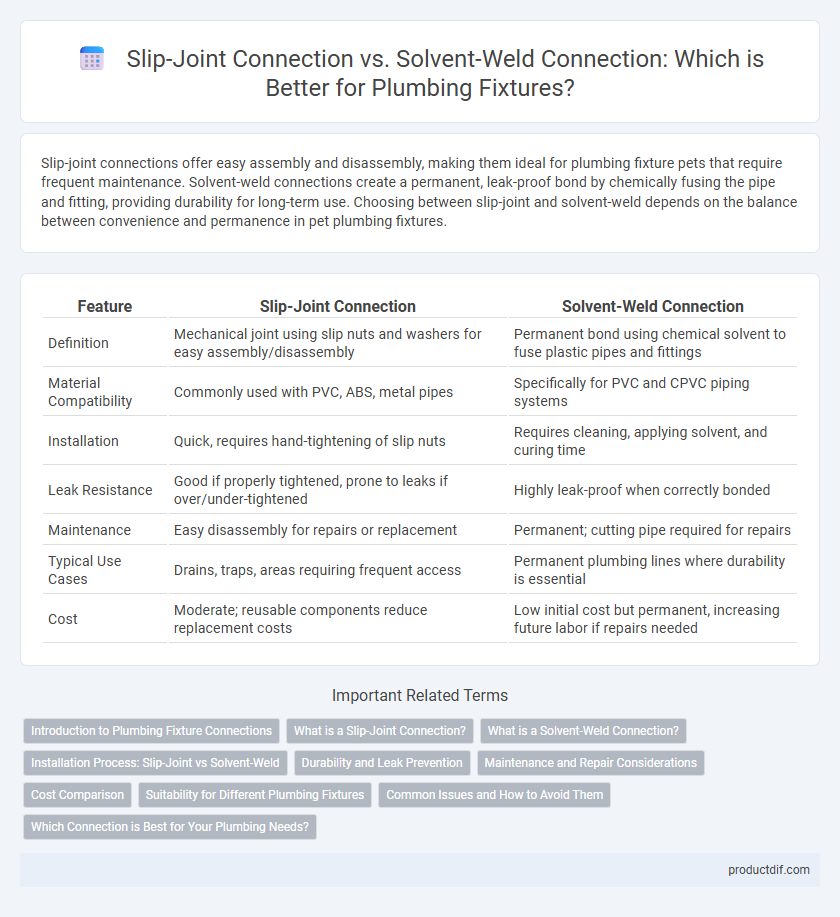

Slip-joint connections offer easy assembly and disassembly, making them ideal for plumbing fixture pets that require frequent maintenance. Solvent-weld connections create a permanent, leak-proof bond by chemically fusing the pipe and fitting, providing durability for long-term use. Choosing between slip-joint and solvent-weld depends on the balance between convenience and permanence in pet plumbing fixtures.

Table of Comparison

| Feature | Slip-Joint Connection | Solvent-Weld Connection |

|---|---|---|

| Definition | Mechanical joint using slip nuts and washers for easy assembly/disassembly | Permanent bond using chemical solvent to fuse plastic pipes and fittings |

| Material Compatibility | Commonly used with PVC, ABS, metal pipes | Specifically for PVC and CPVC piping systems |

| Installation | Quick, requires hand-tightening of slip nuts | Requires cleaning, applying solvent, and curing time |

| Leak Resistance | Good if properly tightened, prone to leaks if over/under-tightened | Highly leak-proof when correctly bonded |

| Maintenance | Easy disassembly for repairs or replacement | Permanent; cutting pipe required for repairs |

| Typical Use Cases | Drains, traps, areas requiring frequent access | Permanent plumbing lines where durability is essential |

| Cost | Moderate; reusable components reduce replacement costs | Low initial cost but permanent, increasing future labor if repairs needed |

Introduction to Plumbing Fixture Connections

Slip-joint connections in plumbing fixtures provide easy disassembly and maintenance by using a washer and nut to secure pipes without permanent bonding. Solvent-weld connections create a durable, leak-proof seal by chemically fusing PVC or CPVC pipes and fittings, making them ideal for permanent, underground, or hard-to-access installations. Choosing between slip-joint and solvent-weld connections depends on the need for flexibility in repairs versus long-term reliability in plumbing systems.

What is a Slip-Joint Connection?

A slip-joint connection in plumbing is a type of mechanical joint that allows pipes to be connected and disassembled easily without permanent bonding. It typically uses a compression nut and a slip nut to create a watertight seal around the pipe, making it ideal for connecting sinks, drains, and trap assemblies. Slip-joint connections offer flexibility and ease of maintenance compared to solvent-weld connections, which require chemical adhesives to bond pipes permanently.

What is a Solvent-Weld Connection?

A solvent-weld connection is a type of plumbing joint where a solvent cement chemically fuses PVC or CPVC pipes and fittings, creating a permanent, watertight seal. This method involves applying a solvent that softens the surfaces of the materials before joining them, resulting in a strong, leak-proof bond ideal for drain, waste, and vent systems. Unlike slip-joint connections, solvent-weld joints cannot be disassembled, providing enhanced durability and resistance to leaks in plumbing fixtures.

Installation Process: Slip-Joint vs Solvent-Weld

Slip-joint connections allow easy installation by hand-tightening a nut over a compression washer, requiring no special tools or adhesives, making them ideal for accessible plumbing fixtures and repairs. Solvent-weld connections involve applying a chemical solvent to both pipe and fitting surfaces before joining, creating a strong, permanent bond that demands curing time and precise cleaning during installation. Choosing between slip-joint and solvent-weld connections affects installation speed, durability, and the necessity for future disassembly in plumbing systems.

Durability and Leak Prevention

Slip-joint connections offer moderate durability and ease of installation but may be prone to leaks over time due to gasket wear or loosening. Solvent-weld connections create a strong, permanent bond between pipes, significantly enhancing durability and eliminating leaks by fusing the plastic surfaces together. For long-term leak prevention and robust durability, solvent-weld connections are preferred in plumbing fixture applications.

Maintenance and Repair Considerations

Slip-joint connections offer easier maintenance and repair due to their detachable design, allowing quick disassembly without specialized tools. Solvent-weld connections provide a more permanent seal but require cutting and re-gluing pipes for repairs, increasing labor and time involved. Choosing slip-joint fittings can reduce downtime and simplify troubleshooting in plumbing systems where frequent access is anticipated.

Cost Comparison

Slip-joint connections typically cost less upfront due to their reusable design and simpler installation process compared to solvent-weld connections, which require specific adhesives and curing time. While solvent-weld connections offer a more permanent and leak-resistant seal, the additional cost of solvent cement and potential need for professional installation can increase overall expenses. For budget-conscious plumbing projects, slip-joint fittings provide cost-effective flexibility without sacrificing basic functionality.

Suitability for Different Plumbing Fixtures

Slip-joint connections are highly suitable for sinks, lavatories, and traps where frequent disassembly for maintenance or cleaning is required due to their ease of installation and reuse. Solvent-weld connections provide a more permanent, leak-proof seal ideal for drain-waste-vent (DWV) piping and fixtures where long-term, durable joints are necessary. Selecting between slip-joint and solvent-weld connections depends on fixture accessibility, maintenance needs, and the requirement for a watertight, long-lasting connection.

Common Issues and How to Avoid Them

Slip-joint connections often face leaks due to improper alignment or worn-out washers, while solvent-weld connections can suffer from weak joints if the pipe and fitting surfaces are not thoroughly cleaned before application. To avoid these issues, ensure slip-joint nuts are tightened securely without overtightening and replace washers periodically, whereas solvent-weld joints require proper surface preparation and adequate curing time for the solvent cement. Regular inspection and maintenance are essential for both connection types to prevent plumbing failures and water damage.

Which Connection is Best for Your Plumbing Needs?

Slip-joint connections provide easy disassembly and are ideal for traps and drainpipes where access is frequently needed, while solvent-weld connections create a permanent, leak-proof seal best suited for water supply lines and long-term durability. Selecting the right connection depends on your plumbing requirements: choose slip-joint for flexibility and maintenance, or solvent-weld for a secure, long-lasting bond. Understanding the application and maintenance needs ensures the most effective and reliable plumbing system.

Slip-joint connection vs Solvent-weld connection Infographic

productdif.com

productdif.com