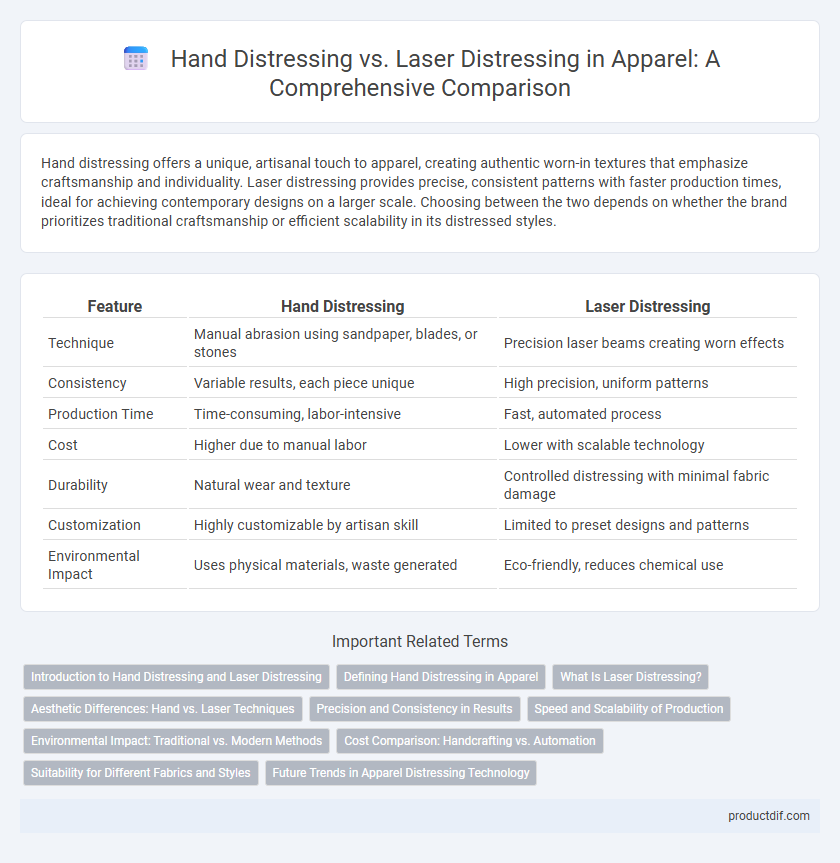

Hand distressing offers a unique, artisanal touch to apparel, creating authentic worn-in textures that emphasize craftsmanship and individuality. Laser distressing provides precise, consistent patterns with faster production times, ideal for achieving contemporary designs on a larger scale. Choosing between the two depends on whether the brand prioritizes traditional craftsmanship or efficient scalability in its distressed styles.

Table of Comparison

| Feature | Hand Distressing | Laser Distressing |

|---|---|---|

| Technique | Manual abrasion using sandpaper, blades, or stones | Precision laser beams creating worn effects |

| Consistency | Variable results, each piece unique | High precision, uniform patterns |

| Production Time | Time-consuming, labor-intensive | Fast, automated process |

| Cost | Higher due to manual labor | Lower with scalable technology |

| Durability | Natural wear and texture | Controlled distressing with minimal fabric damage |

| Customization | Highly customizable by artisan skill | Limited to preset designs and patterns |

| Environmental Impact | Uses physical materials, waste generated | Eco-friendly, reduces chemical use |

Introduction to Hand Distressing and Laser Distressing

Hand distressing in apparel involves manual techniques such as sanding, scraping, and abrasive tools to create a worn, vintage look on fabrics, particularly denim, offering unique texture and character. Laser distressing employs precise, computer-controlled laser beams to replicate natural wear patterns with high accuracy and consistency, enhancing production speed while minimizing fabric damage. Both methods cater to different aesthetic preferences and production demands within the fashion industry.

Defining Hand Distressing in Apparel

Hand distressing in apparel involves manually creating worn or aged effects on fabric using tools like sandpaper, knives, or razors to achieve a unique, artisanal look. This technique allows for precise control over the texture and placement of distress marks, resulting in one-of-a-kind garments with authentic character. Compared to laser distressing, hand distressing offers a more individualized and handcrafted aesthetic favored in premium denim and vintage-style clothing.

What Is Laser Distressing?

Laser distressing is a modern apparel technique that uses precise laser technology to create worn or faded effects on fabrics, especially denim. This method allows for highly controlled, repeatable patterns with minimal environmental impact compared to traditional hand distressing. Brands favor laser distressing for its ability to produce consistent, intricate designs that enhance garment aesthetics while reducing labor and waste.

Aesthetic Differences: Hand vs. Laser Techniques

Hand distressing in apparel creates unique, irregular patterns with a natural, worn-in look that showcases craftsmanship and individuality. Laser distressing offers precise, consistent designs with sharp details, ideal for replicating complex patterns efficiently on a larger scale. The aesthetic differences primarily lie in hand distressing's organic, artisan appeal versus laser distressing's uniform, technology-driven finish.

Precision and Consistency in Results

Hand distressing in apparel offers a unique, artisanal touch with slight variations that enhance garment individuality, while laser distressing provides unparalleled precision and repeatability through computer-controlled technology. Laser techniques ensure consistent patterns and exact placements, ideal for large-scale production demanding uniformity. The choice between hand and laser distressing balances between handcrafted uniqueness and efficient, consistent results in fashion design.

Speed and Scalability of Production

Hand distressing in apparel involves manual techniques that offer unique, artisanal details but require significantly more time and labor, limiting speed and scalability for large production runs. Laser distressing utilizes automated, precision technology to replicate similar worn effects rapidly and consistently, enabling high-speed output and scalable manufacturing processes. Brands seeking efficient mass production with uniform distressed aesthetics often prefer laser distressing over hand methods due to its enhanced speed and scalability.

Environmental Impact: Traditional vs. Modern Methods

Hand distressing in apparel production typically involves abrasive materials and chemical treatments that generate significant waste and pollution, contributing to environmental degradation. Laser distressing uses precise, digital technology that reduces water consumption, chemical use, and hazardous byproducts, offering a cleaner alternative. This modern method supports sustainable fashion by minimizing environmental impact while maintaining desired aesthetic effects.

Cost Comparison: Handcrafting vs. Automation

Hand distressing in apparel offers unique, artisanal finishes but demands significant labor hours, leading to higher per-unit costs compared to laser distressing. Laser distressing utilizes automated technology that enhances precision and speeds up production, reducing overall expenses and consistent output. Brands balancing budget and design complexity often prefer laser distressing for large-scale runs while reserving hand distressing for premium, limited-edition collections.

Suitability for Different Fabrics and Styles

Hand distressing offers a unique, artisanal look best suited for natural fabrics like denim and cotton, allowing for customized wear patterns that complement casual and vintage apparel styles. Laser distressing provides precise, consistent results ideal for delicate or synthetic fabrics such as polyester blends, making it perfect for contemporary designs requiring intricate detailing without compromising fabric integrity. Choosing between these techniques depends on fabric sensitivity and desired style, with hand distressing favoring durability and laser distressing excelling in precision and versatility.

Future Trends in Apparel Distressing Technology

Hand distressing in apparel remains valued for its artisanal, unique finish, but laser distressing gains momentum due to its precision and scalability. Future trends emphasize sustainable, automated laser techniques reducing water and chemical use while offering customizable patterns at high speed. Integration of AI with laser distressing promises hyper-personalized fashion, setting new standards in eco-friendly garment aging processes.

Hand Distressing vs Laser Distressing Infographic

productdif.com

productdif.com