Slip joint and threaded joint are two common plumbing fixture connections, each offering distinct advantages. Slip joints provide quick and easy assembly with a compression nut and washer, ideal for temporary setups and repairs, while threaded joints ensure a stronger, more permanent seal by screwing directly into the fixture or pipe, reducing the risk of leaks. Choosing between slip joint and threaded joint depends on the specific plumbing application, required durability, and ease of maintenance.

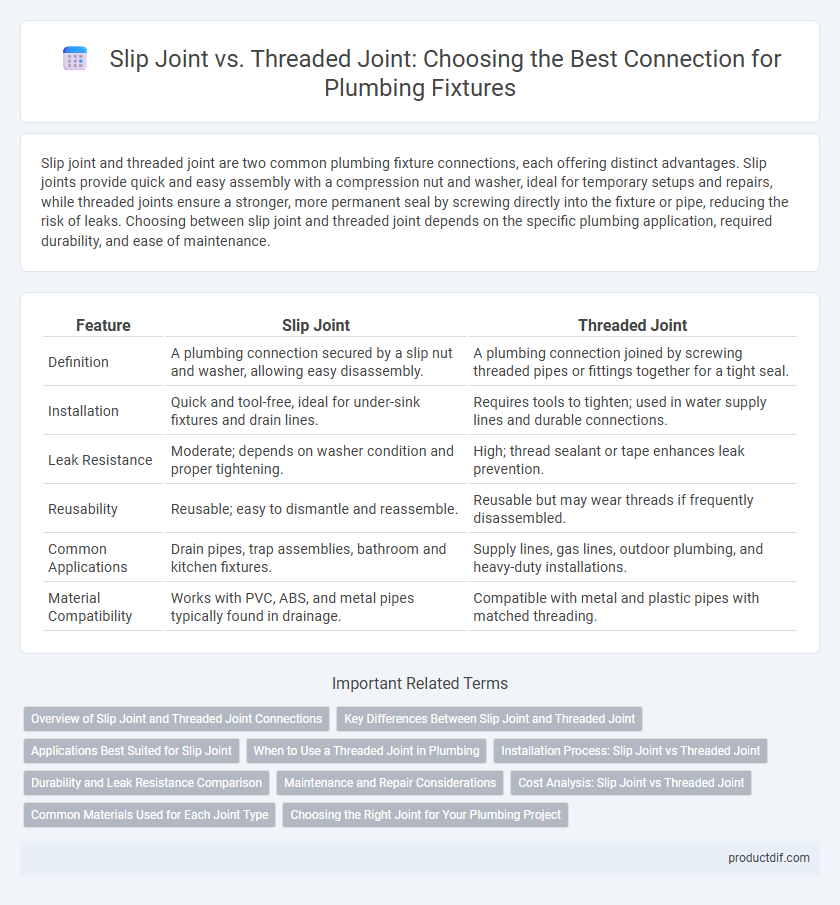

Table of Comparison

| Feature | Slip Joint | Threaded Joint |

|---|---|---|

| Definition | A plumbing connection secured by a slip nut and washer, allowing easy disassembly. | A plumbing connection joined by screwing threaded pipes or fittings together for a tight seal. |

| Installation | Quick and tool-free, ideal for under-sink fixtures and drain lines. | Requires tools to tighten; used in water supply lines and durable connections. |

| Leak Resistance | Moderate; depends on washer condition and proper tightening. | High; thread sealant or tape enhances leak prevention. |

| Reusability | Reusable; easy to dismantle and reassemble. | Reusable but may wear threads if frequently disassembled. |

| Common Applications | Drain pipes, trap assemblies, bathroom and kitchen fixtures. | Supply lines, gas lines, outdoor plumbing, and heavy-duty installations. |

| Material Compatibility | Works with PVC, ABS, and metal pipes typically found in drainage. | Compatible with metal and plastic pipes with matched threading. |

Overview of Slip Joint and Threaded Joint Connections

Slip joint connections in plumbing fixtures use a compression mechanism allowing easy assembly and disassembly without special tools, making them ideal for drain pipes and traps. Threaded joints create a tight, leak-proof seal by screwing male and female threaded components together, commonly used for water supply lines and pipe fittings. Both connections serve essential roles in plumbing systems, with slip joints offering flexibility and threaded joints providing durable, high-pressure resistance.

Key Differences Between Slip Joint and Threaded Joint

Slip joints use a compression fitting mechanism with a slip nut and washer to create a watertight seal, allowing easy disassembly and adjustment, making them ideal for drain connections. Threaded joints rely on screw threads to join pipes or fixtures tightly together, providing a more permanent and secure connection suitable for water supply lines. Slip joints offer flexibility and quick installation, whereas threaded joints provide greater durability and resistance to leaks under pressure.

Applications Best Suited for Slip Joint

Slip joints are ideal for applications requiring easy disassembly and adjustments, commonly used in sink drains and traps where frequent maintenance or replacement may be needed. They provide a flexible, watertight seal without the need for specialized tools, making them perfect for residential plumbing fixtures and DIY repairs. Slip joints excel in situations that demand quick installation or removal, especially in tight spaces with limited access.

When to Use a Threaded Joint in Plumbing

Threaded joints are ideal in plumbing systems requiring a secure, leak-resistant connection that can withstand higher pressure and temperature variations, such as in gas lines or water supply pipes. They offer durability and ease of disassembly for maintenance or repairs, making them suitable for exposed areas where frequent access is needed. When corrosion resistance and long-term reliability are priorities, using materials like brass or stainless steel threaded joints ensures optimal performance.

Installation Process: Slip Joint vs Threaded Joint

Slip joint installation involves aligning the pipe sections and securing them with a compression nut and slip washer, allowing for quick adjustments and easy disassembly. Threaded joint installation requires carefully threading the pipe ends and applying pipe joint compound or Teflon tape to ensure a watertight seal, often demanding precise torque to avoid leaks. Slip joints offer faster, tool-free installation, while threaded joints provide a more secure, permanent connection but with increased installation complexity.

Durability and Leak Resistance Comparison

Slip joints provide moderate durability but are more prone to leaks due to their reliance on compression washers, which can degrade over time. Threaded joints offer superior leak resistance and long-term durability by forming a tight, mechanical seal that withstands higher pressure and temperature variations. Proper installation and quality materials enhance the effectiveness of both joint types in plumbing fixtures.

Maintenance and Repair Considerations

Slip joints offer easier maintenance and repair due to their simple hand-tightened design, allowing quick disassembly without special tools. Threaded joints require careful alignment and use of sealing tape or compound to prevent leaks, making repairs more time-consuming and needing appropriate tools. Slip joints are ideal for frequent access, while threaded joints provide a more permanent, secure connection but demand skilled handling during maintenance.

Cost Analysis: Slip Joint vs Threaded Joint

Slip joints typically offer lower installation costs due to their simple design and ease of assembly, reducing labor time and the need for specialized tools. Threaded joints incur higher initial expenses because of the precision manufacturing required and the increased labor for careful alignment and threading. Over time, slip joints may demand more maintenance and replacement, potentially increasing overall costs compared to the more durable and leak-resistant threaded joints.

Common Materials Used for Each Joint Type

Slip joints commonly use materials such as PVC, ABS plastic, and brass, chosen for their flexibility and ease of assembly, especially in residential drainage systems. Threaded joints frequently employ metals like galvanized steel, brass, and copper due to their strength and durability in high-pressure water supply lines. The selection of materials directly impacts the joint's resistance to corrosion, leak potential, and suitability for hot or cold water applications.

Choosing the Right Joint for Your Plumbing Project

Slip joints offer easy installation and adjustment, ideal for connecting sink drains and traps with limited space, while threaded joints provide a more secure and durable seal suitable for high-pressure applications and permanent connections. Choosing the right joint depends on the project requirements, such as accessibility, pressure conditions, and the need for future maintenance. For residential plumbing, slip joints facilitate quick repairs, whereas threaded joints are preferred in systems requiring leak-resistant and long-lasting connections.

Slip Joint vs Threaded Joint Infographic

productdif.com

productdif.com