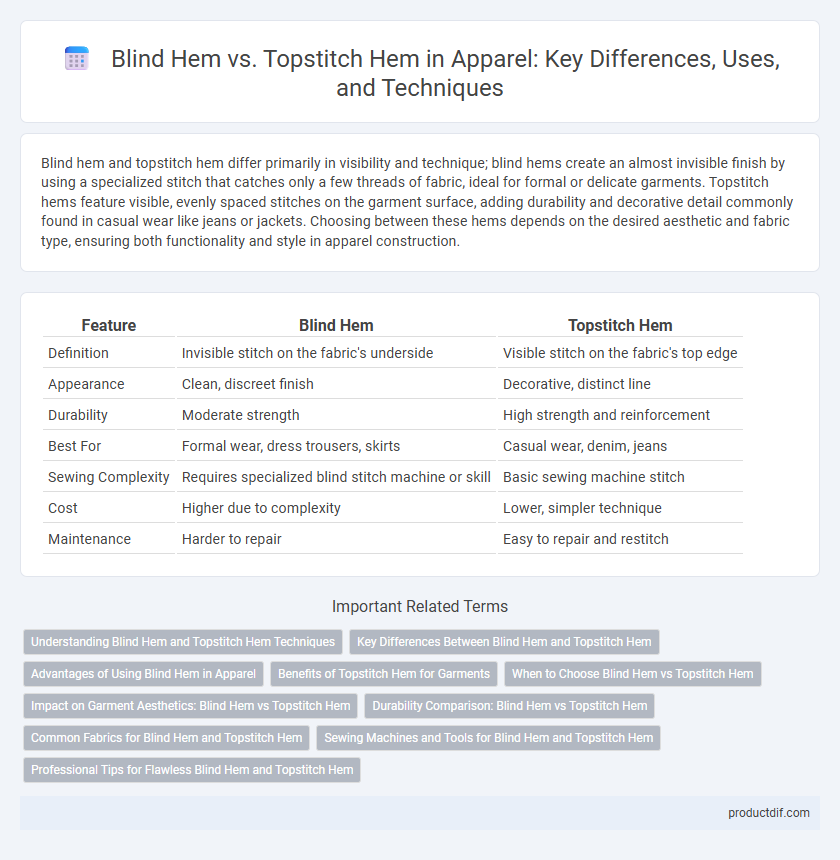

Blind hem and topstitch hem differ primarily in visibility and technique; blind hems create an almost invisible finish by using a specialized stitch that catches only a few threads of fabric, ideal for formal or delicate garments. Topstitch hems feature visible, evenly spaced stitches on the garment surface, adding durability and decorative detail commonly found in casual wear like jeans or jackets. Choosing between these hems depends on the desired aesthetic and fabric type, ensuring both functionality and style in apparel construction.

Table of Comparison

| Feature | Blind Hem | Topstitch Hem |

|---|---|---|

| Definition | Invisible stitch on the fabric's underside | Visible stitch on the fabric's top edge |

| Appearance | Clean, discreet finish | Decorative, distinct line |

| Durability | Moderate strength | High strength and reinforcement |

| Best For | Formal wear, dress trousers, skirts | Casual wear, denim, jeans |

| Sewing Complexity | Requires specialized blind stitch machine or skill | Basic sewing machine stitch |

| Cost | Higher due to complexity | Lower, simpler technique |

| Maintenance | Harder to repair | Easy to repair and restitch |

Understanding Blind Hem and Topstitch Hem Techniques

Blind hem technique involves sewing stitches that are nearly invisible on the garment's right side, achieved by carefully catching only a few threads of fabric during stitching, commonly used for dress pants and skirts to maintain a clean finish. Topstitch hem technique features visible stitches on the garment's surface, providing both decorative and functional reinforcement, often found on denim, casual wear, and outerwear for added durability and style. Choosing between blind hem and topstitch hem depends on the desired aesthetic and garment function, with blind hem preserving a sleek look and topstitch hem enhancing texture and strength.

Key Differences Between Blind Hem and Topstitch Hem

Blind hem features an invisible stitch on the outside of the garment, making it ideal for formal wear and elegant finishes, while topstitch hem displays visible stitching, offering durability and a decorative element often used in casual or denim apparel. The blind hem stitch is secured by small stitches caught on the garment's fabric edge, whereas the topstitch hem uses straight or double rows of stitches sewn on the garment's exterior for added strength. Fabric type and garment style influence the choice, with blind hems preferred for lightweight materials and topstitch hems suited for heavier fabrics requiring reinforcement.

Advantages of Using Blind Hem in Apparel

Blind hem in apparel offers a nearly invisible stitch that enhances garment aesthetics by maintaining a clean, professional finish without visible thread on the fabric's exterior. This hemming technique preserves the garment's design integrity and is ideal for formal wear and delicate fabrics where appearance is critical. Blind hems also provide a flexible seam that allows for natural fabric movement, ensuring comfort and durability in everyday wear.

Benefits of Topstitch Hem for Garments

Topstitch hems provide enhanced durability and a polished finish, making garments more resistant to wear and tear while maintaining a clean, professional appearance. This technique reinforces the hem, reducing the risk of fabric fraying and extending the lifespan of apparel items. The visible stitching also adds a decorative element, allowing designers to incorporate style details that elevate the overall garment aesthetic.

When to Choose Blind Hem vs Topstitch Hem

Blind hems are ideal for formal garments or dress pants where a subtle, nearly invisible finish is desired, maintaining a clean and polished look without visible stitches on the outside. Topstitch hems work best for casual wear, denim, and outerwear, providing durability and a decorative seam that enhances the garment's style and structure. Selecting between blind hem and topstitch hem depends on the fabric type, garment purpose, and the desired balance between aesthetics and functionality.

Impact on Garment Aesthetics: Blind Hem vs Topstitch Hem

Blind hem stitching offers a nearly invisible finish that enhances garment aesthetics by maintaining smooth, uninterrupted fabric surfaces, ideal for formal wear and delicate fabrics. In contrast, topstitch hems provide a visible, decorative seam that adds texture and design detail, often used for casual or structured garments to emphasize seam lines. Choosing between blind hem and topstitch hem impacts both the visual appeal and the overall style statement of the apparel.

Durability Comparison: Blind Hem vs Topstitch Hem

Blind hems create a nearly invisible stitch line by folding fabric edges under, offering moderate durability ideal for lightweight garments but prone to wear in heavy use. Topstitch hems feature visible stitching on the garment's exterior, providing enhanced strength and resistance to frequent washing and abrasion, making them suitable for denim and outerwear. Choosing between blind hem and topstitch hem depends on balancing aesthetic preferences against the required durability for garment type and usage.

Common Fabrics for Blind Hem and Topstitch Hem

Blind hems are commonly used on lightweight to medium-weight fabrics such as cotton blends, wool, silk, and polyester, providing an invisible finish ideal for formalwear and dress pants. Topstitch hems suit heavier fabrics like denim, canvas, and twill, offering durability and a decorative stitch that enhances casual and workwear styles. Both hemming techniques optimize garment performance by matching fabric type with hemming strength and aesthetic requirements.

Sewing Machines and Tools for Blind Hem and Topstitch Hem

Blind hem sewing machines feature specialized feet and settings designed to create nearly invisible stitches by catching only a few threads of the fabric, ideal for hems on dress pants and skirts. Topstitch hem sewing requires machines equipped with straight stitch capabilities and adjustable presser feet to produce visible, reinforced hems often used in denim and casual wear. Using the appropriate sewing machine attachments, such as blind hem feet or topstitch feet, ensures precision and durability in garment finishing.

Professional Tips for Flawless Blind Hem and Topstitch Hem

For a flawless blind hem, use a high-quality blind hem foot and choose thread color that closely matches the fabric to ensure invisibility. When executing a topstitch hem, maintain consistent stitch length and tension for a crisp, professional finish. Press hems with a tailored iron setting to avoid fabric distortion and enhance overall garment durability.

Blind Hem vs Topstitch Hem Infographic

productdif.com

productdif.com