Cut vs sew is a crucial technique in apparel manufacturing that determines the garment's fit and finish. Precise cutting ensures fabric pieces are shaped accurately, while expert sewing joins these pieces seamlessly to create durable, stylish clothing. This process balances efficiency and craftsmanship, impacting the overall quality and comfort of the apparel.

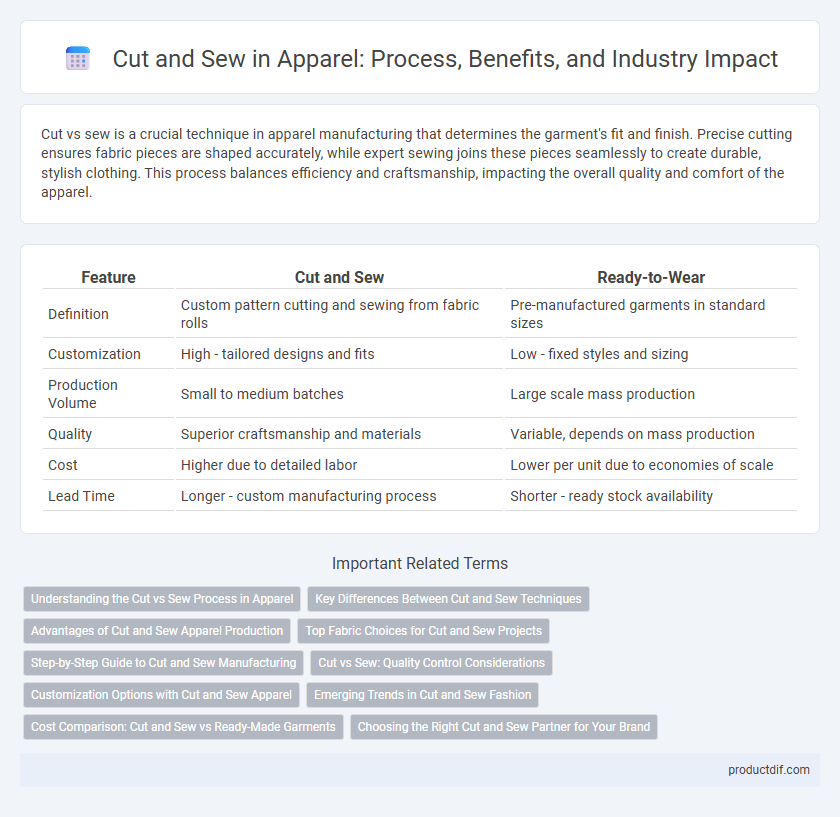

Table of Comparison

| Feature | Cut and Sew | Ready-to-Wear |

|---|---|---|

| Definition | Custom pattern cutting and sewing from fabric rolls | Pre-manufactured garments in standard sizes |

| Customization | High - tailored designs and fits | Low - fixed styles and sizing |

| Production Volume | Small to medium batches | Large scale mass production |

| Quality | Superior craftsmanship and materials | Variable, depends on mass production |

| Cost | Higher due to detailed labor | Lower per unit due to economies of scale |

| Lead Time | Longer - custom manufacturing process | Shorter - ready stock availability |

Understanding the Cut vs Sew Process in Apparel

Cut vs sew in apparel involves two key production methods where cut refers to pre-cut fabric pieces assembled by manufacturers, often for mass production efficiency. Sew encompasses custom garment creation by cutting fabric and sewing each piece individually, allowing for higher precision and unique designs. Understanding the distinction guides better decision-making for quality, scalability, and cost in apparel manufacturing.

Key Differences Between Cut and Sew Techniques

Cut and sew techniques differ primarily in their production processes, where cut and sew involves cutting fabric pieces before stitching them together, allowing for customized garment construction. This method contrasts with fully fashioned techniques that shape garments during knitting or weaving, offering more flexibility in design and fit. Cut and sew apparel ensures precise control over fabric selection and pattern placement, enhancing quality and enabling unique, detailed designs.

Advantages of Cut and Sew Apparel Production

Cut and sew apparel production offers precise customization, enabling brands to create unique designs tailored to specific measurements and styles, enhancing product differentiation. This method ensures superior fabric utilization and construction quality, resulting in durable, well-fitting garments that meet high consumer standards. By leveraging advanced cutting technology and skilled craftsmanship, cut and sew processes minimize material waste and support sustainable manufacturing practices.

Top Fabric Choices for Cut and Sew Projects

Cut and sew projects offer flexibility in using diverse top fabric choices such as cotton, polyester blends, and rayon, which provide a balance of comfort, durability, and ease of customization. Knits and interlocks stand out for their stretch and recovery properties, making them ideal for fitted garments, while woven fabrics like twill and chambray deliver structure and a polished finish. Selecting the appropriate fabric enhances garment performance and aligns with the design vision in cut and sew apparel production.

Step-by-Step Guide to Cut and Sew Manufacturing

Cut and sew manufacturing involves precise steps starting with fabric selection and pattern making, followed by carefully cutting fabric pieces using templates or automated machines to ensure accuracy. Next, skilled sewing operators assemble the cut pieces with industrial sewing machines, focusing on seam strength and garment fit. Quality control checks finalize the process by inspecting stitching, measurements, and overall garment durability before packaging.

Cut vs Sew: Quality Control Considerations

Cut vs sew processes significantly impact apparel quality control by determining the precision and consistency of garment construction. In cut and sew manufacturing, individual fabric pieces are cut and sewn together, allowing stringent inspection at each stage to detect defects such as irregular cuts or stitching errors. Ensuring high-quality outcomes requires meticulous monitoring of fabric alignment, seam strength, and uniformity throughout the cut and sew workflow to meet brand standards and customer expectations.

Customization Options with Cut and Sew Apparel

Cut and sew apparel offers unparalleled customization options by allowing designers to create unique patterns, fabrics, and fits tailored precisely to brand specifications. This method enables intricate detailing such as custom stitching, embroidery, and fabric combinations that mass production cannot achieve. Leveraging cut and sew techniques enhances brand identity through distinctive silhouettes and personalized garment construction.

Emerging Trends in Cut and Sew Fashion

Cut and sew fashion is rapidly evolving with sustainable materials and zero-waste pattern making gaining prominence among designers. Customizable and on-demand production leverages 3D technology to reduce inventory and enhance garment fit precision. Innovative fabric treatments and smart textiles are increasingly integrated to provide functionality alongside style in cut and sew apparel.

Cost Comparison: Cut and Sew vs Ready-Made Garments

Cut and sew garments often incur higher production costs due to factors like custom fabric cutting, sewing labor, and quality control, compared to ready-made garments manufactured in bulk with automated processes. Ready-made garments benefit from economies of scale, significantly reducing per-unit costs, making them a more budget-friendly option for retailers. However, cut and sew offers better customization and unique designs, justifying the premium cost for brands targeting niche markets.

Choosing the Right Cut and Sew Partner for Your Brand

Selecting the ideal cut and sew partner is crucial for apparel brands aiming to ensure precise garment construction and consistent quality control. Evaluate potential manufacturers based on their expertise with specific fabrics, production capacity, and ability to meet your brand's design specifications and delivery timelines. Prioritizing partners with transparent communication, strong industry reputation, and compliance with ethical manufacturing standards enhances overall production efficiency and brand integrity.

Cut vs sew Infographic

productdif.com

productdif.com