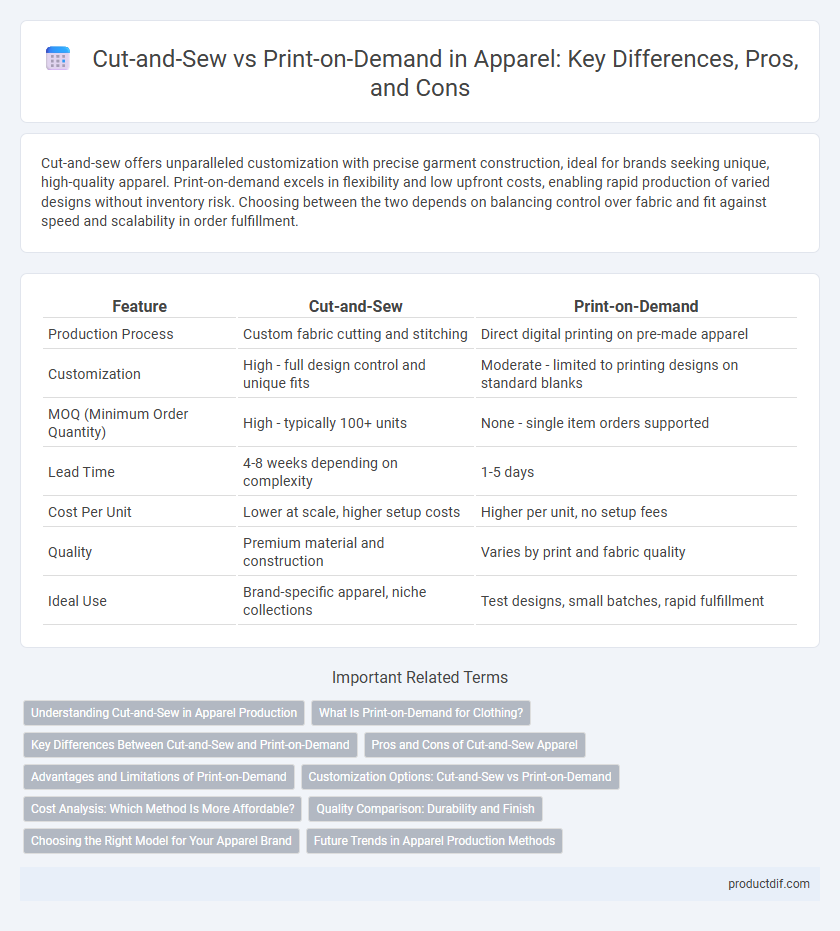

Cut-and-sew offers unparalleled customization with precise garment construction, ideal for brands seeking unique, high-quality apparel. Print-on-demand excels in flexibility and low upfront costs, enabling rapid production of varied designs without inventory risk. Choosing between the two depends on balancing control over fabric and fit against speed and scalability in order fulfillment.

Table of Comparison

| Feature | Cut-and-Sew | Print-on-Demand |

|---|---|---|

| Production Process | Custom fabric cutting and stitching | Direct digital printing on pre-made apparel |

| Customization | High - full design control and unique fits | Moderate - limited to printing designs on standard blanks |

| MOQ (Minimum Order Quantity) | High - typically 100+ units | None - single item orders supported |

| Lead Time | 4-8 weeks depending on complexity | 1-5 days |

| Cost Per Unit | Lower at scale, higher setup costs | Higher per unit, no setup fees |

| Quality | Premium material and construction | Varies by print and fabric quality |

| Ideal Use | Brand-specific apparel, niche collections | Test designs, small batches, rapid fulfillment |

Understanding Cut-and-Sew in Apparel Production

Cut-and-sew apparel production involves creating garments from scratch by cutting fabric pieces and sewing them together, ensuring higher customization and premium quality compared to print-on-demand. This method allows for precise control over fabric selection, stitching techniques, and garment fit, resulting in durable and tailored clothing. Brands often choose cut-and-sew for collections requiring unique design elements, structural complexity, and elevated production standards.

What Is Print-on-Demand for Clothing?

Print-on-demand for clothing is a fulfillment method where custom apparel designs are printed directly onto garments only after an order is placed, eliminating the need for inventory storage. This process leverages digital printing technology to apply images or text onto fabrics such as cotton, polyester, or blends with precision and durability. Print-on-demand offers flexibility for startups and small businesses to test designs, reduce upfront costs, and quickly respond to market trends without traditional manufacturing constraints.

Key Differences Between Cut-and-Sew and Print-on-Demand

Cut-and-sew apparel involves custom garment construction from fabric, allowing tailored fits and detailed designs, while print-on-demand relies on printing directly onto pre-made garments, offering faster production but limited customization. Cut-and-sew supports higher-quality materials and complex patterns, ideal for premium or niche markets, whereas print-on-demand excels in low-volume runs and quick design changes. Key differences include production time, cost efficiency, design flexibility, and garment quality, influencing brand strategy and customer experience.

Pros and Cons of Cut-and-Sew Apparel

Cut-and-sew apparel offers unparalleled customization with precise fabric selection, tailored fit, and intricate design control, ideal for high-quality, unique garments. Production involves higher initial costs, longer lead times, and minimum order quantities, making it less flexible for rapid market testing compared to print-on-demand. The durability and premium feel of cut-and-sew products often justify the investment for brands prioritizing long-term customer satisfaction and brand differentiation.

Advantages and Limitations of Print-on-Demand

Print-on-demand offers low upfront costs and eliminates inventory risks, making it ideal for small businesses and customizable apparel. However, it usually comes with higher per-unit costs and longer production times compared to cut-and-sew methods. Limitations include restricted fabric choices and less control over fit and quality customization.

Customization Options: Cut-and-Sew vs Print-on-Demand

Cut-and-sew apparel offers unparalleled customization options by allowing precise control over fabric selection, pattern design, and garment construction, enabling brand differentiation through unique fits and finishes. Print-on-demand primarily customizes designs through digital printing on pre-made garments, limiting alterations to visual elements without modifying fabric type or garment structure. Brands seeking extensive personalization in both aesthetics and garment architecture benefit more from cut-and-sew, while print-on-demand suits fast, design-flexible applications on standardized apparel.

Cost Analysis: Which Method Is More Affordable?

Cost analysis reveals that cut-and-sew apparel typically demands higher upfront investment due to material sourcing, labor, and manufacturing, while print-on-demand minimizes initial expenses by producing items only after orders are placed, eliminating inventory risks. Print-on-demand excels in affordability for small batches and customization, whereas cut-and-sew becomes more cost-effective with large volume orders because of economies of scale. Businesses seeking budget-friendly options often prefer print-on-demand for its low-risk model, whereas brands focused on premium quality and bulk production favor cut-and-sew despite the higher initial costs.

Quality Comparison: Durability and Finish

Cut-and-sew apparel offers superior durability and a premium finish due to precise stitching and customized fabric selection, ensuring garments maintain shape and quality after multiple washes. Print-on-demand products often use digital printing directly on blanks, resulting in quicker production but potential fading and less robust fabric integration over time. Investing in cut-and-sew methods guarantees higher-quality apparel with enhanced longevity and refined detailing compared to standard print-on-demand options.

Choosing the Right Model for Your Apparel Brand

Cut-and-sew apparel offers complete customization with control over fabric, fit, and construction, ideal for brands prioritizing unique design and quality. Print-on-demand allows rapid production with minimal upfront investment, making it suitable for testing new designs or targeting diverse markets without inventory risk. Selecting the right model depends on your brand's scale, budget, and design flexibility requirements.

Future Trends in Apparel Production Methods

Cut-and-sew methods in apparel production offer precise craftsmanship and customization, maintaining strong relevance for high-quality garments in future markets. Print-on-demand technology accelerates production speed and reduces inventory costs, aligning with sustainability goals and just-in-time manufacturing trends. Advances in digital printing and fabric innovation will drive print-on-demand adoption, while hybrid models integrating cut-and-sew and digital techniques are set to reshape apparel production landscapes.

Cut-and-sew vs Print-on-demand Infographic

productdif.com

productdif.com