Digital pattern making revolutionizes apparel design by enabling precise adjustments and faster iterations compared to manual pattern making. It streamlines the workflow with advanced software that reduces errors and material waste, boosting overall efficiency and accuracy. While manual pattern making offers hands-on control and tactile feedback, digital techniques provide scalability and seamless integration with automated cutting technologies.

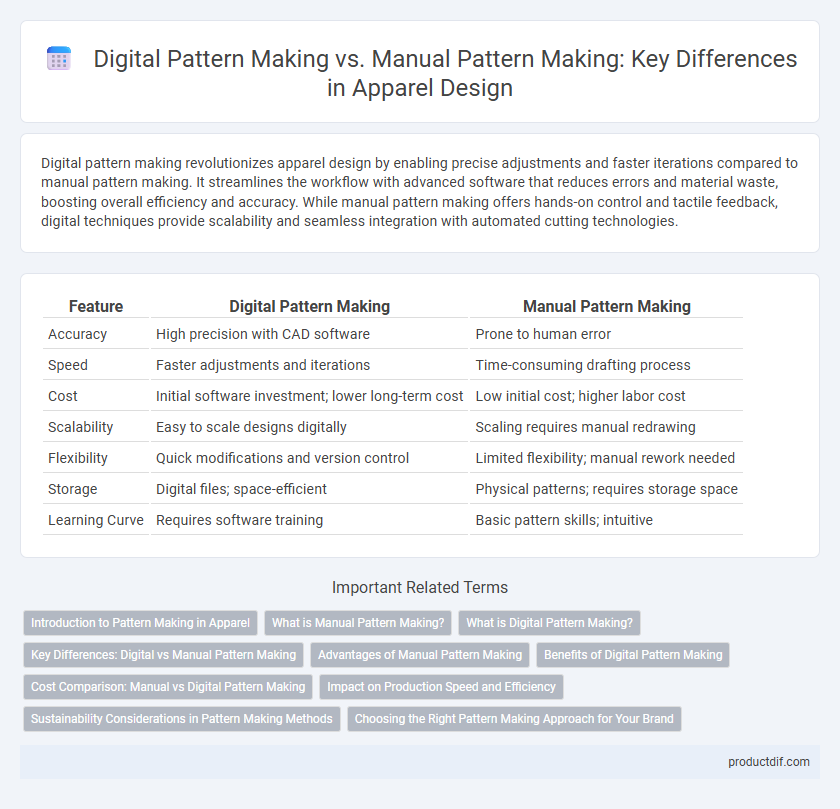

Table of Comparison

| Feature | Digital Pattern Making | Manual Pattern Making |

|---|---|---|

| Accuracy | High precision with CAD software | Prone to human error |

| Speed | Faster adjustments and iterations | Time-consuming drafting process |

| Cost | Initial software investment; lower long-term cost | Low initial cost; higher labor cost |

| Scalability | Easy to scale designs digitally | Scaling requires manual redrawing |

| Flexibility | Quick modifications and version control | Limited flexibility; manual rework needed |

| Storage | Digital files; space-efficient | Physical patterns; requires storage space |

| Learning Curve | Requires software training | Basic pattern skills; intuitive |

Introduction to Pattern Making in Apparel

Digital pattern making in apparel leverages advanced software technologies such as CAD (Computer-Aided Design) to create precise, modifiable garment templates that enhance accuracy and speed. Manual pattern making relies on traditional tools like rulers, curves, and paper to draft patterns, demanding strong technical skill and experience for accurate fabric cutting. Embracing digital pattern making can significantly reduce production time, minimize material waste, and improve consistency in garment design compared to manual techniques.

What is Manual Pattern Making?

Manual pattern making involves creating garment patterns by hand using tools such as rulers, curves, and paper, based on measurements and design sketches. This traditional technique requires skilled craftsmanship to draft, adjust, and perfect patterns for apparel production without relying on digital software. Manual pattern making is essential for bespoke tailoring and small-scale fashion design, offering precise customization and hands-on control over fit and style.

What is Digital Pattern Making?

Digital pattern making is the process of creating clothing patterns using specialized computer software that allows precise measurements and adjustments to be made quickly and efficiently. This technology enables designers to visualize, edit, and replicate patterns with high accuracy, reducing errors and material waste. Digital tools integrate seamlessly with computer-aided manufacturing systems, streamlining production and enhancing scalability in apparel design.

Key Differences: Digital vs Manual Pattern Making

Digital pattern making utilizes computer-aided design (CAD) software to create precise, modifiable templates, significantly reducing production time and errors compared to manual pattern making. Manual pattern making relies on hand-drawing and physical measurements, which can lead to inconsistencies and slower iterations. Digital methods enable seamless integration with automated cutting machines, enhancing efficiency in garment production workflows.

Advantages of Manual Pattern Making

Manual pattern making offers precise control over fabric manipulation, ensuring better fit and custom adjustments tailored to individual body shapes. It enables designers to quickly prototype and make on-the-spot alterations without relying on software, fostering creativity and hands-on craftsmanship. This traditional technique often results in unique, high-quality garments with distinct details that digital methods may overlook.

Benefits of Digital Pattern Making

Digital pattern making enhances precision by utilizing advanced software that reduces human error and ensures consistent measurements across designs. It accelerates the production process through easy modifications and instant previews, saving time compared to manual drafting. Integration with CAD and 3D modeling tools streamlines workflow, enabling seamless collaboration and faster prototyping in the apparel industry.

Cost Comparison: Manual vs Digital Pattern Making

Digital pattern making significantly reduces labor costs by automating complex design processes, while manual pattern making requires extensive skilled craftsmanship, increasing time and expense. Initial investment in digital software and equipment can be higher, but long-term savings emerge from faster production cycles and fewer errors compared to traditional manual methods. Companies adopting digital pattern making report up to 30% cost reduction in pattern development and accelerated time-to-market.

Impact on Production Speed and Efficiency

Digital pattern making accelerates production speed by enabling precise modifications and instant adjustments, reducing errors and material waste. Manual pattern making relies on skilled craftsmanship but demands more time for drafting and revisions, leading to slower turnaround times. Integration of CAD software in digital processes significantly enhances efficiency, streamlining communication between design and manufacturing teams.

Sustainability Considerations in Pattern Making Methods

Digital pattern making reduces fabric waste by enabling precise measurements and virtual adjustments, leading to more sustainable production practices compared to manual methods. It minimizes the need for physical samples, lowering resource consumption and environmental impact in apparel manufacturing. Manual pattern making often results in higher material waste and energy use, making digital techniques a more eco-friendly choice for sustainable fashion.

Choosing the Right Pattern Making Approach for Your Brand

Digital pattern making offers faster revisions, precise measurements, and seamless integration with 3D fitting software, making it ideal for brands prioritizing efficiency and innovation. Manual pattern making provides hands-on customization and tactile control, suitable for artisans and brands emphasizing craftsmanship and unique design elements. Selecting the right pattern making approach depends on your brand's focus on speed, scalability, and the desired balance between technology and traditional expertise.

Digital Pattern Making vs Manual Pattern Making Infographic

productdif.com

productdif.com