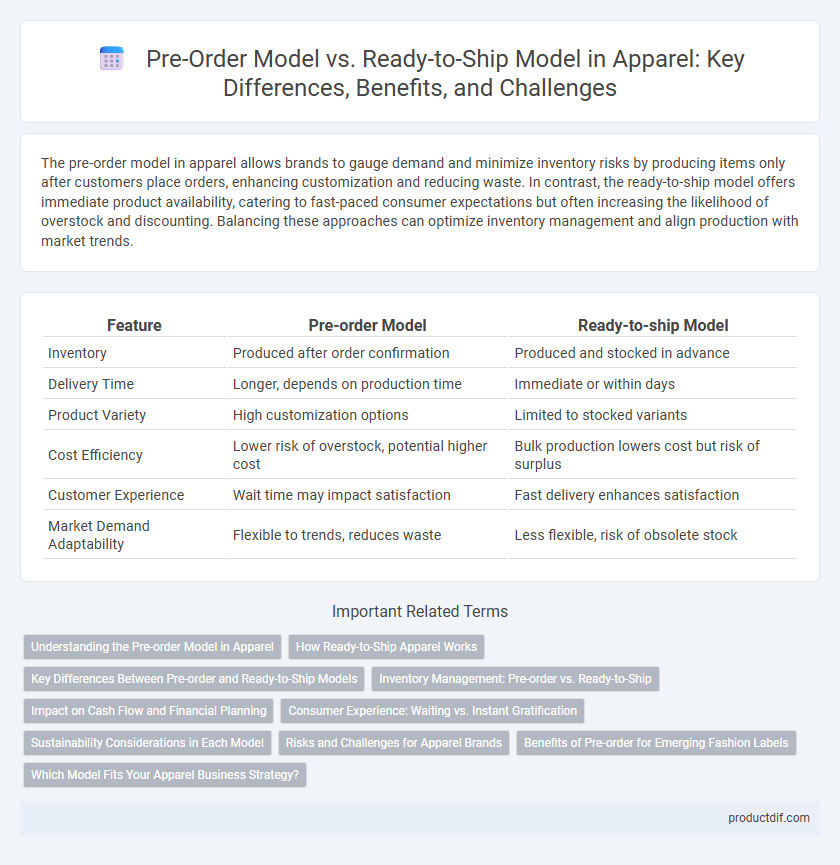

The pre-order model in apparel allows brands to gauge demand and minimize inventory risks by producing items only after customers place orders, enhancing customization and reducing waste. In contrast, the ready-to-ship model offers immediate product availability, catering to fast-paced consumer expectations but often increasing the likelihood of overstock and discounting. Balancing these approaches can optimize inventory management and align production with market trends.

Table of Comparison

| Feature | Pre-order Model | Ready-to-ship Model |

|---|---|---|

| Inventory | Produced after order confirmation | Produced and stocked in advance |

| Delivery Time | Longer, depends on production time | Immediate or within days |

| Product Variety | High customization options | Limited to stocked variants |

| Cost Efficiency | Lower risk of overstock, potential higher cost | Bulk production lowers cost but risk of surplus |

| Customer Experience | Wait time may impact satisfaction | Fast delivery enhances satisfaction |

| Market Demand Adaptability | Flexible to trends, reduces waste | Less flexible, risk of obsolete stock |

Understanding the Pre-order Model in Apparel

The pre-order model in apparel allows brands to produce garments based on consumer demand forecasts, minimizing overproduction and inventory costs while enabling customization and limited edition releases. This model harnesses real-time customer data and trends to optimize supply chain efficiency, reduce waste, and enhance sustainability. Compared to the ready-to-ship model, pre-orders shift production schedules closer to actual sales, fostering a more agile and responsive apparel business strategy.

How Ready-to-Ship Apparel Works

Ready-to-ship apparel involves manufacturing inventory in advance and storing it until customers place orders, ensuring immediate product availability. This model reduces delivery times and caters to spontaneous buyer demands but requires accurate demand forecasting to minimize excess stock. Retailers rely on warehouse logistics and distribution networks to quickly fulfill orders, enhancing customer satisfaction with fast shipping.

Key Differences Between Pre-order and Ready-to-Ship Models

Pre-order models in apparel allow brands to gauge consumer demand and reduce inventory risks by producing items only after orders are received, whereas ready-to-ship models maintain inventory for immediate fulfillment and faster delivery. Pre-order systems often lead to longer lead times but lower overhead costs, while ready-to-ship offers instant availability at the risk of excess stock or markdowns. Operationally, pre-order promotes sustainable production aligned with customer preferences, contrasting with ready-to-ship's focus on quick turnover and retailer stock management.

Inventory Management: Pre-order vs. Ready-to-Ship

Pre-order models in apparel allow brands to produce inventory based on confirmed customer demand, significantly reducing excess stock and minimizing storage costs. In contrast, ready-to-ship models require maintaining larger inventory levels to meet immediate orders, increasing the risk of overstock and markdowns. Effective inventory management in pre-order systems enhances cash flow and sustainability by aligning production closely with sales forecasts, unlike the traditional ready-to-ship approach.

Impact on Cash Flow and Financial Planning

The pre-order model improves cash flow by collecting customer payments before production, reducing inventory costs and minimizing financial risk compared to the ready-to-ship model, which requires upfront investment in stock. This approach enhances financial planning accuracy through better demand forecasting and reduced capital tied in unsold inventory. Ready-to-ship inventory often leads to higher holding costs and potential markdowns, negatively affecting cash reserves and financial stability.

Consumer Experience: Waiting vs. Instant Gratification

The pre-order model in apparel offers consumers unique, customizable options but requires patience as products are typically delivered weeks after purchase. The ready-to-ship model provides immediate availability, catering to customers seeking instant gratification and quick fulfillment. Balancing these models allows brands to address diverse consumer preferences, enhancing overall satisfaction and loyalty.

Sustainability Considerations in Each Model

The pre-order model in apparel reduces waste by producing only what is demanded, minimizing unsold inventory and excess materials. In contrast, the ready-to-ship model often leads to overproduction and higher returns, increasing environmental impact through disposal and transportation emissions. Brands adopting pre-orders contribute to a more sustainable supply chain by aligning production closely with consumer demand and reducing carbon footprint.

Risks and Challenges for Apparel Brands

Pre-order models in apparel carry risks including demand uncertainty, longer cash flow cycles, and inventory misalignment that can lead to stockouts or overproduction. Ready-to-ship models face challenges such as higher upfront inventory costs, potential markdowns on unsold stock, and reliance on accurate sales forecasting to prevent costly excesses. Both models require robust supply chain management and data analytics to mitigate risks and optimize inventory levels for apparel brands.

Benefits of Pre-order for Emerging Fashion Labels

Pre-order models enable emerging fashion labels to minimize inventory risks by producing items only after confirming customer demand, reducing overstock and markdown losses. This approach improves cash flow management by generating upfront payments from customers, allowing brands to reinvest directly into production and marketing efforts. Additionally, pre-orders foster stronger customer engagement and brand loyalty through exclusivity and personalized shopping experiences.

Which Model Fits Your Apparel Business Strategy?

Choosing between the pre-order model and ready-to-ship model depends on your apparel business's inventory management and cash flow strategy. The pre-order model minimizes upfront production costs and reduces overstock risks by manufacturing based on confirmed customer demand. Conversely, the ready-to-ship model ensures immediate product availability, catering to fast-paced consumer markets but requires significant inventory investment and accurate demand forecasting.

Pre-order model vs Ready-to-ship model Infographic

productdif.com

productdif.com