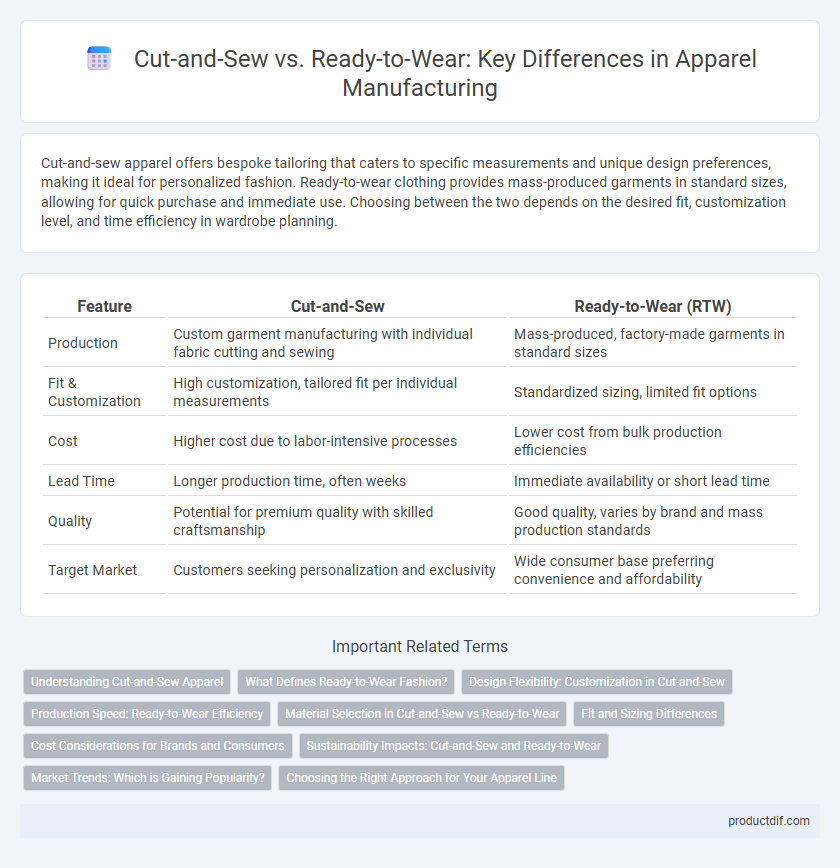

Cut-and-sew apparel offers bespoke tailoring that caters to specific measurements and unique design preferences, making it ideal for personalized fashion. Ready-to-wear clothing provides mass-produced garments in standard sizes, allowing for quick purchase and immediate use. Choosing between the two depends on the desired fit, customization level, and time efficiency in wardrobe planning.

Table of Comparison

| Feature | Cut-and-Sew | Ready-to-Wear (RTW) |

|---|---|---|

| Production | Custom garment manufacturing with individual fabric cutting and sewing | Mass-produced, factory-made garments in standard sizes |

| Fit & Customization | High customization, tailored fit per individual measurements | Standardized sizing, limited fit options |

| Cost | Higher cost due to labor-intensive processes | Lower cost from bulk production efficiencies |

| Lead Time | Longer production time, often weeks | Immediate availability or short lead time |

| Quality | Potential for premium quality with skilled craftsmanship | Good quality, varies by brand and mass production standards |

| Target Market | Customers seeking personalization and exclusivity | Wide consumer base preferring convenience and affordability |

Understanding Cut-and-Sew Apparel

Cut-and-sew apparel involves designing and creating garments from individual fabric pieces, offering customized fits and unique styles unlike mass-produced ready-to-wear clothing. This method allows brands to control quality and fabric choice more precisely, resulting in higher-end, tailored products suitable for niche markets. Apparel manufacturers specializing in cut-and-sew often emphasize craftsmanship and attention to detail to meet specific brand or customer demands.

What Defines Ready-to-Wear Fashion?

Ready-to-wear fashion consists of mass-produced garments available in standardized sizes, designed for immediate purchase and wear without further alterations. These collections are created to appeal to broad consumer markets, emphasizing convenience, affordability, and trend responsiveness. Unlike cut-and-sew, ready-to-wear prioritizes efficient production processes and ready availability over custom fit or individualized design.

Design Flexibility: Customization in Cut-and-Sew

Cut-and-sew garments offer superior design flexibility through extensive customization options, enabling precise tailoring to unique specifications including fabric choice, pattern creation, and detailed finishes. Unlike ready-to-wear clothing, cut-and-sew allows brands and designers to produce limited runs or one-of-a-kind pieces that cater to niche markets or specific customer preferences. This level of customization enhances brand identity and customer satisfaction by delivering personalized apparel that stands apart from mass-produced, standardized items.

Production Speed: Ready-to-Wear Efficiency

Ready-to-wear apparel offers significantly faster production speeds compared to cut-and-sew methods due to standardized sizing and bulk manufacturing processes. Factories utilizing ready-to-wear techniques can produce thousands of garments within days, leveraging automated cutting and sewing technologies. This efficiency is crucial for retailers aiming to quickly respond to market trends and seasonal demands.

Material Selection in Cut-and-Sew vs Ready-to-Wear

Material selection in Cut-and-Sew apparel emphasizes customized fabrics chosen for specific garment designs, often allowing premium textiles and unique blends tailored to the brand's vision. In contrast, Ready-to-Wear collections typically utilize standardized, mass-produced fabrics that balance cost-efficiency with durability, facilitating large-scale production. This fundamental difference impacts the texture, quality, and exclusivity of the final apparel product.

Fit and Sizing Differences

Cut-and-sew apparel offers customized fit and precise sizing tailored to individual body measurements, resulting in superior comfort and a more flattering silhouette. Ready-to-wear garments follow standardized sizing charts, often leading to generalized fits that may not accommodate unique body shapes or proportions. Understanding the fit and sizing distinctions between these two approaches is essential for consumers seeking either personalization or convenience in their clothing choices.

Cost Considerations for Brands and Consumers

Cut-and-sew apparel involves higher production costs due to custom designs, fabric sourcing, and labor-intensive processes, impacting brand pricing strategies and resulting in premium retail prices for consumers. Ready-to-wear garments benefit from economies of scale, standardized sizing, and bulk manufacturing, making them more cost-effective for brands and affordable for a wider consumer base. Brands must balance quality, uniqueness, and market demand when deciding between cut-and-sew and ready-to-wear production to optimize cost-efficiency and customer appeal.

Sustainability Impacts: Cut-and-Sew and Ready-to-Wear

Cut-and-sew apparel production often results in less fabric waste due to customized pattern cutting, enhancing material efficiency and sustainability. Ready-to-wear garments, produced in bulk with standardized sizes, may generate excess inventory and higher waste levels but benefit from economies of scale in resource use. Both methods impact carbon emissions and water consumption, with cut-and-sew enabling more precise sustainable material choices, while ready-to-wear focuses on streamlined mass production and supply chain optimization.

Market Trends: Which is Gaining Popularity?

Cut-and-sew apparel is gaining traction in niche markets due to its customization capabilities and emphasis on sustainable production methods. Ready-to-wear (RTW) maintains dominant market share with mass production efficiency and fast fashion appeal, but recent consumer shift towards personalized, limited-edition clothing is boosting cut-and-sew popularity. Market data from 2023 indicates a 15% annual growth rate for cut-and-sew segments compared to a 5% growth in traditional RTW categories.

Choosing the Right Approach for Your Apparel Line

Selecting between cut-and-sew and ready-to-wear depends on your apparel line's goals, budget, and design complexity. Cut-and-sew offers full customization and quality control, ideal for unique, high-end garments, while ready-to-wear provides faster production and lower costs suited for mass markets. Evaluating production timelines, fabric sourcing, and target audience ensures the right approach enhances brand identity and market success.

Cut-and-Sew vs Ready-to-Wear Infographic

productdif.com

productdif.com