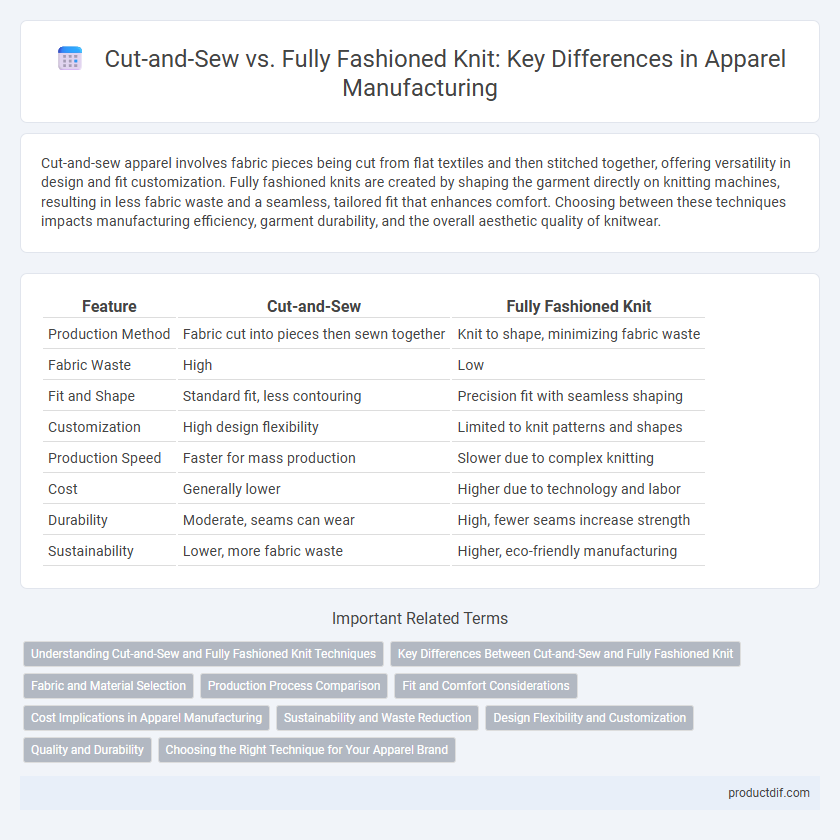

Cut-and-sew apparel involves fabric pieces being cut from flat textiles and then stitched together, offering versatility in design and fit customization. Fully fashioned knits are created by shaping the garment directly on knitting machines, resulting in less fabric waste and a seamless, tailored fit that enhances comfort. Choosing between these techniques impacts manufacturing efficiency, garment durability, and the overall aesthetic quality of knitwear.

Table of Comparison

| Feature | Cut-and-Sew | Fully Fashioned Knit |

|---|---|---|

| Production Method | Fabric cut into pieces then sewn together | Knit to shape, minimizing fabric waste |

| Fabric Waste | High | Low |

| Fit and Shape | Standard fit, less contouring | Precision fit with seamless shaping |

| Customization | High design flexibility | Limited to knit patterns and shapes |

| Production Speed | Faster for mass production | Slower due to complex knitting |

| Cost | Generally lower | Higher due to technology and labor |

| Durability | Moderate, seams can wear | High, fewer seams increase strength |

| Sustainability | Lower, more fabric waste | Higher, eco-friendly manufacturing |

Understanding Cut-and-Sew and Fully Fashioned Knit Techniques

Cut-and-sew involves stitching pre-cut fabric pieces together, allowing diverse material combinations and precise garment shapes, ideal for custom or complex designs. Fully fashioned knit techniques shape garments by knitting fabric panels to exact body contours, minimizing fabric waste and enhancing fit and durability. Both methods impact apparel quality, production efficiency, and garment aesthetics, guiding designers in selecting the optimal construction approach.

Key Differences Between Cut-and-Sew and Fully Fashioned Knit

Cut-and-sew apparel involves cutting fabric pieces and sewing them together, allowing for diverse patterns and fabric combinations, while fully fashioned knit garments are shaped during knitting, minimizing fabric waste and providing a seamless fit. The cut-and-sew method offers greater design flexibility but can result in more seams, whereas fully fashioned knit enhances garment durability and comfort with fewer joins. Understanding these key differences helps apparel manufacturers choose the best technique for product quality, cost-efficiency, and end-use performance.

Fabric and Material Selection

Cut-and-sew apparel utilizes separate fabric pieces tailored to specific garment sections, allowing for diverse fabric types like woven cotton, denim, or jersey blends with precise material control and design flexibility. Fully fashioned knit garments are constructed directly on knitting machines, shaping the fabric to the garment's pattern, often using specialized yarns such as merino wool, cashmere, or high-performance synthetic fibers to enhance stretch, fit, and durability. Fabric selection in fully fashioned knit emphasizes yarn quality and tension consistency, while cut-and-sew demands careful coordination of multiple fabric components for texture and structural integrity.

Production Process Comparison

Cut-and-sew apparel production involves fabric pieces being individually cut and then stitched together, allowing for greater versatility in patterns and fabric combinations. Fully fashioned knit garments are produced by knitting fabric panels to the precise shape of garment pieces, minimizing waste and creating a seamless fit. The cut-and-sew process offers customization and complexity, while fully fashioned knitting emphasizes efficiency and material conservation.

Fit and Comfort Considerations

Cut-and-sew garments offer tailored fit options by assembling separate fabric pieces, allowing precise customization for body contours, while fully fashioned knits provide superior stretch and adaptability through shaping during knitting, enhancing overall comfort. Fit in cut-and-sew apparel depends heavily on pattern accuracy and sewing precision, whereas fully fashioned knitwear inherently accommodates movement and body shape changes due to its seamless construction. Comfort is maximized in fully fashioned knits because of their flexible yarn structure, which reduces pressure points, compared to the potentially stiffer seams in cut-and-sew items.

Cost Implications in Apparel Manufacturing

Cut-and-sew apparel manufacturing typically incurs higher labor costs due to the separate sewing of fabric pieces, whereas fully fashioned knit garments reduce waste by knitting pieces to shape, enhancing material efficiency. Fully fashioned knit production often demands higher initial investment in specialized machinery but results in lower fabric consumption and fewer post-production assembly steps. Cost implications vary significantly as cut-and-sew suits mass production with simpler machinery, while fully fashioned knits optimize costs through precision shaping, offering long-term savings in fabric and labor.

Sustainability and Waste Reduction

Cut-and-sew garments generate significant fabric waste due to pattern cutting, whereas fully fashioned knitwear is shaped during the knitting process, minimizing offcuts and material waste. Fully fashioned techniques reduce energy consumption by eliminating excess manufacturing steps and allow for more efficient use of yarn, contributing to sustainable apparel production. Brands adopting fully fashioned knits benefit from a smaller carbon footprint and align with eco-friendly practices by maximizing fabric utilization.

Design Flexibility and Customization

Cut-and-sew apparel manufacturing offers superior design flexibility by allowing intricate patterns and multiple fabric types to be combined for bespoke customization. Fully fashioned knit production excels in creating seamless garments with precision shaping, enhancing fit and reducing waste but limits fabric variety and complex design integration. Brands prioritizing unique, multi-fabric designs favor cut-and-sew, while those emphasizing precise fit and minimal seaming prefer fully fashioned knitting.

Quality and Durability

Cut-and-sew garments offer superior quality and durability through precise pattern alignment and reinforced stitching that reduces fabric stress points. Fully fashioned knits provide seamless construction with minimal waste but may sacrifice long-term durability due to inherent knit stretch and potential deformation. Choosing cut-and-sew techniques generally results in apparel that withstands wear and maintains shape better over time, appealing to consumers seeking premium, lasting quality.

Choosing the Right Technique for Your Apparel Brand

Choosing between cut-and-sew and fully fashioned knit techniques depends on your brand's design complexity, production volume, and fabric utilization goals. Cut-and-sew is ideal for highly detailed designs and offers flexibility in stitching different fabrics, while fully fashioned knit maximizes material efficiency by shaping garments during knitting, reducing waste and improving fit. Evaluating factors like garment style, sustainability priorities, and cost-effectiveness ensures the right manufacturing method aligns with your apparel brand's identity and market demands.

Cut-and-Sew vs Fully Fashioned Knit Infographic

productdif.com

productdif.com