Heat-transfer printing offers vibrant, detailed designs by applying heat to transfer ink onto fabric, making it ideal for small runs and complex images. Screen printing excels in durability and cost-effectiveness for large orders, producing bold, long-lasting prints with fewer color limitations. Choosing between these methods depends on the project's scale, design complexity, and desired fabric feel.

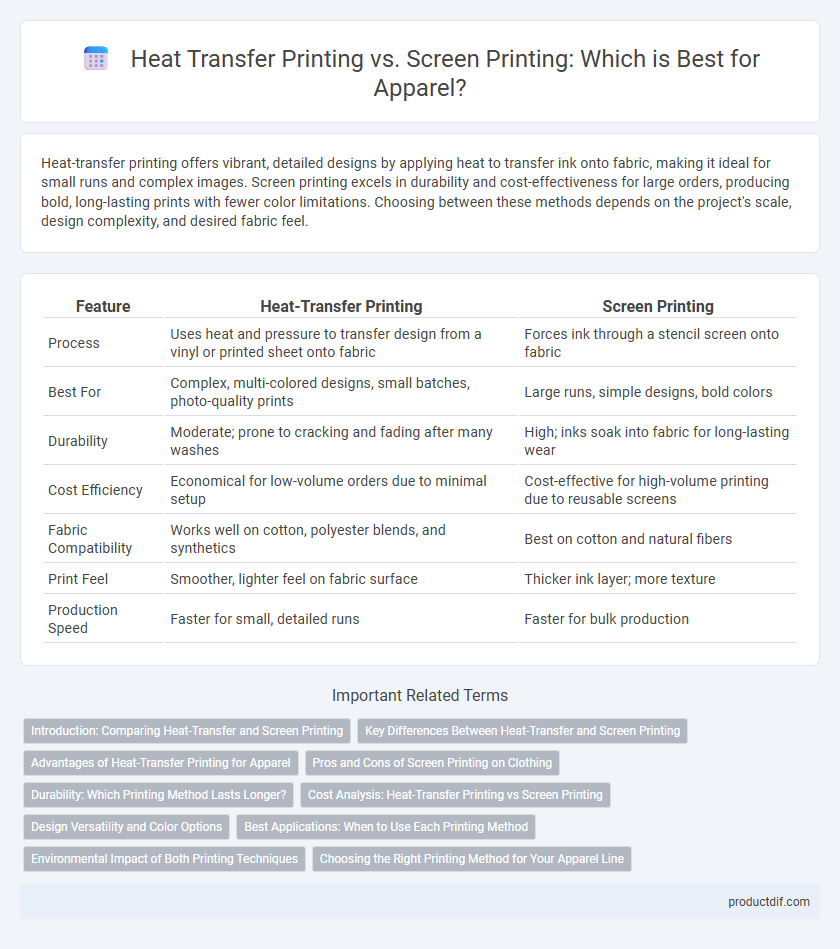

Table of Comparison

| Feature | Heat-Transfer Printing | Screen Printing |

|---|---|---|

| Process | Uses heat and pressure to transfer design from a vinyl or printed sheet onto fabric | Forces ink through a stencil screen onto fabric |

| Best For | Complex, multi-colored designs, small batches, photo-quality prints | Large runs, simple designs, bold colors |

| Durability | Moderate; prone to cracking and fading after many washes | High; inks soak into fabric for long-lasting wear |

| Cost Efficiency | Economical for low-volume orders due to minimal setup | Cost-effective for high-volume printing due to reusable screens |

| Fabric Compatibility | Works well on cotton, polyester blends, and synthetics | Best on cotton and natural fibers |

| Print Feel | Smoother, lighter feel on fabric surface | Thicker ink layer; more texture |

| Production Speed | Faster for small, detailed runs | Faster for bulk production |

Introduction: Comparing Heat-Transfer and Screen Printing

Heat-transfer printing offers vibrant, detailed designs with quick turnaround times, ideal for small batches and complex images on apparel. Screen printing excels in durability and cost-efficiency for large-volume orders, producing bold colors with high opacity on various fabric types. Choice depends on design complexity, order size, and fabric compatibility to achieve optimal print quality and performance.

Key Differences Between Heat-Transfer and Screen Printing

Heat-transfer printing uses heat and pressure to transfer designs from a vinyl or printed film onto fabric, offering vibrant colors and detailed graphics ideal for small runs. Screen printing involves pushing ink through stencils on a mesh screen, producing durable, high-quality images best suited for bulk orders and simple designs. The key differences between heat-transfer and screen printing lie in their cost-effectiveness, design complexity, and production speed, with heat-transfer excelling in customization and screen printing dominating large-scale, cost-efficient production.

Advantages of Heat-Transfer Printing for Apparel

Heat-transfer printing offers superior design versatility, enabling intricate and full-color images that are difficult to achieve with screen printing on apparel. This method provides faster production times and lower setup costs, making it ideal for small batches and custom orders. Heat-transfer printing also ensures vibrant, durable prints with excellent resistance to fading and cracking, enhancing overall garment quality.

Pros and Cons of Screen Printing on Clothing

Screen printing on clothing offers vibrant colors and exceptional durability, making it ideal for bulk orders and designs with few colors. The process provides excellent ink opacity on dark fabrics but can be time-consuming and costly for intricate, multi-colored images. Limitations include less flexibility for small runs and potential environmental concerns due to ink usage and cleanup solvents.

Durability: Which Printing Method Lasts Longer?

Heat-transfer printing offers vibrant colors but tends to fade or crack after extensive washing, reducing its overall durability on apparel. Screen printing uses thick layers of ink that bond deeply with fabric fibers, resulting in superior longevity and resistance to wear over time. For long-lasting apparel designs, screen printing remains the preferred method due to its proven durability and retention of print quality through repeated laundering.

Cost Analysis: Heat-Transfer Printing vs Screen Printing

Heat-transfer printing generally incurs lower initial setup costs compared to screen printing, making it ideal for small batches and customized apparel. Screen printing becomes more cost-effective for large volume orders due to economies of scale and durable ink application. Evaluating order size and design complexity is crucial to optimizing production costs between heat-transfer and screen printing methods.

Design Versatility and Color Options

Heat-transfer printing offers exceptional design versatility by allowing intricate, full-color images with gradients and photographic details, making it ideal for complex and multi-colored designs. Screen printing provides vibrant, durable colors with excellent opacity, especially on darker fabrics, but is best suited for simpler, fewer-color designs due to stencil limitations. Choosing between these methods depends on the balance between design complexity and color fidelity required for the apparel.

Best Applications: When to Use Each Printing Method

Heat-transfer printing excels in producing detailed, multi-colored designs on polyester and synthetic fabrics, making it ideal for short runs, personalized apparel, and sportswear. Screen printing is best suited for large volumes, bold designs, and durable prints on cotton or cotton-blend fabrics, particularly for t-shirts, hoodies, and promotional merchandise. Choosing between these methods depends on fabric type, design complexity, production quantity, and desired print longevity.

Environmental Impact of Both Printing Techniques

Heat-transfer printing generates less water pollution compared to screen printing, which requires large volumes of water for cleaning screens and rinsing excess ink. Screen printing uses plastisol inks containing PVC and phthalates, contributing to toxic waste, whereas heat-transfer utilizes eco-friendly polyurethane inks with fewer harmful chemicals. The energy consumption for heat-transfer printing is typically lower, reducing overall carbon emissions relative to the resource-intensive screen printing process.

Choosing the Right Printing Method for Your Apparel Line

Heat-transfer printing offers vibrant colors and detailed designs ideal for short runs and customization, while screen printing excels in durability and cost-efficiency for larger orders with bold, simple designs. Factors such as fabric type, production volume, and design complexity should guide the choice between these methods to ensure optimal print quality and budget management. Evaluating the longevity requirements and color fidelity of the apparel line helps determine whether heat-transfer or screen printing aligns better with the brand's goals.

Heat-transfer printing vs Screen printing Infographic

productdif.com

productdif.com