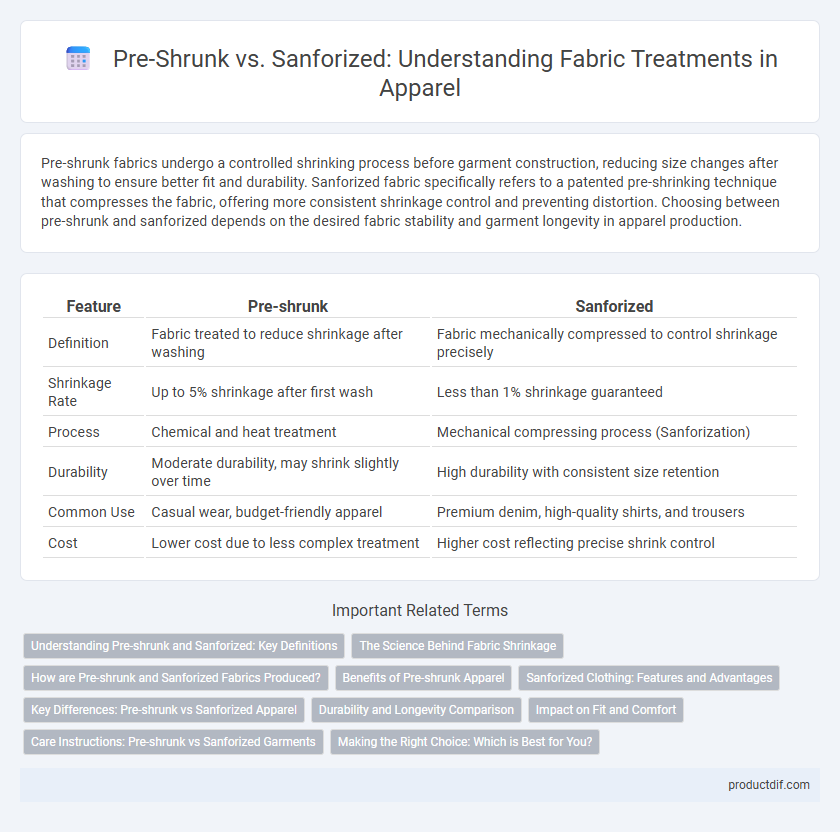

Pre-shrunk fabrics undergo a controlled shrinking process before garment construction, reducing size changes after washing to ensure better fit and durability. Sanforized fabric specifically refers to a patented pre-shrinking technique that compresses the fabric, offering more consistent shrinkage control and preventing distortion. Choosing between pre-shrunk and sanforized depends on the desired fabric stability and garment longevity in apparel production.

Table of Comparison

| Feature | Pre-shrunk | Sanforized |

|---|---|---|

| Definition | Fabric treated to reduce shrinkage after washing | Fabric mechanically compressed to control shrinkage precisely |

| Shrinkage Rate | Up to 5% shrinkage after first wash | Less than 1% shrinkage guaranteed |

| Process | Chemical and heat treatment | Mechanical compressing process (Sanforization) |

| Durability | Moderate durability, may shrink slightly over time | High durability with consistent size retention |

| Common Use | Casual wear, budget-friendly apparel | Premium denim, high-quality shirts, and trousers |

| Cost | Lower cost due to less complex treatment | Higher cost reflecting precise shrink control |

Understanding Pre-shrunk and Sanforized: Key Definitions

Pre-shrunk fabric undergoes a controlled washing process to reduce shrinkage after initial manufacturing, ensuring garments maintain their size with minimal distortion after washing. Sanforized fabric is treated through a mechanical process that compresses the fibers, effectively pre-shrinking the material permanently before cutting and sewing, guaranteeing less than 1% shrinkage. Both processes enhance apparel quality by offering stability in fit and sizing, but Sanforization typically provides stronger assurance of minimal shrinkage compared to pre-shrinking alone.

The Science Behind Fabric Shrinkage

Pre-shrunk fabrics undergo controlled heat treatment to stabilize fibers, preventing significant shrinkage after washing, while Sanforized fabrics are mechanically compressed through a process involving steam and pressure to restrict dimensional changes. Both techniques leverage thermal and mechanical manipulation to alter fabric tension, ensuring garment longevity and fit retention. Understanding these scientific principles helps manufacturers deliver consistent apparel sizing and enhances consumer satisfaction.

How are Pre-shrunk and Sanforized Fabrics Produced?

Pre-shrunk fabrics undergo controlled washing and drying processes to minimize future shrinkage by relaxing fibers before garment construction. Sanforized fabrics are produced through a mechanical stretching technique followed by heat application, ensuring dimensional stability and nearly eliminating shrinkage. Both methods enhance fabric durability and fit retention, making them essential treatments in apparel manufacturing.

Benefits of Pre-shrunk Apparel

Pre-shrunk apparel offers the benefit of maintaining its original size and fit after washing, reducing the risk of unexpected shrinkage that can distort garment dimensions. This process enhances fabric stability and comfort, ensuring consistent wearability and longevity over multiple wash cycles. Consumers appreciate pre-shrunk clothing for its reliable sizing, which simplifies purchasing decisions and improves overall satisfaction.

Sanforized Clothing: Features and Advantages

Sanforized clothing undergoes a controlled compressive shrinkage process, ensuring fabric stability and consistent fit after washing. This treatment minimizes post-purchase shrinkage to less than 1%, enhancing garment durability and consumer satisfaction. The Sanforization method also maintains fabric softness and color retention, making it ideal for high-quality apparel production.

Key Differences: Pre-shrunk vs Sanforized Apparel

Pre-shrunk apparel undergoes a controlled washing process to minimize fabric shrinkage after manufacturing, ensuring that the garment maintains its size and fit over time. Sanforized apparel goes through a mechanical stretching and fixing treatment called Sanforization, which stabilizes the fibers and significantly reduces post-purchase shrinkage to less than 1%. The key difference lies in the method and effectiveness of shrinkage control, with Sanforized garments typically offering more precise dimensional stability compared to general pre-shrinking techniques.

Durability and Longevity Comparison

Pre-shrunk apparel undergoes a process to minimize shrinkage after washing, enhancing garment fit retention but offering moderate durability against fabric wear. Sanforized fabrics are mechanically treated to control shrinkage and significantly improve fabric strength, resulting in longer-lasting garments with superior resistance to deformation. Choosing sanforized apparel typically ensures greater longevity and sustained durability compared to standard pre-shrunk options.

Impact on Fit and Comfort

Pre-shrunk fabrics undergo controlled shrinkage before garment construction, ensuring consistent fit and reducing post-wash size changes, which enhances long-term comfort. Sanforized textiles experience mechanical treatment to limit shrinkage to less than 1%, providing a stable fit without compromising fabric softness or breathability. Both processes improve garment durability and wearer comfort by maintaining shape retention and minimizing fabric distortion during laundering.

Care Instructions: Pre-shrunk vs Sanforized Garments

Pre-shrunk garments typically require minimal shrinkage care, allowing for machine washing in cold water and tumble drying on low without significant size alteration. Sanforized fabrics undergo a controlled shrinking process, reducing post-wash deformation but still benefit from gentle washing and low-heat drying to maintain fabric integrity. Proper care for both pre-shrunk and sanforized apparel ensures consistent fit and prolongs garment lifespan by minimizing fabric stress and distortion.

Making the Right Choice: Which is Best for You?

Choosing between pre-shrunk and Sanforized apparel depends on your priority for fabric stability and long-term wear. Pre-shrunk garments undergo a washing process to minimize shrinkage after purchase, offering consistent fit immediately, while Sanforized fabrics are mechanically treated to prevent shrinkage and maintain shape through multiple washes. Opt for pre-shrunk apparel for ready-to-wear convenience, whereas Sanforized is ideal for high-quality durability and maintaining garment dimensions over time.

Pre-shrunk vs Sanforized Infographic

productdif.com

productdif.com