Ionomer glassware offers excellent impact resistance and flexibility, making it ideal for pet environments where durability is crucial. Silicate glassware, while more brittle, provides superior chemical resistance and clarity, suited for precise laboratory applications. Choosing between ionomer and silicate depends on the balance between toughness and chemical durability required for pet-related uses.

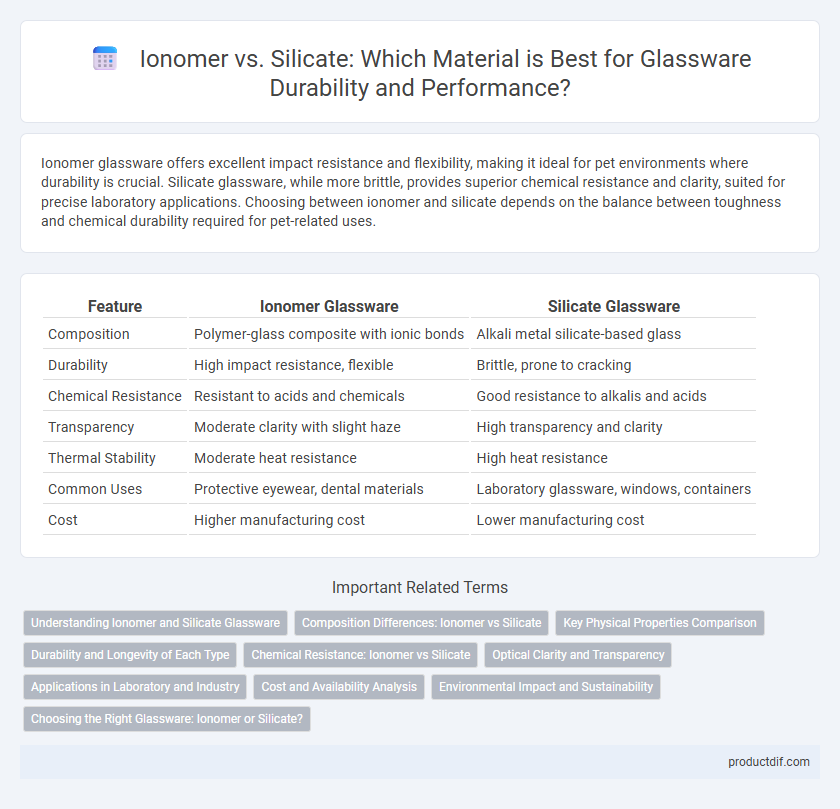

Table of Comparison

| Feature | Ionomer Glassware | Silicate Glassware |

|---|---|---|

| Composition | Polymer-glass composite with ionic bonds | Alkali metal silicate-based glass |

| Durability | High impact resistance, flexible | Brittle, prone to cracking |

| Chemical Resistance | Resistant to acids and chemicals | Good resistance to alkalis and acids |

| Transparency | Moderate clarity with slight haze | High transparency and clarity |

| Thermal Stability | Moderate heat resistance | High heat resistance |

| Common Uses | Protective eyewear, dental materials | Laboratory glassware, windows, containers |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

Understanding Ionomer and Silicate Glassware

Ionomer glassware features ion-exchange properties that enhance durability and chemical resistance, making it suitable for laboratory applications requiring long-term stability. Silicate glassware, composed primarily of silicon dioxide, offers excellent thermal resistance and chemical inertness, ideal for handling high temperatures and aggressive chemicals. Understanding the distinct compositions and properties of ionomer versus silicate glassware helps in selecting the appropriate material for specific scientific and industrial uses.

Composition Differences: Ionomer vs Silicate

Ionomer glassware contains ionic polymer chains that provide enhanced toughness and chemical resistance, whereas silicate glass is primarily composed of silicon dioxide (SiO2) with metal oxides that contribute to its hardness and thermal stability. The unique composition of ionomer materials allows greater flexibility and impact resistance, distinguishing it from the more rigid and brittle structure of silicate glass. Differences in chemical bonding and polymer integration result in varied mechanical properties and applications between ionomer and silicate glassware.

Key Physical Properties Comparison

Ionomer glass exhibits superior chemical durability and enhanced resistance to thermal shock compared to silicate glass, making it ideal for high-impact applications. Silicate glass, primarily composed of silica, offers higher hardness and excellent optical clarity but is more prone to brittleness and thermal stress. The distinct molecular structure of ionomer glass provides improved flexibility and lower water absorption, distinguishing it from traditional silicate variants.

Durability and Longevity of Each Type

Ionomer glassware features enhanced durability due to its strong ionic cross-linking, making it resistant to scratches and impact damage, which extends its longevity in frequent-use settings. Silicate glassware, composed primarily of silicon dioxide, offers excellent thermal stability and chemical resistance but tends to be more brittle and prone to chipping under mechanical stress. The superior strength of ionomer materials ensures longer-lasting performance in everyday use, while silicate glass excels in applications requiring high resistance to heat and chemicals.

Chemical Resistance: Ionomer vs Silicate

Ionomer glassware exhibits superior chemical resistance to acids and bases due to its ionic polymer matrix, reducing corrosion and degradation over time. Silicate glassware, primarily composed of silica, offers excellent resistance to most chemicals but is vulnerable to strong alkaline solutions, leading to etching and surface damage. Choosing between ionomer and silicate glassware depends on the specific chemical environment and exposure frequency to maintain durability and performance.

Optical Clarity and Transparency

Ionomer glassware exhibits superior optical clarity and higher transparency compared to silicate glass due to its enhanced light transmission properties and reduced surface imperfections. Silicate glass, while durable, often presents minor inclusions and micro-cracks that scatter light, decreasing overall transparency and clarity. Advanced ionomer compositions achieve a smoother surface finish, resulting in minimal light distortion and exceptional visual purity in glassware applications.

Applications in Laboratory and Industry

Ionomer glassware offers superior chemical resistance and durability, making it ideal for laboratory applications involving strong acids and bases, as well as industrial processes requiring frequent sterilization. Silicate glassware, known for its excellent thermal resistance and optical clarity, is commonly used in precision laboratory measurements and pharmaceutical manufacturing. Both materials provide unique advantages, with ionomer glass excelling in harsh chemical environments and silicate glass preferred for high-temperature and optical applications.

Cost and Availability Analysis

Ionomer glassware generally offers a cost-effective option due to its lower production expenses and higher availability, making it suitable for budget-conscious consumers. Silicate glass, while often more expensive because of its complex manufacturing process and premium raw materials, provides greater durability and resistance to thermal shock. Market availability of silicate glassware is more limited compared to ionomer, impacting procurement timelines and overall cost-efficiency.

Environmental Impact and Sustainability

Ionomer glassware offers enhanced recyclability compared to traditional silicate glass due to its unique polymer-metal ion structure, which allows for lower energy consumption during manufacturing and easier material recovery. Silicate glass, while durable, requires high-temperature melting processes that contribute to greater carbon emissions and are less efficient in closed-loop recycling systems. Choosing ionomer glassware supports sustainability by reducing environmental impact through decreased energy use and improved lifecycle management.

Choosing the Right Glassware: Ionomer or Silicate?

Choosing the right glassware involves understanding the distinct properties of ionomer and silicate materials. Ionomer glassware offers enhanced chemical resistance and durability, making it ideal for handling acidic or corrosive substances, while silicate glassware provides superior thermal stability and clarity ideal for precise laboratory observations. Selecting between ionomer and silicate depends on the specific application requirements such as chemical compatibility, thermal conditions, and transparency needs.

Ionomer vs Silicate Infographic

productdif.com

productdif.com