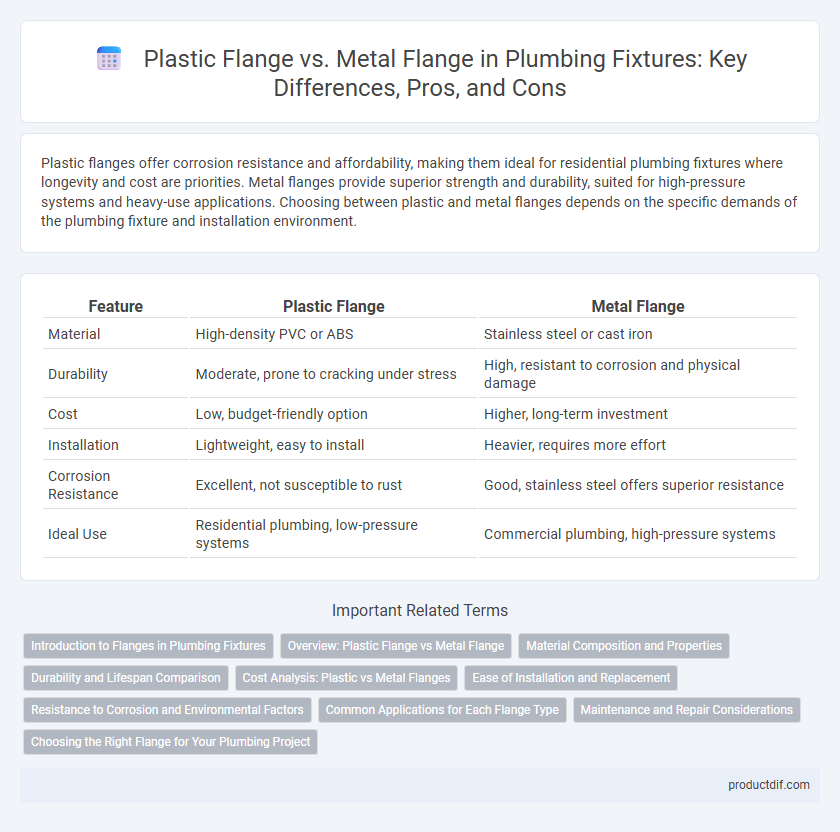

Plastic flanges offer corrosion resistance and affordability, making them ideal for residential plumbing fixtures where longevity and cost are priorities. Metal flanges provide superior strength and durability, suited for high-pressure systems and heavy-use applications. Choosing between plastic and metal flanges depends on the specific demands of the plumbing fixture and installation environment.

Table of Comparison

| Feature | Plastic Flange | Metal Flange |

|---|---|---|

| Material | High-density PVC or ABS | Stainless steel or cast iron |

| Durability | Moderate, prone to cracking under stress | High, resistant to corrosion and physical damage |

| Cost | Low, budget-friendly option | Higher, long-term investment |

| Installation | Lightweight, easy to install | Heavier, requires more effort |

| Corrosion Resistance | Excellent, not susceptible to rust | Good, stainless steel offers superior resistance |

| Ideal Use | Residential plumbing, low-pressure systems | Commercial plumbing, high-pressure systems |

Introduction to Flanges in Plumbing Fixtures

Plastic flanges in plumbing fixtures offer corrosion resistance and ease of installation, making them suitable for residential water systems and drainage applications. Metal flanges, commonly made from cast iron or stainless steel, provide superior strength and durability, ideal for high-pressure or industrial plumbing setups. Selecting between plastic and metal flanges depends on factors such as pipe material compatibility, environmental conditions, and load requirements in the plumbing system.

Overview: Plastic Flange vs Metal Flange

Plastic flanges offer corrosion resistance, lightweight construction, and cost-effectiveness, making them ideal for residential plumbing systems and non-corrosive applications. Metal flanges, typically made from stainless steel or cast iron, provide superior durability, strength, and heat resistance, suited for industrial or high-pressure plumbing fixtures. Choosing between plastic and metal flanges depends on factors like environmental conditions, load requirements, and budget constraints.

Material Composition and Properties

Plastic flange is typically made from PVC or ABS, offering corrosion resistance, lightweight structure, and flexibility, making it ideal for residential plumbing applications. Metal flange, often composed of cast iron, stainless steel, or brass, provides superior strength, durability, and high-temperature resistance, suitable for heavy-duty or industrial plumbing systems. The choice between plastic and metal flanges depends on factors like mechanical stress, environmental exposure, and compatibility with existing piping materials.

Durability and Lifespan Comparison

Metal flanges exhibit superior durability and a longer lifespan compared to plastic flanges due to their resistance to cracking, corrosion, and higher pressure tolerance. Plastic flanges, while more cost-effective and resistant to certain chemicals, generally degrade faster under UV exposure and mechanical stress. Choosing metal flanges ensures a more reliable and long-term plumbing fixture, especially in demanding environments.

Cost Analysis: Plastic vs Metal Flanges

Plastic flanges typically offer a lower initial cost compared to metal flanges, making them a budget-friendly option for plumbing installations. While metal flanges are more expensive upfront, they provide greater durability and resistance to high temperatures and corrosion, potentially reducing long-term maintenance expenses. Evaluating the total cost of ownership, including installation, lifespan, and repair frequency, is crucial when choosing between plastic and metal plumbing flanges.

Ease of Installation and Replacement

Plastic flanges offer lightweight construction and flexibility, making them easier to install in tight spaces and reducing the need for specialized tools compared to metal flanges. Metal flanges provide durability and resistance to corrosion but often require precise alignment and heavier tools for installation and replacement, which can extend labor time. Choosing plastic flanges can streamline plumbing fixture projects by minimizing installation complexity and expediting future replacement tasks.

Resistance to Corrosion and Environmental Factors

Plastic flanges offer superior resistance to corrosion and environmental factors compared to metal flanges, as they do not rust or degrade when exposed to moisture and chemicals. Metal flanges, typically made from stainless steel or cast iron, require protective coatings to prevent corrosion but may still be vulnerable in harsh or acidic environments. The corrosion resistance of plastic flanges makes them ideal for plumbing systems in environments prone to high humidity, chemical exposure, or saltwater conditions.

Common Applications for Each Flange Type

Plastic flanges are commonly used in residential plumbing systems, drainage, and irrigation setups due to their corrosion resistance and lightweight properties. Metal flanges are preferred in industrial applications, high-pressure water systems, and HVAC duct connections for their durability and strength under extreme conditions. Each type supports specific plumbing fixtures based on environmental demands and performance requirements.

Maintenance and Repair Considerations

Plastic flanges offer corrosion resistance and easier installation, reducing long-term maintenance needs but may be prone to cracking under high stress or temperature fluctuations. Metal flanges, typically made from steel or brass, provide superior durability and impact resistance, making them preferable for heavy-duty plumbing systems but require regular inspection to prevent rust and corrosion. Repairing plastic flanges often involves simple replacement due to material brittleness, while metal flange repairs may require welding or sealing to maintain system integrity.

Choosing the Right Flange for Your Plumbing Project

Plastic flanges offer lightweight construction and corrosion resistance, making them ideal for residential plumbing systems and non-corrosive environments. Metal flanges provide superior strength and durability, suitable for high-pressure applications and commercial plumbing projects requiring long-lasting performance. Selecting the right flange depends on factors like water pressure, environmental exposure, and budget constraints to ensure optimal functionality and longevity.

Plastic flange vs Metal flange Infographic

productdif.com

productdif.com