Threaded connections in plumbing fixtures offer the advantage of easy disassembly and reusability, making them ideal for maintenance and repairs. Soldered connections provide a permanent, leak-proof seal that ensures durability and reliability in high-pressure systems. Choosing between threaded and soldered connections depends on the application requirements, with threaded fittings preferred for flexibility and soldered joints favored for long-term stability.

Table of Comparison

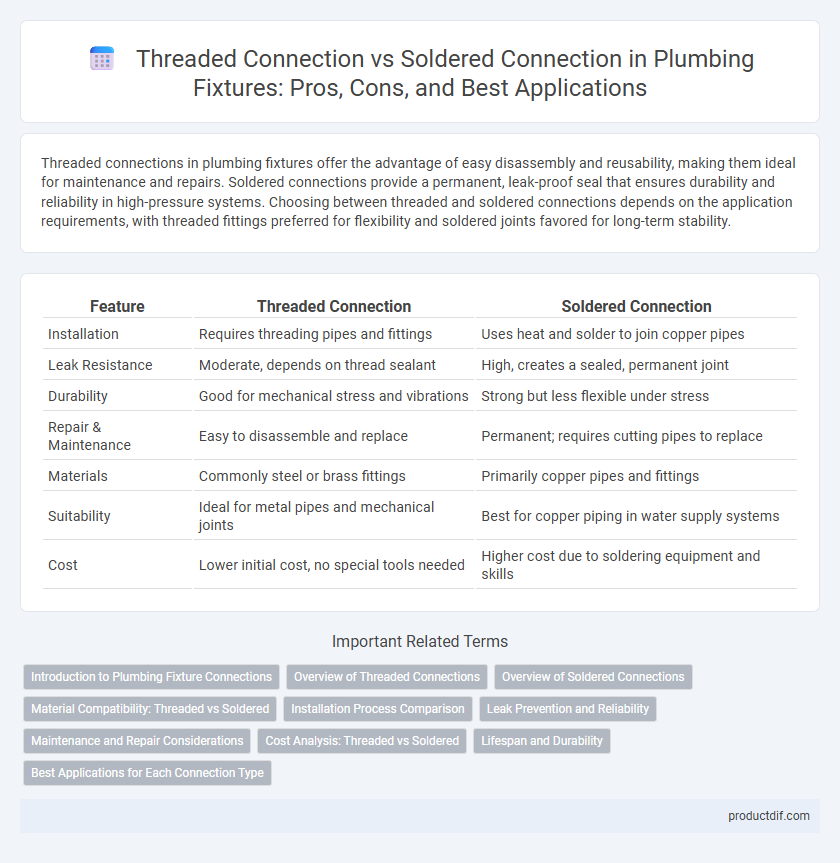

| Feature | Threaded Connection | Soldered Connection |

|---|---|---|

| Installation | Requires threading pipes and fittings | Uses heat and solder to join copper pipes |

| Leak Resistance | Moderate, depends on thread sealant | High, creates a sealed, permanent joint |

| Durability | Good for mechanical stress and vibrations | Strong but less flexible under stress |

| Repair & Maintenance | Easy to disassemble and replace | Permanent; requires cutting pipes to replace |

| Materials | Commonly steel or brass fittings | Primarily copper pipes and fittings |

| Suitability | Ideal for metal pipes and mechanical joints | Best for copper piping in water supply systems |

| Cost | Lower initial cost, no special tools needed | Higher cost due to soldering equipment and skills |

Introduction to Plumbing Fixture Connections

Threaded connections in plumbing fixtures use screw-like threads to join pipes, providing a strong mechanical seal commonly found in metal piping systems such as galvanized steel and brass. Soldered connections involve melting a filler metal to bond copper pipes and fittings, creating leak-proof joints ideal for water supply lines. Choosing between threaded and soldered connections depends on pipe material, application, and the need for ease of disassembly or permanent, durable sealing.

Overview of Threaded Connections

Threaded connections in plumbing fixtures involve joining pipes or fittings using helical grooves that create a tight seal when twisted together, offering easy disassembly and reusability. These connections are commonly made from materials such as brass, galvanized steel, or stainless steel, suited for high-pressure applications and systems requiring regular maintenance. Threaded fittings are ideal for water, gas, and compressed air pipelines, providing a strong mechanical bond without the need for heat or solder.

Overview of Soldered Connections

Soldered connections in plumbing fixtures involve joining pipes by melting a filler metal into the joint, creating a strong, leak-proof seal often used with copper pipes. This method ensures durability and resists corrosion, making it ideal for water supply lines and heating systems. Proper soldering requires clean pipe surfaces, appropriate flux application, and controlled heating for a secure and lasting bond.

Material Compatibility: Threaded vs Soldered

Threaded connections in plumbing fixtures are best suited for materials like galvanized steel and brass, offering a secure fit without the need for heat, making them ideal for dissimilar metal joints. Soldered connections require copper or copper-compatible alloys, ensuring a strong, leak-proof bond through melting solder around precisely cleaned and fitted joints. Choosing the right connection type depends on material compatibility to prevent corrosion and maintain system integrity over time.

Installation Process Comparison

Threaded connections in plumbing fixtures install by screwing pipes and fittings together, requiring precise threading and the use of sealing tape or compound to prevent leaks. Soldered connections involve heating the joint and applying solder to fuse copper pipes, demanding skilled technique and safety precautions during the installation process. Threaded connections offer easier disassembly and maintenance, while soldered joints provide a permanent, strong seal ideal for high-pressure applications.

Leak Prevention and Reliability

Threaded connections in plumbing fixtures provide a mechanical seal that offers ease of installation and disassembly but may be prone to leaks if not properly tightened or sealed with thread tape. Soldered connections create a permanent, watertight bond through the melting of solder metal, enhancing leak prevention and long-term reliability in copper piping systems. The choice between threaded and soldered connections directly impacts system durability, with soldered joints generally preferred for their superior leak resistance and strength.

Maintenance and Repair Considerations

Threaded connections offer greater ease of disassembly for maintenance and repairs, allowing plumbers to quickly replace or tighten fittings without specialized tools. Soldered connections create a permanent, leak-proof seal but require heating and cutting for modifications, complicating repairs and increasing labor time. Choosing between the two depends on the frequency of maintenance expected and the accessibility of the piping system.

Cost Analysis: Threaded vs Soldered

Threaded plumbing connections generally incur higher upfront material costs due to the need for specific fittings and sealants, while soldered connections require minimal material expense but demand skilled labor, increasing installation costs. Over time, soldered joints often provide a more durable, leak-resistant solution, potentially reducing maintenance expenses compared to threaded joints, which may loosen and require periodic tightening. Analyzing total costs reveals soldered connections offer better long-term value despite higher labor intensity, whereas threaded connections favor quicker, lower-skill installations with potentially higher lifetime upkeep.

Lifespan and Durability

Threaded connections in plumbing fixtures provide strong mechanical joins that allow easy disassembly but may be prone to loosening and corrosion over time, reducing overall lifespan. Soldered connections offer a permanent, leak-resistant seal with enhanced durability under high pressure and temperature, often extending fixture lifespan significantly. Choosing between these methods depends on intended application, with soldering favored for long-term reliability and threaded connections preferred for maintenance flexibility.

Best Applications for Each Connection Type

Threaded connections are best suited for plumbing systems requiring easy disassembly and maintenance, commonly used in metal pipes such as galvanized steel and brass. Soldered connections provide a leak-proof, permanent bond ideal for copper piping in water supply lines and HVAC systems where long-term durability is essential. Selecting between threaded and soldered connections depends on the pipe material, system pressure, and need for future repairs or modifications.

Threaded Connection vs Soldered Connection Infographic

productdif.com

productdif.com