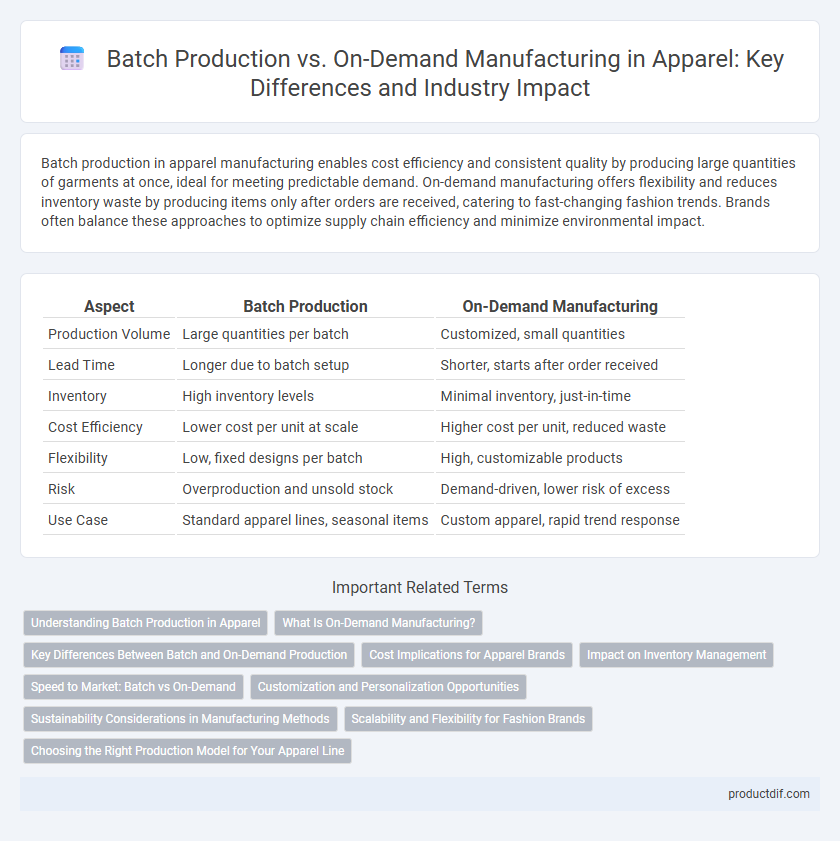

Batch production in apparel manufacturing enables cost efficiency and consistent quality by producing large quantities of garments at once, ideal for meeting predictable demand. On-demand manufacturing offers flexibility and reduces inventory waste by producing items only after orders are received, catering to fast-changing fashion trends. Brands often balance these approaches to optimize supply chain efficiency and minimize environmental impact.

Table of Comparison

| Aspect | Batch Production | On-Demand Manufacturing |

|---|---|---|

| Production Volume | Large quantities per batch | Customized, small quantities |

| Lead Time | Longer due to batch setup | Shorter, starts after order received |

| Inventory | High inventory levels | Minimal inventory, just-in-time |

| Cost Efficiency | Lower cost per unit at scale | Higher cost per unit, reduced waste |

| Flexibility | Low, fixed designs per batch | High, customizable products |

| Risk | Overproduction and unsold stock | Demand-driven, lower risk of excess |

| Use Case | Standard apparel lines, seasonal items | Custom apparel, rapid trend response |

Understanding Batch Production in Apparel

Batch production in apparel involves manufacturing a set quantity of garments in one production run, optimizing cost-efficiency and inventory management. This method allows brands to maintain consistent quality control and reduce per-unit production costs by leveraging economies of scale. Apparel companies use batch production to meet predictable demand while balancing lead times and minimizing waste.

What Is On-Demand Manufacturing?

On-demand manufacturing in apparel involves producing garments only after a customer places an order, minimizing excess inventory and reducing waste. This approach leverages digital technologies and automated production lines to deliver customized clothing quickly and efficiently. Brands benefit from improved cash flow and sustainability by aligning production closely with actual consumer demand.

Key Differences Between Batch and On-Demand Production

Batch production in apparel involves creating a fixed quantity of garments before moving to the next stage, ensuring cost efficiency and consistency in large orders. On-demand manufacturing produces items only when an order is placed, reducing inventory risks and allowing for greater customization and rapid response to market trends. Key differences include production volume, lead time, inventory management, and flexibility, with batch favoring economies of scale and on-demand prioritizing agility and minimal waste.

Cost Implications for Apparel Brands

Batch production in apparel manufacturing often results in lower unit costs due to economies of scale, making it cost-effective for large volume orders. On-demand manufacturing reduces inventory expenses and minimizes markdowns by producing only what is sold, which can lead to higher per-unit costs but improved cash flow management. Apparel brands must weigh upfront investment and inventory risk against flexibility and responsiveness when choosing between batch production and on-demand manufacturing.

Impact on Inventory Management

Batch production in apparel leads to larger inventory volumes, increasing storage costs and risk of unsold stock, while on-demand manufacturing minimizes inventory by producing items only after customer orders. This shift toward on-demand manufacturing enhances inventory accuracy and reduces waste, optimizing working capital and supply chain responsiveness. Apparel companies leveraging on-demand models can achieve leaner inventory management, aligning production closely with market demand and reducing markdowns.

Speed to Market: Batch vs On-Demand

Batch production in apparel offers faster initial turnaround by producing large quantities at once, reducing setup time per unit and enabling quicker fulfillment for planned collections. On-demand manufacturing accelerates speed to market for trending or customized items by eliminating inventory delays, allowing brands to respond rapidly to real-time consumer demands. Brands balancing speed with flexibility often integrate both methods to optimize delivery timelines and minimize overproduction risks.

Customization and Personalization Opportunities

Batch production in apparel manufacturing enables limited customization through predefined design variations, making it cost-effective for moderate personalization. On-demand manufacturing offers superior customization and personalization opportunities by producing garments individually based on specific customer preferences, reducing inventory waste. Brands leveraging on-demand methods can rapidly respond to trends and customer demands, enhancing consumer satisfaction with unique, tailored apparel.

Sustainability Considerations in Manufacturing Methods

Batch production in apparel manufacturing often results in excess inventory and higher waste due to overproduction, whereas on-demand manufacturing minimizes material waste by producing items only when ordered. On-demand methods reduce energy consumption and carbon footprint by cutting down storage needs and unsold stock disposal. Sustainability gains from on-demand manufacturing align with circular economy principles by promoting resource efficiency and reducing landfill contributions.

Scalability and Flexibility for Fashion Brands

Batch production offers scalability by enabling fashion brands to produce large quantities of apparel cost-effectively, capitalizing on economies of scale. On-demand manufacturing enhances flexibility, allowing brands to swiftly respond to market trends and customize products without excessive inventory risks. Combining both methods can optimize production efficiency while aligning with dynamic consumer demands.

Choosing the Right Production Model for Your Apparel Line

Batch production offers cost efficiency and consistent quality for established apparel lines with predictable demand, leveraging economies of scale to minimize per-unit costs. On-demand manufacturing reduces inventory risk and allows for rapid response to market trends, ideal for startups or brands emphasizing customization and sustainability. Selecting the right model depends on factors such as volume forecasts, cash flow, lead times, and the degree of product variation in your apparel collection.

Batch production vs On-demand manufacturing Infographic

productdif.com

productdif.com