Taped seams provide enhanced water resistance and durability by sealing stitch holes with waterproof tape, making them ideal for outdoor and performance apparel. Welded seams use heat and pressure to fuse fabric edges together, offering a sleek, lightweight finish without adding bulk or compromising breathability. Both techniques improve garment longevity, but taped seams excel in waterproof protection while welded seams prioritize minimal weight and a streamlined look.

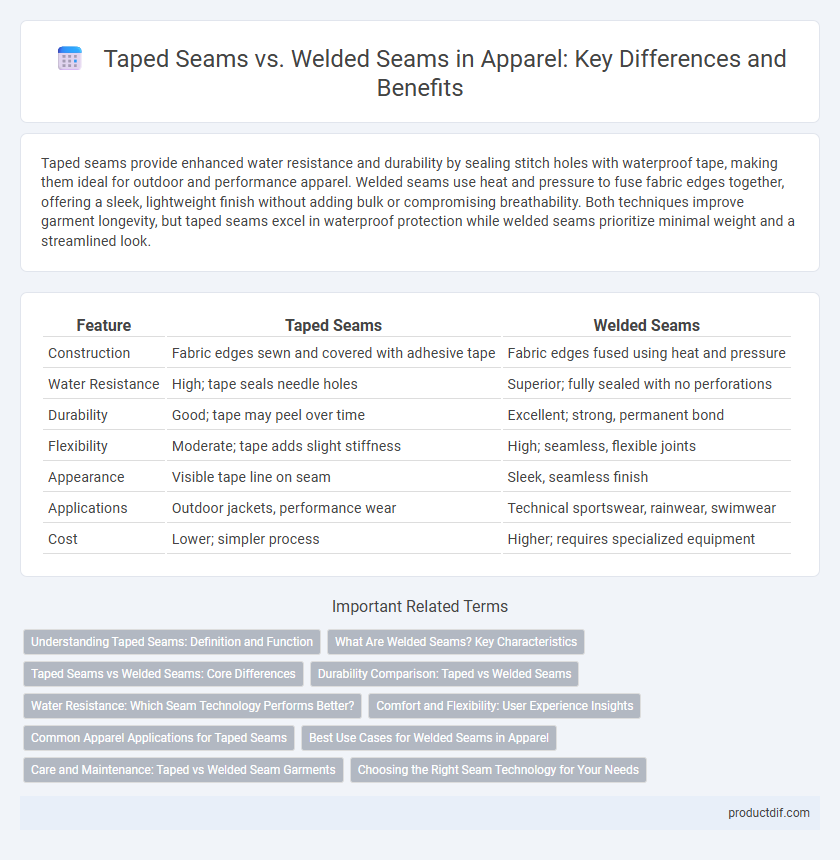

Table of Comparison

| Feature | Taped Seams | Welded Seams |

|---|---|---|

| Construction | Fabric edges sewn and covered with adhesive tape | Fabric edges fused using heat and pressure |

| Water Resistance | High; tape seals needle holes | Superior; fully sealed with no perforations |

| Durability | Good; tape may peel over time | Excellent; strong, permanent bond |

| Flexibility | Moderate; tape adds slight stiffness | High; seamless, flexible joints |

| Appearance | Visible tape line on seam | Sleek, seamless finish |

| Applications | Outdoor jackets, performance wear | Technical sportswear, rainwear, swimwear |

| Cost | Lower; simpler process | Higher; requires specialized equipment |

Understanding Taped Seams: Definition and Function

Taped seams involve sewing fabric panels together and applying a waterproof tape over the stitch line to prevent water penetration while maintaining flexibility. This method enhances garment durability and waterproof performance, especially in outdoor apparel like rain jackets and sportswear. Understanding taped seams is essential for assessing the balance between breathability and weather resistance in technical garments.

What Are Welded Seams? Key Characteristics

Welded seams in apparel are created by fusing fabric edges using heat and pressure, resulting in a smooth, waterproof, and flexible joint without stitching holes. This technique enhances durability and minimizes water penetration, making it ideal for performance outerwear and activewear. Welded seams contribute to lightweight designs and maintain fabric integrity better than traditional sewn seams.

Taped Seams vs Welded Seams: Core Differences

Taped seams involve the application of adhesive tape over stitched fabric to enhance water resistance, commonly used in outdoor and performance apparel for increased durability and comfort. Welded seams eliminate needle holes by fusing fabric edges together using heat or ultrasonic technology, offering superior waterproofing and a sleek, lightweight finish ideal for technical garments. The core differences lie in taped seams relying on traditional stitching reinforced for moisture protection, while welded seams create seamless bonds that provide enhanced water and wind resistance with a cleaner appearance.

Durability Comparison: Taped vs Welded Seams

Taped seams use a fabric strip and adhesive to cover stitched seams, providing flexibility and water resistance, while welded seams fuse fabric edges using heat and pressure, creating a stronger, more durable bond. Welded seams typically outperform taped seams in durability, especially under frequent stress and washing, as they eliminate needle holes that can weaken the fabric. Apparel designed for intense outdoor or athletic activities often favors welded seams for enhanced longevity and performance.

Water Resistance: Which Seam Technology Performs Better?

Taped seams provide superior water resistance by covering stitch holes with waterproof tape, preventing water penetration effectively in outdoor and performance apparel. Welded seams use heat and pressure to fuse fabric edges, creating a smooth, waterproof barrier that is highly durable but may be less flexible compared to taped seams. For optimal water resistance, taped seams typically outperform welded seams in preventing water seepage under high-moisture conditions.

Comfort and Flexibility: User Experience Insights

Taped seams provide enhanced water resistance and durability but may sometimes cause slight stiffness, affecting overall comfort and flexibility in active wear. Welded seams offer a smoother, more flexible finish that reduces irritation and allows for greater movement, making them ideal for performance apparel where stretch and comfort are crucial. User feedback often highlights welded seams as the preferred choice for prolonged comfort due to their seamless construction and breathability.

Common Apparel Applications for Taped Seams

Taped seams are widely used in waterproof and activewear apparel to enhance durability and prevent water penetration by sealing stitch holes. Common applications include rain jackets, outdoor gear, sportswear, and technical garments where moisture resistance and longevity are critical. This method ensures enhanced protection and comfort for wearers in wet or harsh environments.

Best Use Cases for Welded Seams in Apparel

Welded seams in apparel provide superior waterproofing and durability, making them ideal for performance outerwear, activewear, and technical gear exposed to harsh weather conditions. These seams eliminate needle holes, enhancing garment integrity and preventing water ingress, which is crucial for rain jackets, ski wear, and cycling apparel. The smooth, flexible finish of welded seams also enhances comfort and reduces chafing in high-movement areas, optimizing wearability in sports and outdoor clothing.

Care and Maintenance: Taped vs Welded Seam Garments

Taped seams require gentle washing in cold water to preserve the adhesive tape and prevent peeling, making low-heat drying or air-drying essential for longevity. Welded seam garments offer enhanced durability with water-resistant bonding that withstands frequent washing and higher temperatures without compromising seam integrity. Regular inspection of taped seams is recommended to catch early signs of wear, while welded seams typically demand less maintenance due to their stronger, heat-fused construction.

Choosing the Right Seam Technology for Your Needs

Taped seams provide superior waterproofing by sealing stitch holes, making them ideal for outdoor apparel and rainwear, whereas welded seams join fabric layers without stitching, offering enhanced durability and a sleek finish suited for activewear and performance gear. Selecting the right seam technology depends on durability requirements, fabric type, and intended garment use; taped seams are best for maximum water resistance, while welded seams are preferred for minimizing bulk and increasing flexibility. Evaluating these factors ensures optimal protection, comfort, and longevity in your apparel design.

Taped Seams vs Welded Seams Infographic

productdif.com

productdif.com