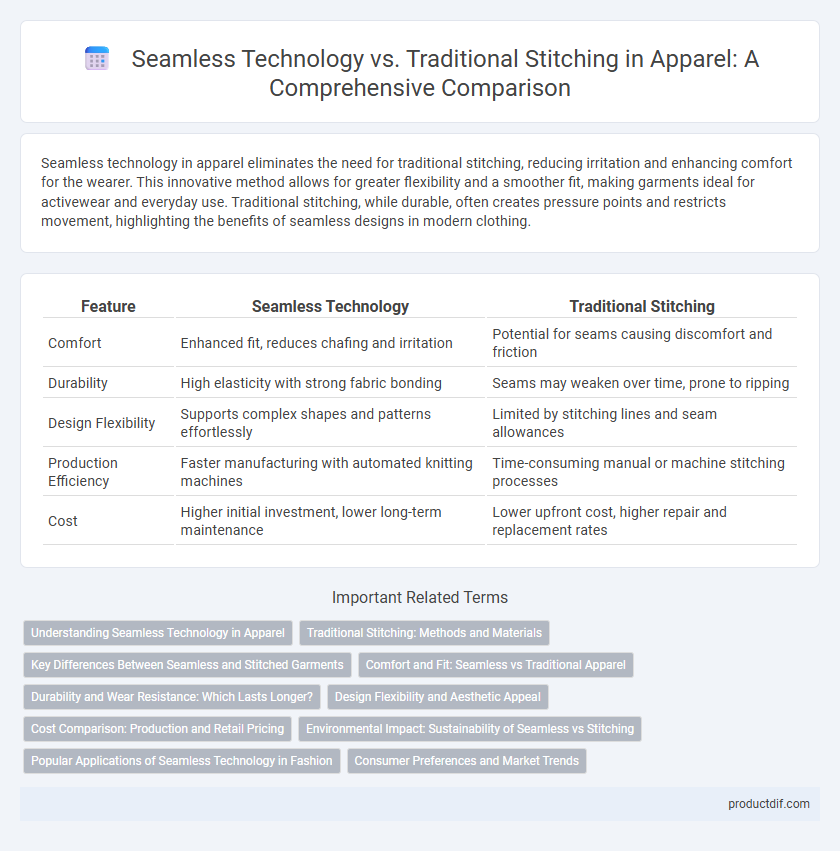

Seamless technology in apparel eliminates the need for traditional stitching, reducing irritation and enhancing comfort for the wearer. This innovative method allows for greater flexibility and a smoother fit, making garments ideal for activewear and everyday use. Traditional stitching, while durable, often creates pressure points and restricts movement, highlighting the benefits of seamless designs in modern clothing.

Table of Comparison

| Feature | Seamless Technology | Traditional Stitching |

|---|---|---|

| Comfort | Enhanced fit, reduces chafing and irritation | Potential for seams causing discomfort and friction |

| Durability | High elasticity with strong fabric bonding | Seams may weaken over time, prone to ripping |

| Design Flexibility | Supports complex shapes and patterns effortlessly | Limited by stitching lines and seam allowances |

| Production Efficiency | Faster manufacturing with automated knitting machines | Time-consuming manual or machine stitching processes |

| Cost | Higher initial investment, lower long-term maintenance | Lower upfront cost, higher repair and replacement rates |

Understanding Seamless Technology in Apparel

Seamless technology in apparel eliminates conventional stitches by using circular knitting machines that create garments in one continuous piece, enhancing comfort and fit. This advanced method reduces chafing and irritation associated with traditional seams, promoting better mobility and moisture management. Brands leveraging seamless construction deliver lightweight, durable clothing optimized for athletic performance and everyday wear.

Traditional Stitching: Methods and Materials

Traditional stitching in apparel primarily utilizes methods such as lockstitch and chainstitch, employing materials like polyester, nylon, and cotton threads to ensure durability and flexibility. The process involves sewing fabric pieces together using sewing machines or hand sewing, allowing for customization in design, reinforcement in high-stress areas, and ease of repair. Traditional stitching supports diverse garment construction techniques, accommodating various fabric types and providing structural integrity through strategically placed seams.

Key Differences Between Seamless and Stitched Garments

Seamless technology creates garments through a single-piece construction using circular knitting machines, resulting in improved flexibility and reduced irritation compared to traditional stitched garments, which are assembled from multiple fabric pieces sewn together. Seamless apparel offers enhanced fit and durability by minimizing seams that can weaken the fabric or cause discomfort during wear. Traditional stitched garments allow for more complex design variations but often sacrifice comfort and may have increased wear points due to visible seam lines.

Comfort and Fit: Seamless vs Traditional Apparel

Seamless technology enhances comfort by eliminating bulky seams, reducing skin irritation and chafing common with traditional stitching. The seamless construction provides a smoother, more adaptive fit that moves naturally with the body, unlike the rigid structure often found in stitched garments. This innovation promotes superior flexibility and breathability, improving overall wearability for active lifestyles.

Durability and Wear Resistance: Which Lasts Longer?

Seamless technology uses advanced knitting methods to create garments without stitches, significantly reducing points of weakness and enhancing durability compared to traditional stitching. Traditional stitching involves seams that can fray or weaken over time, making seamless apparel more resistant to wear and tear under frequent use. Consequently, seamless garments tend to last longer, maintaining structural integrity and appearance despite repeated washing and physical stress.

Design Flexibility and Aesthetic Appeal

Seamless technology offers superior design flexibility by allowing complex, form-fitting shapes without the limitations of stitch lines, enhancing garment comfort and durability. Traditional stitching restricts aesthetic appeal with visible seams that can interrupt sleek silhouettes and limit creative patterns. The smooth finish of seamless apparel promotes a modern, polished look favored in high-performance and fashion-forward clothing.

Cost Comparison: Production and Retail Pricing

Seamless technology reduces labor costs by automating garment construction, leading to lower production expenses compared to traditional stitching, which requires more manual labor and time-consuming processes. This efficiency translates into more competitive retail pricing for seamless apparel, often resulting in better value for consumers without sacrificing quality. Traditional stitched garments typically incur higher production costs that elevate retail prices due to increased material waste and longer assembly times.

Environmental Impact: Sustainability of Seamless vs Stitching

Seamless technology reduces fabric waste by eliminating cut-and-sew processes, significantly lowering material consumption compared to traditional stitching methods that generate offcuts and scrap. This innovation also decreases water and energy usage during production, contributing to a smaller carbon footprint in apparel manufacturing. Brands adopting seamless techniques enhance sustainability by minimizing resource use and promoting eco-friendly garment lifecycle management.

Popular Applications of Seamless Technology in Fashion

Seamless technology revolutionizes apparel production by eliminating stitched seams, providing enhanced comfort and flexibility, especially in activewear and athleisure. Popular applications include sports bras, leggings, and compression garments, where seamless construction reduces chafing and improves fit for high-performance activities. Additionally, seamless technology is widely used in shapewear and lingerie to create smooth silhouettes with minimal visible lines, enhancing both functionality and aesthetic appeal.

Consumer Preferences and Market Trends

Seamless technology in apparel offers enhanced comfort and a superior fit by eliminating stitches that can cause irritation, driving increased consumer demand for seamless garments. Market trends indicate a growing preference for seamless activewear and athleisure, fueled by advancements in knitting techniques and sustainability concerns linked to reduced fabric waste. Traditional stitching remains favored for its durability and aesthetic versatility, but seamless designs are rapidly capturing market share due to innovation and consumer emphasis on comfort and performance.

Seamless technology vs traditional stitching Infographic

productdif.com

productdif.com