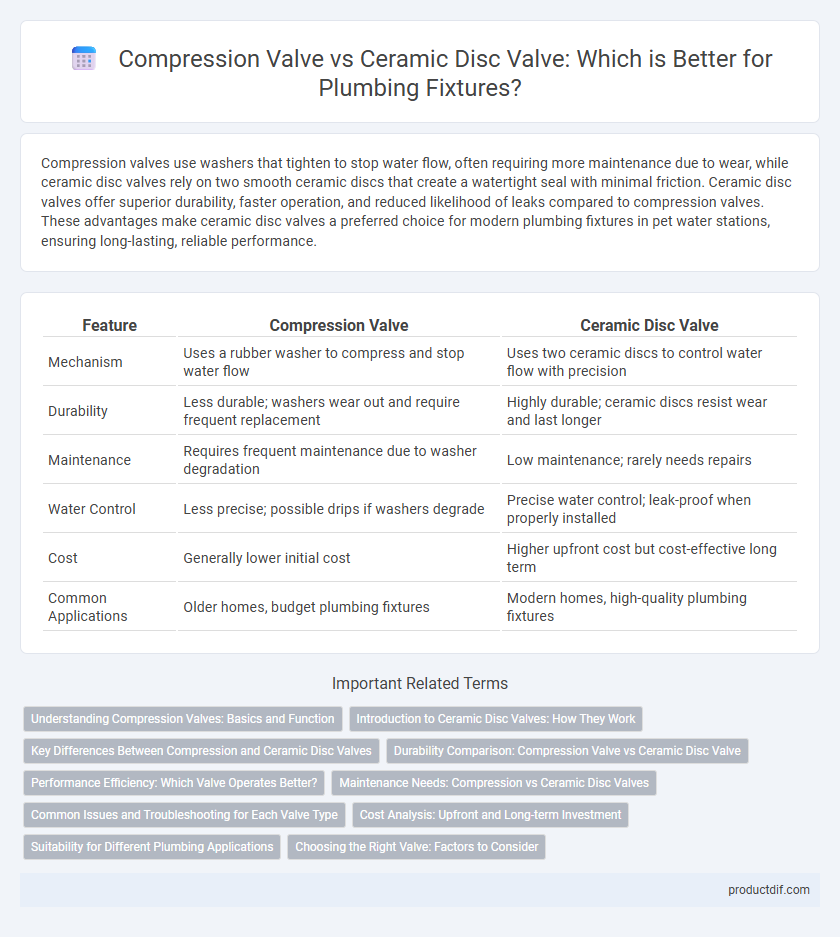

Compression valves use washers that tighten to stop water flow, often requiring more maintenance due to wear, while ceramic disc valves rely on two smooth ceramic discs that create a watertight seal with minimal friction. Ceramic disc valves offer superior durability, faster operation, and reduced likelihood of leaks compared to compression valves. These advantages make ceramic disc valves a preferred choice for modern plumbing fixtures in pet water stations, ensuring long-lasting, reliable performance.

Table of Comparison

| Feature | Compression Valve | Ceramic Disc Valve |

|---|---|---|

| Mechanism | Uses a rubber washer to compress and stop water flow | Uses two ceramic discs to control water flow with precision |

| Durability | Less durable; washers wear out and require frequent replacement | Highly durable; ceramic discs resist wear and last longer |

| Maintenance | Requires frequent maintenance due to washer degradation | Low maintenance; rarely needs repairs |

| Water Control | Less precise; possible drips if washers degrade | Precise water control; leak-proof when properly installed |

| Cost | Generally lower initial cost | Higher upfront cost but cost-effective long term |

| Common Applications | Older homes, budget plumbing fixtures | Modern homes, high-quality plumbing fixtures |

Understanding Compression Valves: Basics and Function

Compression valves control water flow by tightening or loosening a washer against a valve seat, effectively stopping or allowing water to pass. These valves rely on a simple mechanism where turning the handle compresses the washer, creating a seal to prevent leaks. Known for their straightforward design, compression valves are commonly used in traditional plumbing fixtures despite requiring occasional maintenance due to wear on washers.

Introduction to Ceramic Disc Valves: How They Work

Ceramic disc valves utilize two ceramic discs that slide over each other to control water flow, creating a near-frictionless seal that enhances durability and prevents leaks. Unlike compression valves, which rely on rubber washers that wear out over time, ceramic disc valves offer smoother operation and longer lifespan due to their hard, corrosion-resistant surfaces. This design significantly reduces maintenance needs and provides precise control over water temperature and pressure.

Key Differences Between Compression and Ceramic Disc Valves

Compression valves use rubber washers to control water flow by tightening and loosening, which can wear out over time, causing leaks. Ceramic disc valves feature two ceramic discs that slide over each other to regulate flow, offering greater durability and a longer lifespan compared to compression valves. The main differences include leak resistance, maintenance frequency, and smoothness of operation, with ceramic disc valves providing superior performance and reliability.

Durability Comparison: Compression Valve vs Ceramic Disc Valve

Ceramic disc valves offer superior durability compared to compression valves due to their robust, corrosion-resistant ceramic components that withstand wear and tear over time. Compression valves rely on rubber washers that degrade faster, leading to frequent leaks and maintenance. The longevity of ceramic disc valves reduces the need for repairs, making them a more reliable choice for plumbing fixtures.

Performance Efficiency: Which Valve Operates Better?

Ceramic disc valves provide superior performance efficiency compared to compression valves due to their durable, wear-resistant discs that offer smooth, drip-free operation and require less maintenance over time. Compression valves rely on rubber washers that wear out faster, leading to potential leaks and reduced efficiency as the valve ages. The advanced design of ceramic disc valves ensures more precise water control and longevity, making them the better choice for modern plumbing fixtures.

Maintenance Needs: Compression vs Ceramic Disc Valves

Compression valves require frequent maintenance due to the wear and tear of rubber washers that need regular replacement to prevent leaks. Ceramic disc valves offer superior durability with ceramic discs that resist wear and reduce the frequency of repairs and maintenance. Homeowners benefit from lower maintenance costs and longer service life when choosing ceramic disc valves over compression types.

Common Issues and Troubleshooting for Each Valve Type

Compression valves often face common issues such as worn washers causing leaks and difficulty in turning due to sediment buildup. Ceramic disc valves typically encounter problems like misalignment leading to slow leaks and debris accumulation affecting smooth operation. Troubleshooting compression valves involves replacing washers and cleaning valve seats, whereas ceramic disc valves require cleaning or replacing the ceramic discs to restore proper function.

Cost Analysis: Upfront and Long-term Investment

Compression valves typically have a lower upfront cost compared to ceramic disc valves, making them a budget-friendly option for basic plumbing fixtures. However, ceramic disc valves offer greater durability and require less maintenance, translating to lower long-term expenses and fewer replacement costs. When analyzing cost efficiency over time, ceramic disc valves provide a more economical investment despite their higher initial price.

Suitability for Different Plumbing Applications

Compression valves are suitable for low-pressure systems and traditional plumbing setups where precise flow control is less critical, making them ideal for residential bathrooms and older homes. Ceramic disc valves offer superior durability and smooth operation in high-pressure systems, commonly used in modern kitchens and commercial plumbing applications requiring frequent use and reliable leak prevention. Selecting the appropriate valve type depends on water pressure, usage frequency, and the specific plumbing system design requirements.

Choosing the Right Valve: Factors to Consider

Choosing the right valve for plumbing fixtures involves assessing durability, maintenance needs, and water efficiency. Compression valves offer simplicity and low cost but may require frequent adjustments due to washer wear, while ceramic disc valves provide long-lasting performance with smooth operation and minimal leaks. Consider water pressure compatibility, ease of repair, and lifespan to ensure optimal valve selection for your plumbing system.

compression valve vs ceramic disc valve Infographic

productdif.com

productdif.com