Direct to garment printing offers vibrant, detailed designs with a soft feel, ideal for cotton and natural fabrics, whereas sublimation printing provides durable, full-color prints best suited for polyester materials. Sublimation infuses ink directly into the fabric, ensuring long-lasting, fade-resistant designs, while direct to garment applies ink on the surface, allowing for more intricate artwork on diverse fabric types. Choosing between the two depends on the desired fabric compatibility, print quality, and durability for your apparel projects.

Table of Comparison

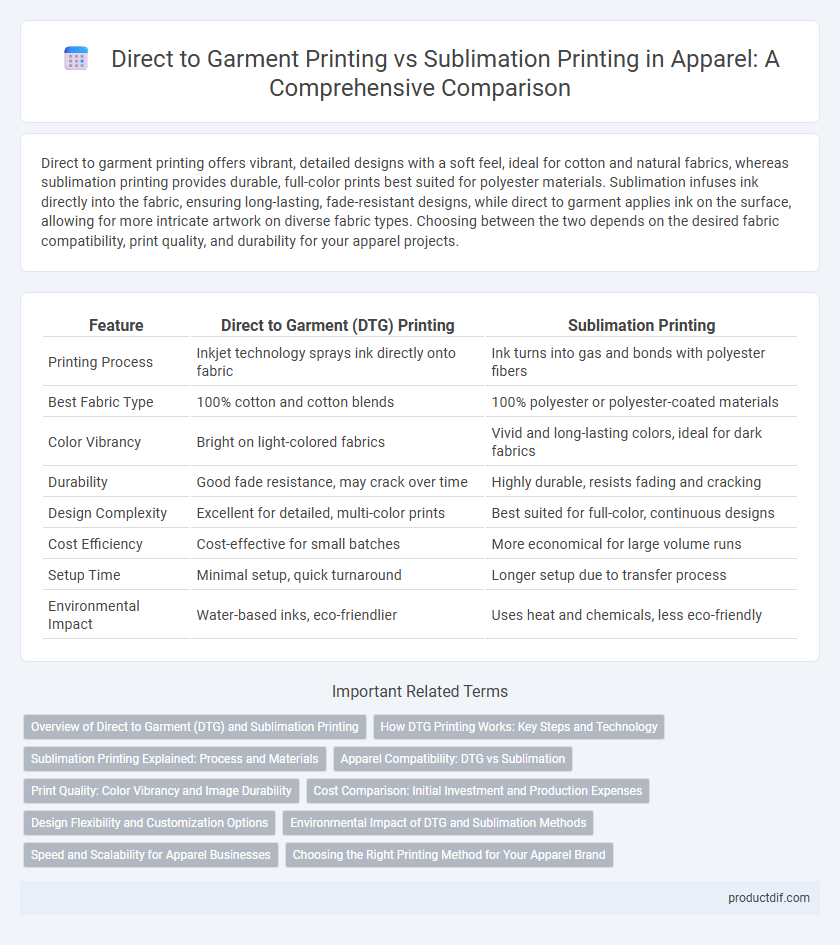

| Feature | Direct to Garment (DTG) Printing | Sublimation Printing |

|---|---|---|

| Printing Process | Inkjet technology sprays ink directly onto fabric | Ink turns into gas and bonds with polyester fibers |

| Best Fabric Type | 100% cotton and cotton blends | 100% polyester or polyester-coated materials |

| Color Vibrancy | Bright on light-colored fabrics | Vivid and long-lasting colors, ideal for dark fabrics |

| Durability | Good fade resistance, may crack over time | Highly durable, resists fading and cracking |

| Design Complexity | Excellent for detailed, multi-color prints | Best suited for full-color, continuous designs |

| Cost Efficiency | Cost-effective for small batches | More economical for large volume runs |

| Setup Time | Minimal setup, quick turnaround | Longer setup due to transfer process |

| Environmental Impact | Water-based inks, eco-friendlier | Uses heat and chemicals, less eco-friendly |

Overview of Direct to Garment (DTG) and Sublimation Printing

Direct to Garment (DTG) printing uses inkjet technology to apply water-based inks directly onto fabric, making it ideal for detailed, full-color designs on cotton or cotton-blend materials. Sublimation printing involves transferring dye onto polyester fabrics via heat, resulting in vibrant, durable prints that are embedded into the fibers rather than sitting on the surface. DTG offers superior performance for small runs and complex artwork, while sublimation excels in producing long-lasting, high-resolution designs on synthetic textiles.

How DTG Printing Works: Key Steps and Technology

Direct to garment (DTG) printing utilizes specialized inkjet technology that sprays water-based inks directly onto fabric fibers, allowing for high-resolution, full-color designs on cotton and cotton-blend garments. Key steps include pre-treatment of the fabric to enhance ink absorption, precise inkjet printing controlled by digital files, and curing with heat to set the design permanently. DTG technology excels in producing intricate artwork with smooth gradients and fine details, making it ideal for small batch or custom apparel production.

Sublimation Printing Explained: Process and Materials

Sublimation printing involves transferring dye onto polyester fabrics using heat and pressure, resulting in vibrant, long-lasting designs that are embedded into the fibers rather than resting on the surface. The process requires polyester or polymer-coated materials to ensure the dye bonds effectively, making it ideal for athletic wear and custom apparel that demands durability and colorfastness. Sublimation printing excels in producing detailed, full-color images without cracking or fading, surpassing direct to garment printing on synthetic textiles.

Apparel Compatibility: DTG vs Sublimation

Direct to Garment (DTG) printing excels with 100% cotton apparel, offering vibrant colors and soft hand feel, while Sublimation printing is limited to polyester fabrics, ideal for sportswear and performance apparel due to its dye-infused, durable prints. DTG provides superior compatibility for natural fibers, ensuring high-quality prints on t-shirts, hoodies, and cotton blends, whereas Sublimation's compatibility is optimal with polyester-rich fabrics, enhancing moisture-wicking and stretch properties. Understanding fabric content is critical when choosing between DTG and Sublimation to achieve longevity, color accuracy, and wear comfort in printed apparel.

Print Quality: Color Vibrancy and Image Durability

Direct to garment printing delivers sharp, vivid colors with excellent detail on cotton fabrics, ensuring high color vibrancy that stands out on casual apparel. Sublimation printing excels in producing vibrant, long-lasting images on polyester materials, embedding the ink into fibers for superior durability and resistance to fading. Both methods offer distinct advantages in print quality, with DTG favoring color richness on natural textiles and sublimation providing unmatched image endurance on synthetic fabrics.

Cost Comparison: Initial Investment and Production Expenses

Direct to garment (DTG) printing requires a higher initial investment with specialized inkjet printers costing between $15,000 and $30,000, but offers lower production costs for small batches due to minimal setup fees. Sublimation printing demands moderate equipment expenses around $2,000 to $7,000 but involves ongoing costs for sublimation inks and transfer paper, making it more cost-effective for high-volume polyester fabrics. Evaluating volume requirements and fabric compatibility is essential to optimize overall expenses in apparel production.

Design Flexibility and Customization Options

Direct to garment printing offers superior design flexibility by enabling vibrant, full-color prints on a wide range of fabrics, including cotton, without color limitations. Sublimation printing excels in customization for polyester garments, producing durable, high-resolution designs infused into the fabric, but it is limited to light-colored, synthetic materials. These differences impact garment choice and design possibilities significantly for apparel brands seeking tailored customization.

Environmental Impact of DTG and Sublimation Methods

Direct to garment (DTG) printing produces less waste by using water-based inks that are biodegradable and require less energy consumption compared to sublimation printing, which involves the use of heat transfers and chemical inks that can release volatile organic compounds (VOCs). Sublimation printing, while vibrant and durable, relies on synthetic polyester fabrics and generates more plastic waste due to transfer sheets and polymer-coated materials. The choice between DTG and sublimation methods significantly affects the environmental footprint, with DTG generally offering a more eco-friendly option for garment production.

Speed and Scalability for Apparel Businesses

Direct to garment (DTG) printing offers faster turnaround times for small to medium apparel orders with minimal setup, making it ideal for quick customizations and on-demand printing. Sublimation printing excels in scalability and high-volume production, delivering vibrant, long-lasting prints best suited for polyester fabrics and large batch runs. Apparel businesses benefit from DTG for rapid prototyping and varied designs, while sublimation supports efficient mass production with superior color consistency.

Choosing the Right Printing Method for Your Apparel Brand

Direct to garment printing excels in producing high-quality, vibrant designs on cotton and natural fibers, ideal for small to medium apparel runs with detailed artwork. Sublimation printing offers superior color durability and works best on polyester blends, making it perfect for athletic wear and all-over prints with complex patterns. Selecting the right printing method depends on fabric type, design complexity, and production volume to ensure optimal quality and cost-efficiency for your apparel brand.

Direct to garment printing vs Sublimation printing Infographic

productdif.com

productdif.com