enhancing brand appeal and meeting consumer demand for eco-friendly apparel.

Environmental Impact: Regenerated vs Recycled Fibers

Regenerated fibers, derived from natural cellulose sources such as wood pulp, typically have a lower carbon footprint compared to synthetic fibers but still involve chemical processing that can impact water quality. Recycled fibers, often made from post-consumer textiles or plastic waste, significantly reduce landfill contributions and resource extraction, offering a more sustainable option by closing the loop in textile production. Both fibers contribute to environmental sustainability, but recycled fibers generally provide greater benefits by minimizing waste and conserving raw materials.

Performance and Quality in Apparel Applications

Regenerated fibers such as viscose and lyocell offer superior moisture-wicking and breathability compared to recycled fibers, enhancing comfort in apparel applications. Recycled fibers, often derived from pre- or post-consumer waste like PET bottles, provide significant environmental benefits but may exhibit lower tensile strength and durability. Balancing performance and quality, garments using a blend of regenerated and recycled fibers achieve sustainable fashion without compromising wearability and longevity.

Popular Brands Using Regenerated and Recycled Fibers

Popular apparel brands such as Patagonia, Stella McCartney, and Adidas incorporate recycled fibers like PET from plastic bottles into their product lines to promote sustainability. Meanwhile, fast-fashion leaders like H&M and Zara are increasingly using regenerated fibers such as lyocell and modal, derived from wood pulp, to reduce environmental impact. Both recycled and regenerated fibers play crucial roles in the evolving sustainable fabric market, with brands leveraging these materials to appeal to eco-conscious consumers.

Consumer Perception and Market Trends

Regenerated fibers, such as viscose and lyocell, are increasingly favored by consumers for their natural origin and sustainable production process, contributing to a perception of eco-friendliness and luxury. Recycled fibers, often made from post-consumer plastic waste, appeal to environmentally conscious buyers seeking circular fashion solutions and waste reduction. Market trends indicate strong growth for both fiber types, with regenerated fibers gaining traction in premium apparel segments and recycled fibers dominating affordable, mass-market sustainable clothing.

Future of Sustainable Fibers in Apparel Industry

Regenerated fibers, derived from natural raw materials like wood pulp, offer a sustainable alternative by reducing reliance on virgin resources and enabling biodegradability, whereas recycled fibers are produced by reprocessing existing textiles or plastics, minimizing waste and energy consumption. Innovations in fiber technology and circular economy practices are accelerating the adoption of both regenerated and recycled fibers, driving the apparel industry toward greater environmental responsibility. Future developments will emphasize enhancing fiber quality, scalability, and transparency to meet growing consumer demand for eco-friendly and ethically produced garments.

Regenerated fibers vs Recycled fibers Infographic

productdif.com

productdif.com