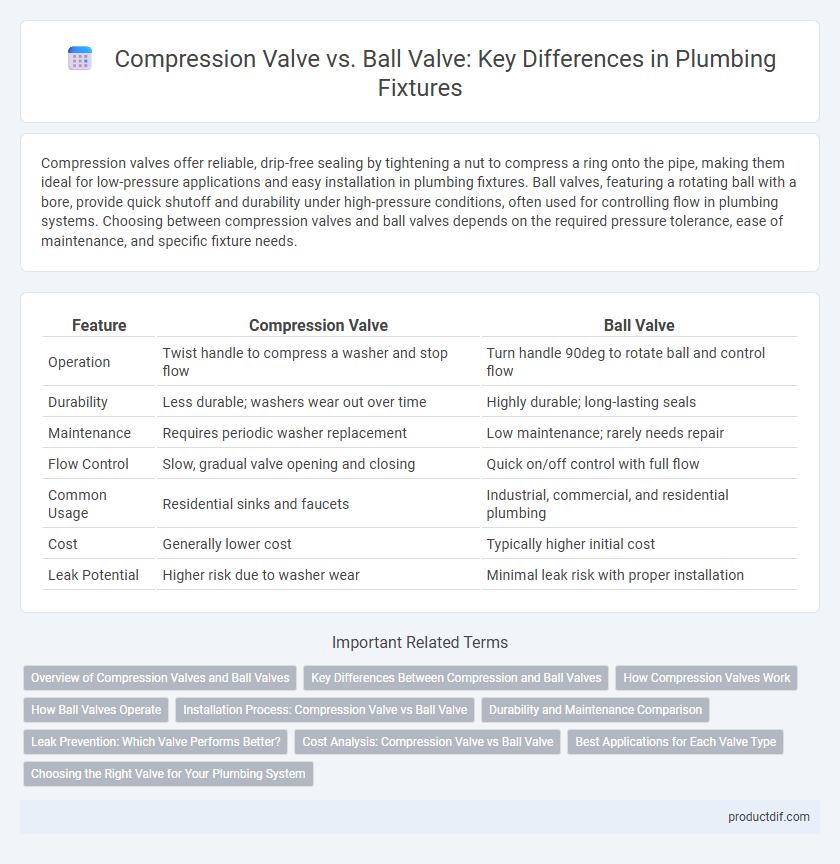

Compression valves offer reliable, drip-free sealing by tightening a nut to compress a ring onto the pipe, making them ideal for low-pressure applications and easy installation in plumbing fixtures. Ball valves, featuring a rotating ball with a bore, provide quick shutoff and durability under high-pressure conditions, often used for controlling flow in plumbing systems. Choosing between compression valves and ball valves depends on the required pressure tolerance, ease of maintenance, and specific fixture needs.

Table of Comparison

| Feature | Compression Valve | Ball Valve |

|---|---|---|

| Operation | Twist handle to compress a washer and stop flow | Turn handle 90deg to rotate ball and control flow |

| Durability | Less durable; washers wear out over time | Highly durable; long-lasting seals |

| Maintenance | Requires periodic washer replacement | Low maintenance; rarely needs repair |

| Flow Control | Slow, gradual valve opening and closing | Quick on/off control with full flow |

| Common Usage | Residential sinks and faucets | Industrial, commercial, and residential plumbing |

| Cost | Generally lower cost | Typically higher initial cost |

| Leak Potential | Higher risk due to washer wear | Minimal leak risk with proper installation |

Overview of Compression Valves and Ball Valves

Compression valves operate by compressing a rubber washer against a valve seat to stop water flow, making them ideal for low-pressure applications and offering straightforward repair. Ball valves use a rotating ball with a hole through the center to control flow, providing a durable, watertight seal suitable for high-pressure plumbing systems. Both valves serve distinct roles in plumbing fixtures, with compression valves favored for simplicity and ball valves valued for longevity and reliable shutoff.

Key Differences Between Compression and Ball Valves

Compression valves rely on a compressible ring to seal and control water flow, making them ideal for low-pressure applications and precise flow adjustments. Ball valves use a rotating ball with a hole to allow or block flow, providing a quick shut-off and high durability suitable for high-pressure plumbing systems. The key differences include operation mechanics, pressure tolerance, sealing effectiveness, and maintenance requirements.

How Compression Valves Work

Compression valves control water flow by tightening a metal ring, or compression ring, around a valve seat, creating a watertight seal. When the handle is turned, the valve stem compresses the ring, restricting or allowing water passage through the fixture. This mechanism is commonly used in plumbing fixtures for precise flow control and leak prevention in residential water supply lines.

How Ball Valves Operate

Ball valves operate using a spherical disc with a hole through the center that aligns with the flow when open, allowing water to pass freely. Turning the valve handle rotates the ball 90 degrees to either block or permit flow, ensuring a tight seal and easy operation. These valves provide reliable shutoff and minimal pressure drop compared to compression valves in plumbing fixtures.

Installation Process: Compression Valve vs Ball Valve

Compression valves require precise tightening of a compression nut onto a pipe to ensure a watertight seal, often demanding skilled manual adjustment during installation. Ball valves feature a straightforward installation process with threaded or soldered connections, allowing quicker setup and easier maintenance. Proper alignment and sealing are crucial for both valve types to prevent leaks and ensure long-lasting plumbing system performance.

Durability and Maintenance Comparison

Compression valves often require more frequent maintenance due to their washer-based mechanism, which can wear out and cause leaks over time. Ball valves, constructed with a solid brass or stainless steel ball, offer superior durability and require less maintenance because of their robust design and fewer moving parts. The extended lifespan and low upkeep make ball valves a preferred choice for long-term plumbing fixtures where reliability is critical.

Leak Prevention: Which Valve Performs Better?

Ball valves outperform compression valves in leak prevention due to their robust design, featuring a spherical disc that creates a tight seal when closed, minimizing water leakage. Compression valves rely on a compression nut and ferrule to seal, which can wear over time and increase the risk of leaks. For plumbing fixtures requiring reliable leak prevention, ball valves provide superior durability and long-term performance.

Cost Analysis: Compression Valve vs Ball Valve

Compression valves typically have a lower upfront cost compared to ball valves, making them a budget-friendly option for simple plumbing tasks. Ball valves, while more expensive initially, offer greater durability and longer service life, which can reduce replacement and maintenance expenses over time. Choosing between the two requires weighing the initial investment against potential long-term savings based on usage frequency and system demands.

Best Applications for Each Valve Type

Compression valves are best suited for low-pressure applications such as residential water supply lines and garden hoses due to their simple design and ease of repair. Ball valves excel in high-pressure and high-flow systems, providing reliable shutoff and durability for industrial plumbing, gas lines, and large-scale water distribution. Selecting the appropriate valve type depends on specific requirements like pressure tolerance, flow control precision, and maintenance frequency.

Choosing the Right Valve for Your Plumbing System

Choosing the right valve for your plumbing system depends on factors like pressure control and durability; compression valves offer tight sealing for low-pressure lines, while ball valves provide robust shutoff with a quick quarter-turn operation. Compression valves are ideal for residential fixtures requiring maintenance ease, whereas ball valves excel in high-pressure applications due to their long-lasting, corrosion-resistant design. Evaluating flow control needs and valve lifespan ensures optimal performance and leak prevention in plumbing installations.

Compression valve vs Ball valve Infographic

productdif.com

productdif.com