Push-fit fittings offer a quick and tool-free installation for plumbing fixtures, making them ideal for DIY pet owners seeking convenience and reliability. Compression fittings provide a robust, leak-resistant connection, preferred for applications requiring high durability and pressure tolerance in pet plumbing systems. Choosing between the two depends on the balance between ease of use and long-term performance in maintaining safe water flow for pets.

Table of Comparison

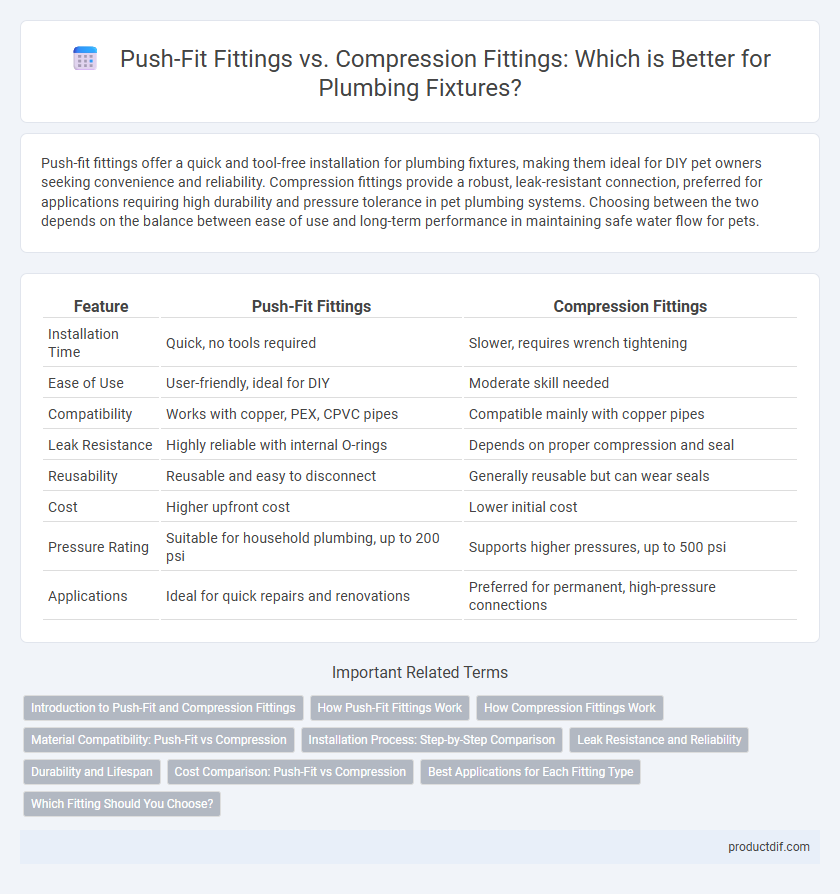

| Feature | Push-Fit Fittings | Compression Fittings |

|---|---|---|

| Installation Time | Quick, no tools required | Slower, requires wrench tightening |

| Ease of Use | User-friendly, ideal for DIY | Moderate skill needed |

| Compatibility | Works with copper, PEX, CPVC pipes | Compatible mainly with copper pipes |

| Leak Resistance | Highly reliable with internal O-rings | Depends on proper compression and seal |

| Reusability | Reusable and easy to disconnect | Generally reusable but can wear seals |

| Cost | Higher upfront cost | Lower initial cost |

| Pressure Rating | Suitable for household plumbing, up to 200 psi | Supports higher pressures, up to 500 psi |

| Applications | Ideal for quick repairs and renovations | Preferred for permanent, high-pressure connections |

Introduction to Push-Fit and Compression Fittings

Push-fit fittings offer a tool-free connection, enabling quick and secure attachment by simply pushing the pipe into the fitting, ideal for both copper and plastic pipes. Compression fittings utilize a threaded nut and ring compression mechanism to create a watertight seal, commonly used in residential plumbing applications for metal or plastic tubing. Both fitting types provide reliable joints, but push-fit fittings excel in ease of installation while compression fittings are valued for their durable, mechanical seal.

How Push-Fit Fittings Work

Push-fit fittings use an internal O-ring and metal teeth to create a watertight seal by simply pushing the pipe into the fitting without the need for soldering or special tools. The O-ring compresses against the pipe to prevent leaks, while the metal teeth grip the pipe securely to maintain connection under pressure. This quick and reliable connection method makes push-fit fittings ideal for both professional plumbers and DIY projects in residential and commercial plumbing systems.

How Compression Fittings Work

Compression fittings create a watertight seal by using a compression ring, or ferrule, which is compressed onto the pipe as the fitting's nut is tightened. This compression deforms the ferrule, gripping the pipe securely and preventing leaks under pressure. Commonly made of brass or copper, compression fittings are ideal for joining pipes in plumbing systems where soldering or welding is impractical.

Material Compatibility: Push-Fit vs Compression

Push-fit fittings excel in material compatibility by effortlessly connecting to various pipe types, including copper, PEX, and CPVC, without requiring additional tools or sealants. Compression fittings, on the other hand, rely on a compression ring and nut to create a seal, which can limit their effectiveness with softer materials like PEX and require precise installation to avoid leaks. Pipe system designers often prefer push-fit fittings for diverse plumbing materials due to their ease of use and reliable seals across different pipe compositions.

Installation Process: Step-by-Step Comparison

Push-fit fittings require simply cutting the pipe squarely, inserting it straight into the fitting, and securing it with an internal O-ring and grip ring for a watertight seal. Compression fittings involve sliding a compression nut and ring onto the pipe, inserting the pipe into the fixture, and tightening the nut onto the fitting body to compress the ring and create a seal. Push-fit installations typically save time due to fewer tools and steps, whereas compression fittings demand careful tightening to avoid leaks but provide strong, reliable joints.

Leak Resistance and Reliability

Push-fit fittings provide excellent leak resistance due to their built-in O-ring seals that create a secure, watertight connection without the need for additional tools or sealants. Compression fittings rely on a tightly compressed ferrule to prevent leaks but require precise installation to maintain reliability over time. Overall, push-fit fittings offer greater consistency in preventing leaks, especially in situations prone to vibration or thermal expansion.

Durability and Lifespan

Push-fit fittings offer ease of installation but tend to have a shorter lifespan due to potential wear on O-rings and seals, making them less durable in high-pressure or long-term applications. Compression fittings provide superior durability by creating a tighter seal through metal compression, resulting in a longer service life suitable for both residential and commercial plumbing systems. Choosing the right fitting depends on the plumbing environment, with compression fittings preferred for durability and longevity.

Cost Comparison: Push-Fit vs Compression

Push-fit fittings generally incur higher upfront costs than compression fittings due to their advanced design and ease of installation, which reduces labor expenses over time. Compression fittings are more affordable initially but may require more maintenance and skilled labor, potentially increasing overall project costs. Evaluating total expenses, including material prices and installation time, is essential for accurate cost comparison in plumbing projects.

Best Applications for Each Fitting Type

Push-fit fittings excel in DIY plumbing projects and emergency repairs due to their tool-free installation and reliable watertight seal, making them ideal for copper, CPVC, and PEX pipes in residential water supply lines. Compression fittings are best suited for high-pressure applications and metal piping systems, such as brass or copper tubing in heating and gas lines, where a strong, mechanical seal withstands temperature and pressure fluctuations. Selecting the appropriate fitting depends on pipe material compatibility, installation speed, and the specific pressure requirements of the plumbing system.

Which Fitting Should You Choose?

Push-fit fittings offer quick, tool-free installation, making them ideal for DIY projects and emergency repairs, while compression fittings provide a more secure, leak-resistant connection suitable for high-pressure systems and long-term durability. Choosing between the two depends on the specific plumbing application, pipe material, and installation skill level. For ease and speed, push-fit fittings are preferred; for reliability and longevity, compression fittings are the better option.

Push-Fit Fittings vs Compression Fittings Infographic

productdif.com

productdif.com