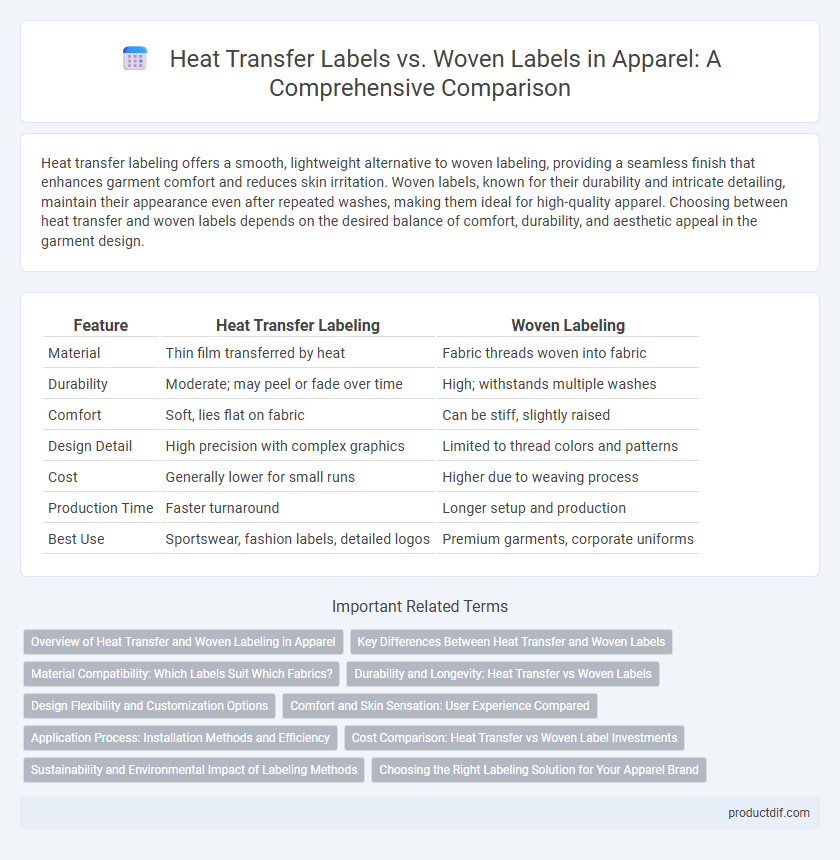

Heat transfer labeling offers a smooth, lightweight alternative to woven labeling, providing a seamless finish that enhances garment comfort and reduces skin irritation. Woven labels, known for their durability and intricate detailing, maintain their appearance even after repeated washes, making them ideal for high-quality apparel. Choosing between heat transfer and woven labels depends on the desired balance of comfort, durability, and aesthetic appeal in the garment design.

Table of Comparison

| Feature | Heat Transfer Labeling | Woven Labeling |

|---|---|---|

| Material | Thin film transferred by heat | Fabric threads woven into fabric |

| Durability | Moderate; may peel or fade over time | High; withstands multiple washes |

| Comfort | Soft, lies flat on fabric | Can be stiff, slightly raised |

| Design Detail | High precision with complex graphics | Limited to thread colors and patterns |

| Cost | Generally lower for small runs | Higher due to weaving process |

| Production Time | Faster turnaround | Longer setup and production |

| Best Use | Sportswear, fashion labels, detailed logos | Premium garments, corporate uniforms |

Overview of Heat Transfer and Woven Labeling in Apparel

Heat transfer labeling in apparel involves applying a printed design directly onto fabric using heat and pressure, resulting in smooth, flexible labels that do not irritate the skin. Woven labeling consists of interlacing threads to create durable, high-quality fabric labels often sewn into garments for long-lasting identification and branding. Both methods offer distinct advantages: heat transfer labels provide a seamless finish ideal for performance wear, while woven labels emphasize durability and premium craftsmanship.

Key Differences Between Heat Transfer and Woven Labels

Heat transfer labels offer a smooth, seamless application directly onto fabric, making them ideal for activewear and garments requiring minimal irritation, while woven labels provide a textured, durable option that conveys premium quality and longevity. Heat transfer labels use a heat-activated adhesive, enabling intricate designs with vibrant colors and fine details, whereas woven labels are created from interlaced threads, offering strength and resistance to wear and tear. The choice between heat transfer and woven labels depends on garment type, desired aesthetic, and durability requirements.

Material Compatibility: Which Labels Suit Which Fabrics?

Heat transfer labels excel on synthetic fabrics like polyester and nylon due to their thin, flexible design that adheres seamlessly without altering fabric texture. Woven labels are ideal for natural fibers such as cotton and linen, providing durability and a textured, high-quality finish that withstands repeated washing. Choosing the right label depends on fabric type: heat transfer labels suit smooth, stretchy materials, while woven labels complement thicker, woven textiles.

Durability and Longevity: Heat Transfer vs Woven Labels

Woven labels offer superior durability and longevity due to their tightly woven fibers that resist fraying and withstand multiple washes, making them ideal for long-lasting apparel branding. Heat transfer labels, while smooth and comfortable against the skin, tend to degrade faster with repeated exposure to heat and washing, often peeling or fading over time. Choosing woven labels ensures consistent appearance and durability in high-wear garments, whereas heat transfer labels suit short-term or delicate-use applications.

Design Flexibility and Customization Options

Heat transfer labeling offers superior design flexibility with the ability to reproduce intricate graphics, gradients, and multiple colors without adding bulk to the garment. Woven labeling excels in durability and texture but is limited in color complexity and fine detail customization. Apparel manufacturers often choose heat transfer labels for vibrant, highly customizable designs, while woven labels suit classic, textured brand identification.

Comfort and Skin Sensation: User Experience Compared

Heat transfer labeling offers a smooth, lightweight feel that enhances wearer comfort by eliminating the irritation commonly caused by woven labels with raised edges or seams. Woven labels, while durable, often create pressure points or chafing against sensitive skin, reducing overall comfort during extended wear. The soft, flexible nature of heat transfer labels makes them ideal for activewear and children's clothing, where comfort and skin sensation are critical to user experience.

Application Process: Installation Methods and Efficiency

Heat transfer labeling involves applying a printed design onto fabric using heat and pressure, resulting in a smooth, flexible finish ideal for intricate patterns and fast production times. Woven labeling requires weaving threads into a fabric strip before sewing it onto garments, offering durability and a premium look but involving longer installation processes and potential sewing time. Heat transfer labels excel in efficiency for bulk applications with minimal added labor, while woven labels are preferred for high-end apparel demanding robust, long-lasting identity tags.

Cost Comparison: Heat Transfer vs Woven Label Investments

Heat transfer labeling offers a lower initial investment compared to woven labels, as it eliminates the need for expensive weaving machinery and skilled labor. Woven labels require higher upfront costs due to complex production processes involving looms and thread materials, but they provide greater durability and premium texture. For large-scale apparel production, heat transfer labels reduce per-unit costs, while woven labels justify the investment through enhanced brand perception and longevity.

Sustainability and Environmental Impact of Labeling Methods

Heat transfer labeling reduces material waste and energy consumption compared to woven labeling, which requires additional fabric and chemicals for weaving and dyeing processes. The absence of sewing in heat transfer labels minimizes water use and pollution from thread production and treatment. Woven labels, while durable, often involve resource-intensive manufacturing, making heat transfer labels a more sustainable option for eco-conscious apparel brands.

Choosing the Right Labeling Solution for Your Apparel Brand

Heat transfer labeling offers a seamless, lightweight option ideal for activewear and garments requiring flexibility, while woven labeling provides durability and a premium feel suited for high-end apparel. Evaluating fabric type, brand aesthetics, and care instructions helps determine the optimal labeling method. Prioritizing comfort and brand visibility ensures the chosen solution enhances both wearer experience and brand recognition.

Heat Transfer Labeling vs Woven Labeling Infographic

productdif.com

productdif.com