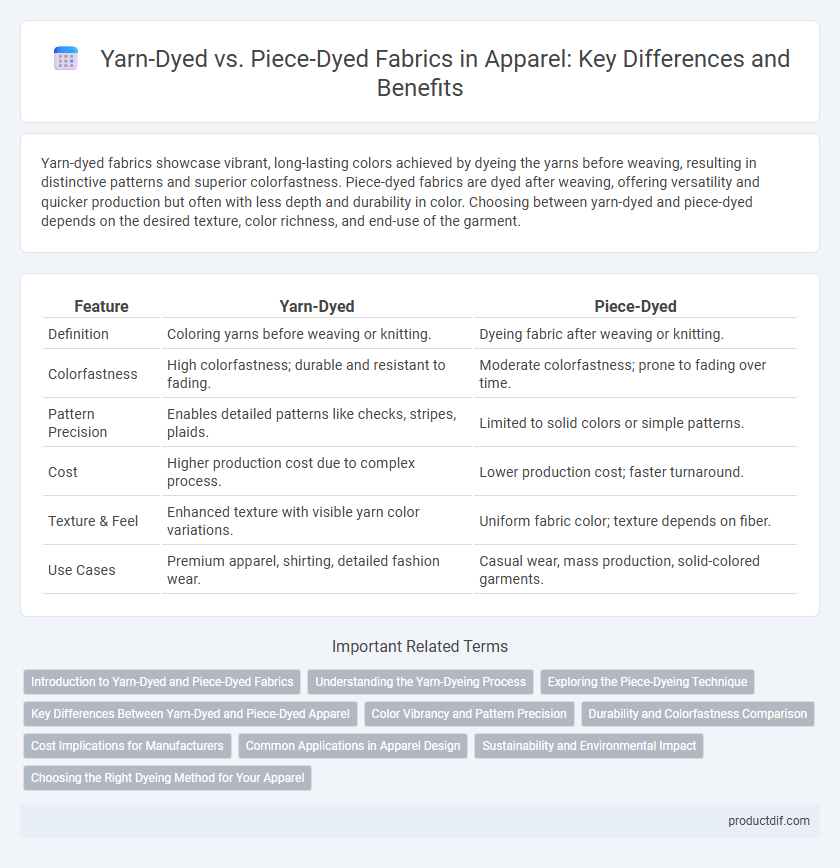

Yarn-dyed fabrics showcase vibrant, long-lasting colors achieved by dyeing the yarns before weaving, resulting in distinctive patterns and superior colorfastness. Piece-dyed fabrics are dyed after weaving, offering versatility and quicker production but often with less depth and durability in color. Choosing between yarn-dyed and piece-dyed depends on the desired texture, color richness, and end-use of the garment.

Table of Comparison

| Feature | Yarn-Dyed | Piece-Dyed |

|---|---|---|

| Definition | Coloring yarns before weaving or knitting. | Dyeing fabric after weaving or knitting. |

| Colorfastness | High colorfastness; durable and resistant to fading. | Moderate colorfastness; prone to fading over time. |

| Pattern Precision | Enables detailed patterns like checks, stripes, plaids. | Limited to solid colors or simple patterns. |

| Cost | Higher production cost due to complex process. | Lower production cost; faster turnaround. |

| Texture & Feel | Enhanced texture with visible yarn color variations. | Uniform fabric color; texture depends on fiber. |

| Use Cases | Premium apparel, shirting, detailed fashion wear. | Casual wear, mass production, solid-colored garments. |

Introduction to Yarn-Dyed and Piece-Dyed Fabrics

Yarn-dyed fabrics are created by dyeing the yarns before weaving, resulting in rich patterns like plaids and stripes with vibrant, long-lasting colors. Piece-dyed fabrics undergo dyeing after the fabric is woven, allowing for uniform color application and cost-effective production suited for solid-colored textiles. Choosing between yarn-dyed and piece-dyed techniques depends on design complexity, durability requirements, and budget constraints.

Understanding the Yarn-Dyeing Process

Yarn-dyeing involves dyeing threads before weaving, which allows for intricate patterns and vibrant, long-lasting colors in apparel. This process ensures color fastness and sharp definition in designs such as plaids and stripes, often used in high-quality shirting fabrics. Understanding yarn-dyeing is crucial for manufacturers aiming to deliver durable and visually distinctive textiles compared to piece-dyed fabrics, where dyeing occurs after weaving.

Exploring the Piece-Dyeing Technique

Piece-dyeing is a versatile textile coloring method where finished fabrics are dyed after weaving, allowing for consistent and uniform color application on various fabric types. This technique enhances fabric softness and drape, making it ideal for apparel that requires a smooth and even color finish. Apparel manufacturers favor piece-dyeing for its cost-effectiveness and flexibility in adapting to color trends without altering yarn inventory.

Key Differences Between Yarn-Dyed and Piece-Dyed Apparel

Yarn-dyed apparel involves dyeing the yarns before weaving, resulting in vibrant, long-lasting patterns with enhanced colorfastness and texture, ideal for plaid and striped fabrics. Piece-dyed apparel is dyed after the fabric is woven, offering greater flexibility in color choices and cost efficiency but with less detailed pattern precision and potentially lower color durability. Key differences include the timing of dye application, impact on fabric appearance, and color longevity, affecting design options and garment quality.

Color Vibrancy and Pattern Precision

Yarn-dyed fabrics exhibit superior color vibrancy and enhanced pattern precision due to the fibers being dyed before weaving, allowing for sharper, more defined designs such as plaids and stripes. Piece-dyed fabrics, dyed after weaving, often have less intense colors and less accurate pattern definition, making them better suited for solid colors or simpler patterns. Brands seeking long-lasting, vivid textiles with intricate designs typically prefer yarn-dyed methods to achieve premium quality apparel.

Durability and Colorfastness Comparison

Yarn-dyed fabrics offer superior durability and colorfastness compared to piece-dyed materials due to the color being embedded in the fiber before weaving, which reduces fading and wear over time. Piece-dyed fabrics often experience quicker color loss and decreased fabric strength since the dye penetrates only the surface after weaving, making them more susceptible to washing and abrasion. Choosing yarn-dyed apparel ensures longer-lasting vibrancy and resilience, ideal for garments requiring frequent use and cleaning.

Cost Implications for Manufacturers

Yarn-dyed fabrics generally incur higher production costs due to intricate dyeing processes applied before weaving, resulting in greater labor and material expenses. Piece-dyed fabrics offer cost savings by dyeing entire fabric rolls after weaving, streamlining manufacturing and allowing bulk processing. Manufacturers weigh these cost implications against quality requirements and design complexity to optimize production budgets and market positioning.

Common Applications in Apparel Design

Yarn-dyed fabrics are commonly used in apparel designs requiring intricate patterns such as plaids, stripes, and checks, benefiting from colorfastness and sharp definition due to dyeing yarns before weaving. Piece-dyed fabrics are preferred for solid-colored garments, providing flexibility in color choice and faster production for casual wear, T-shirts, and sportswear. Both dyeing methods influence texture and durability, with yarn-dyed offering more depth in color and piece-dyed suited for versatile, quick-turnaround apparel collections.

Sustainability and Environmental Impact

Yarn-dyed fabrics significantly reduce environmental impact by minimizing water consumption and chemical use during the dyeing process, as colors are applied directly to the yarn before weaving. In contrast, piece-dyed textiles require large volumes of water and energy to dye finished fabric, leading to increased pollution and resource depletion. Choosing yarn-dyed options supports sustainable apparel practices by promoting durability and reducing the carbon footprint throughout production.

Choosing the Right Dyeing Method for Your Apparel

Yarn-dyed fabrics offer vibrant, long-lasting colors and intricate patterns, making them ideal for high-quality apparel requiring durability and colorfastness. Piece-dyed fabrics provide flexibility and cost-effectiveness, suitable for solid-colored garments or quick production cycles in the fashion industry. Selecting the appropriate dyeing method depends on the design complexity, budget constraints, and desired fabric performance for your apparel line.

Yarn-Dyed vs Piece-Dyed Infographic

productdif.com

productdif.com