Pattern grading adjusts existing patterns to create various sizes, ensuring consistent fit across a size range, while pattern making involves designing the original template for a garment. Pattern grading relies on precise measurement increments to scale patterns up or down, whereas pattern making requires creativity and technical skill to conceptualize the garment's shape and details. Understanding both processes is essential for efficient apparel production and achieving high-quality, well-fitting clothing lines.

Table of Comparison

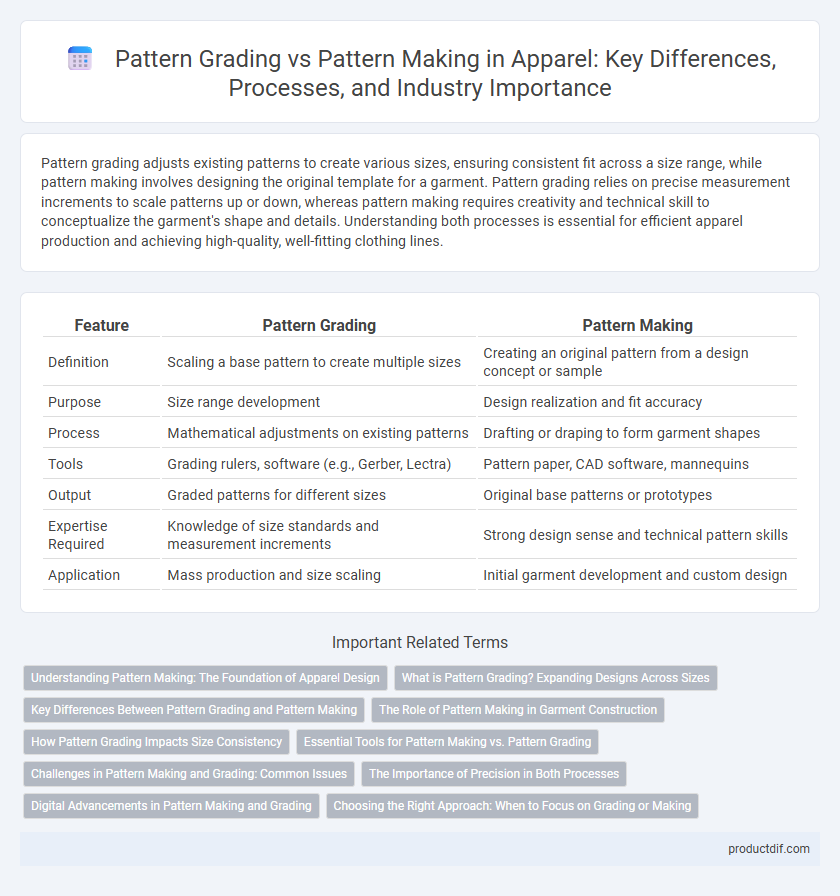

| Feature | Pattern Grading | Pattern Making |

|---|---|---|

| Definition | Scaling a base pattern to create multiple sizes | Creating an original pattern from a design concept or sample |

| Purpose | Size range development | Design realization and fit accuracy |

| Process | Mathematical adjustments on existing patterns | Drafting or draping to form garment shapes |

| Tools | Grading rulers, software (e.g., Gerber, Lectra) | Pattern paper, CAD software, mannequins |

| Output | Graded patterns for different sizes | Original base patterns or prototypes |

| Expertise Required | Knowledge of size standards and measurement increments | Strong design sense and technical pattern skills |

| Application | Mass production and size scaling | Initial garment development and custom design |

Understanding Pattern Making: The Foundation of Apparel Design

Pattern making is the crucial process of translating design sketches into precise templates that guide fabric cutting, shaping the final garment's fit and style. Unlike pattern grading, which adjusts these templates to different sizes, pattern making establishes the original blueprint essential for apparel construction. Mastery of pattern making ensures accuracy in garment dimensions and supports creative expression in fashion design.

What is Pattern Grading? Expanding Designs Across Sizes

Pattern grading is the process of systematically increasing or decreasing the dimensions of a base garment pattern to create a range of sizes, ensuring consistent fit and proportion across all size variations. It involves precise mathematical adjustments to key measurement points such as bust, waist, hips, and length, maintaining the design's intended silhouette and functionality. Unlike pattern making, which develops the original prototype, pattern grading focuses on scaling that prototype accurately for mass production in multiple sizes.

Key Differences Between Pattern Grading and Pattern Making

Pattern grading adjusts existing garment templates to create multiple sizes by scaling measurements proportionally, ensuring consistent fit across size ranges. Pattern making involves the initial creation of garment patterns from design specifications, focusing on the shape, style, and construction details. Key differences include grading's emphasis on size variation and replication, while pattern making centers on original design development and shape creation.

The Role of Pattern Making in Garment Construction

Pattern making serves as the foundation of garment construction by creating precise templates that guide fabric cutting and assembly. Unlike pattern grading, which scales these templates to different sizes, pattern making establishes the original design shape, fit, and structure essential for garment integrity. Accurate pattern making ensures consistent quality and fit, directly impacting the final apparel's appearance and comfort.

How Pattern Grading Impacts Size Consistency

Pattern grading directly influences size consistency by systematically adjusting a base pattern to create a range of sizes while maintaining proportionality and design integrity. Accurate grading ensures that garments fit different body measurements precisely, reducing fit discrepancies across production batches. This process is essential for apparel brands aiming to deliver reliable sizing and enhance customer satisfaction.

Essential Tools for Pattern Making vs. Pattern Grading

Essential tools for pattern making include rulers, French curves, pattern paper, and tracing wheels, which enable precise creation of original garment templates. Pattern grading requires digital grading machines, software like Gerber or Lectra, and measurement charts to accurately scale patterns across sizes. Mastery of both sets of tools ensures efficiency and accuracy in apparel production from design to size variation.

Challenges in Pattern Making and Grading: Common Issues

Pattern making often struggles with maintaining accurate measurements and alignment, leading to inconsistencies in garment fit across different sizes. Pattern grading introduces challenges such as proportion distortion and difficulty preserving design details when scaling patterns up or down. Both processes demand precise technical skills and advanced software to minimize errors and ensure consistent quality in apparel production.

The Importance of Precision in Both Processes

Pattern grading and pattern making are fundamental steps in apparel production where precision directly affects garment fit and quality. Accurate pattern making establishes the original design's proportions, while meticulous pattern grading ensures consistent sizing across different sizes without distortion. Maintaining exact measurements in both processes reduces fabric waste, minimizes production errors, and enhances customer satisfaction with well-fitting clothing.

Digital Advancements in Pattern Making and Grading

Digital advancements in pattern making and grading have revolutionized the apparel industry by enhancing precision and efficiency through software applications like CAD (Computer-Aided Design) systems. These technologies enable automated size grading, reducing manual errors and speeding up the production process while maintaining consistent fit across multiple sizes. Integration of 3D virtual prototyping further streamlines pattern adjustments, allowing designers to visualize garment fit and make modifications before physical samples are created.

Choosing the Right Approach: When to Focus on Grading or Making

Pattern making establishes the original garment blueprint by designing the base shape and dimensions, essential for developing new styles or prototypes. Pattern grading involves systematically resizing these base patterns to create a range of garment sizes while maintaining consistent fit and proportions. Choose pattern making when creating new designs from scratch, and focus on grading to efficiently scale established patterns across size variations.

Pattern grading vs pattern making Infographic

productdif.com

productdif.com