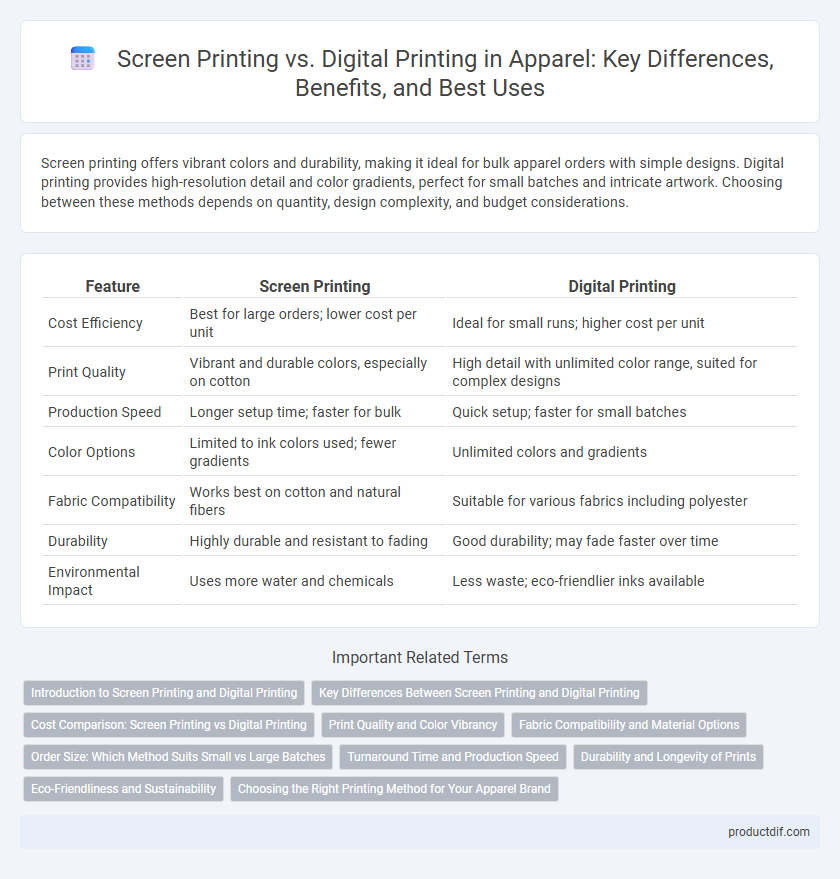

Screen printing offers vibrant colors and durability, making it ideal for bulk apparel orders with simple designs. Digital printing provides high-resolution detail and color gradients, perfect for small batches and intricate artwork. Choosing between these methods depends on quantity, design complexity, and budget considerations.

Table of Comparison

| Feature | Screen Printing | Digital Printing |

|---|---|---|

| Cost Efficiency | Best for large orders; lower cost per unit | Ideal for small runs; higher cost per unit |

| Print Quality | Vibrant and durable colors, especially on cotton | High detail with unlimited color range, suited for complex designs |

| Production Speed | Longer setup time; faster for bulk | Quick setup; faster for small batches |

| Color Options | Limited to ink colors used; fewer gradients | Unlimited colors and gradients |

| Fabric Compatibility | Works best on cotton and natural fibers | Suitable for various fabrics including polyester |

| Durability | Highly durable and resistant to fading | Good durability; may fade faster over time |

| Environmental Impact | Uses more water and chemicals | Less waste; eco-friendlier inks available |

Introduction to Screen Printing and Digital Printing

Screen printing involves applying ink through a mesh stencil onto fabric, creating vibrant and durable designs ideal for bulk apparel production. Digital printing utilizes inkjet technology to print detailed, full-color images directly onto garments, offering greater customization and faster turnaround for small batches. Both methods serve distinct needs in the apparel industry, balancing quality, cost, and production speed.

Key Differences Between Screen Printing and Digital Printing

Screen printing uses stencils and ink layers to create vibrant, durable designs ideal for bulk orders and simple graphics, while digital printing applies inkjet technology for detailed, multicolor images suitable for small runs and custom designs. Screen printing offers exceptional longevity and color intensity on fabrics like cotton, whereas digital printing excels in producing soft, lightweight prints with quick turnaround times. Cost effectiveness varies as screen printing thrives with higher quantities due to setup expenses, whereas digital printing minimizes initial costs for limited quantities or complex artwork.

Cost Comparison: Screen Printing vs Digital Printing

Screen printing typically offers lower costs per unit for large-volume apparel orders due to its setup efficiency and bulk ink usage, making it economically advantageous for mass production. In contrast, digital printing incurs higher initial costs but provides cost-effective solutions for small runs or highly detailed designs without the need for extensive setup. Businesses must evaluate order volume and design complexity to determine the most cost-efficient printing method for their apparel projects.

Print Quality and Color Vibrancy

Screen printing offers superior durability and vibrant colors due to its thick ink layers that create a more vivid and long-lasting print on apparel. Digital printing excels in producing high-resolution, detailed designs with a broader color spectrum, ideal for complex images and gradients. Print quality in screen printing tends to shine on bold, solid colors, while digital printing delivers a sharper finish for intricate patterns and subtle color variations.

Fabric Compatibility and Material Options

Screen printing excels on natural fabrics like cotton, linen, and blends due to its ability to produce vibrant, durable designs that bond well with thick fibers. Digital printing offers greater versatility across diverse fabric types, including polyester, nylon, and silk, allowing for intricate, full-color designs without affecting fabric softness. Both methods present distinct material compatibility, making screen printing ideal for heavyweight textiles and digital printing preferable for lightweight, synthetic fabrics.

Order Size: Which Method Suits Small vs Large Batches

Screen printing excels in large batch orders due to its cost-effectiveness and consistent quality in high-volume production. Digital printing is ideal for small batch orders, offering quick turnaround times and customization without setup costs. Choosing the right method depends on balancing order size, budget, and design complexity for optimal apparel printing results.

Turnaround Time and Production Speed

Screen printing offers faster production speed for large orders due to its high-volume capabilities and efficient ink application process. Digital printing excels in quicker turnaround times for small to medium batches, as it requires minimal setup and allows for on-demand printing. Choosing between these methods depends on order size and the need for rapid delivery in apparel manufacturing.

Durability and Longevity of Prints

Screen printing delivers superior durability and longevity due to its thicker ink layers that penetrate fabric deeply, making prints resistant to fading and cracking over time. Digital printing produces vibrant colors with fine detail but typically has a shorter lifespan, as the thinner ink application is more prone to wear from repeated washing and exposure to elements. For apparel requiring long-lasting designs, screen printing remains the preferred method because of its proven resilience on various fabric types.

Eco-Friendliness and Sustainability

Screen printing uses plastisol inks that contain PVC and phthalates, which pose environmental hazards and require significant water for cleaning, impacting sustainability negatively. Digital printing employs water-based or eco-solvent inks with minimal waste and lower water usage, making it a more environmentally friendly option for apparel customization. Brands seeking sustainable production favor digital printing for its reduced toxic emissions, energy efficiency, and biodegradable ink formulations.

Choosing the Right Printing Method for Your Apparel Brand

Screen printing offers vibrant, durable designs ideal for bulk orders with limited color palettes, while digital printing excels in producing intricate, full-color graphics with quick turnaround times for smaller runs. Selecting the optimal printing method depends on factors such as order volume, design complexity, budget constraints, and fabric type. Apparel brands benefit from evaluating these criteria to ensure high-quality prints that align with their production needs and brand identity.

Screen Printing vs Digital Printing Infographic

productdif.com

productdif.com