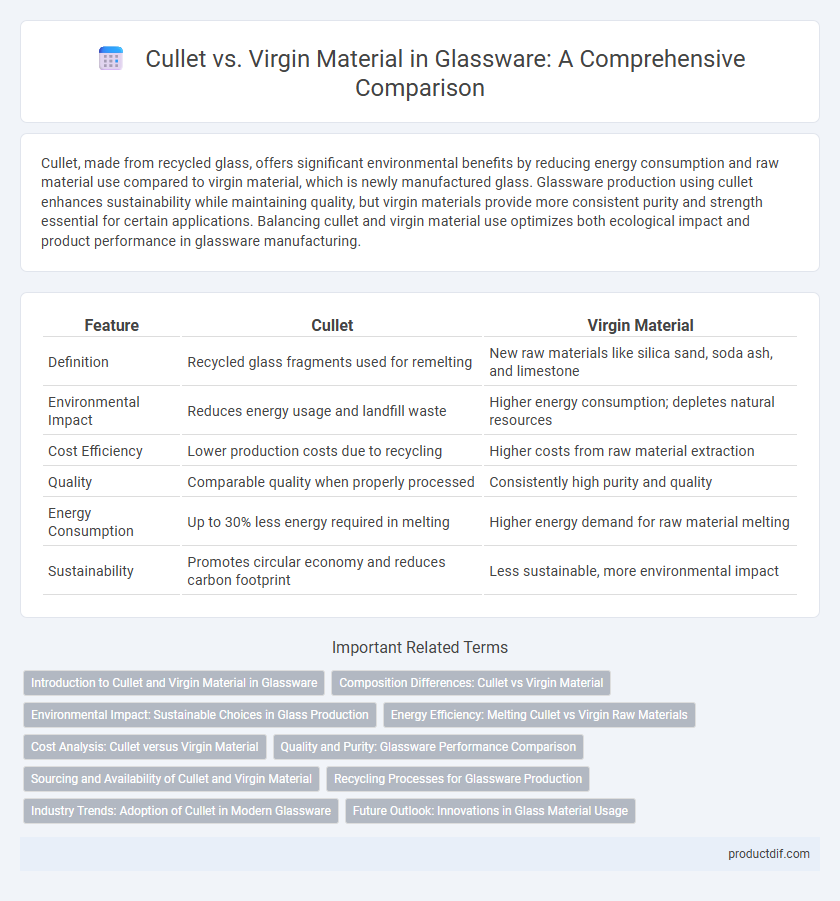

Cullet, made from recycled glass, offers significant environmental benefits by reducing energy consumption and raw material use compared to virgin material, which is newly manufactured glass. Glassware production using cullet enhances sustainability while maintaining quality, but virgin materials provide more consistent purity and strength essential for certain applications. Balancing cullet and virgin material use optimizes both ecological impact and product performance in glassware manufacturing.

Table of Comparison

| Feature | Cullet | Virgin Material |

|---|---|---|

| Definition | Recycled glass fragments used for remelting | New raw materials like silica sand, soda ash, and limestone |

| Environmental Impact | Reduces energy usage and landfill waste | Higher energy consumption; depletes natural resources |

| Cost Efficiency | Lower production costs due to recycling | Higher costs from raw material extraction |

| Quality | Comparable quality when properly processed | Consistently high purity and quality |

| Energy Consumption | Up to 30% less energy required in melting | Higher energy demand for raw material melting |

| Sustainability | Promotes circular economy and reduces carbon footprint | Less sustainable, more environmental impact |

Introduction to Cullet and Virgin Material in Glassware

Cullet refers to recycled glass fragments used in glassmaking, offering a sustainable alternative to virgin material, which consists of raw, unprocessed sand, soda ash, and limestone. Incorporating cullet reduces energy consumption by melting faster than virgin materials, lowering furnace temperatures and decreasing carbon emissions in the production process. The balance between cullet and virgin material significantly impacts glass quality, production efficiency, and environmental footprint in the glassware industry.

Composition Differences: Cullet vs Virgin Material

Cullet consists of recycled glass fragments containing varying amounts of impurities and previously melted glass, which alters its silica, soda ash, and lime proportions compared to virgin material. Virgin glass material is made from raw, pure silica sand, sodium carbonate, and limestone in precise ratios, ensuring consistent chemical composition and optimal melting properties. The presence of contaminants in cullet can affect the homogeneity and quality of the final glass product, requiring adjustments in batch formulation to achieve desired glass characteristics.

Environmental Impact: Sustainable Choices in Glass Production

Cullet, or recycled glass, significantly reduces energy consumption and raw material extraction compared to virgin materials in glass production. Utilizing cullet lowers carbon emissions by up to 30%, making it a vital component for sustainable manufacturing practices. Producers increasingly favor cullet to minimize environmental impact while maintaining high-quality glass products.

Energy Efficiency: Melting Cullet vs Virgin Raw Materials

Melting cullet requires significantly less energy compared to processing virgin raw materials, as cullet melts at a lower temperature due to its already processed glass structure. Using cullet reduces fuel consumption by up to 25-30%, leading to lower carbon emissions and cost savings in glass production. Incorporating a high percentage of cullet into the batch mix enhances overall energy efficiency and sustainability in manufacturing glassware.

Cost Analysis: Cullet versus Virgin Material

Cullet, or recycled glass, significantly reduces production costs compared to virgin material due to lower energy consumption in melting processes and decreased raw material expenses. Utilizing cullet can lower furnace energy use by up to 30%, resulting in substantial savings in fuel costs and greenhouse gas emissions. In contrast, virgin materials demand higher extraction and processing costs, increasing overall production expenditures and environmental impact.

Quality and Purity: Glassware Performance Comparison

Cullet, recycled glass material, often contains impurities that can affect the quality and clarity of glassware, whereas virgin material offers superior purity resulting in consistently higher performance and durability. Glassware produced from virgin material typically exhibits better strength, enhanced optical properties, and greater resistance to thermal shock. Utilizing virgin raw materials ensures premium quality outcomes essential for precision glassware in scientific and luxury applications.

Sourcing and Availability of Cullet and Virgin Material

Cullet, sourced primarily from recycled glass collections and post-consumer waste, offers a sustainable and increasingly available raw material for glassware production due to growing recycling programs worldwide. Virgin material, derived from mined silica sand, soda ash, and limestone, depends on finite natural resources and mining operations, leading to variable availability influenced by geopolitical and environmental factors. The accessibility of cullet fluctuates with regional recycling infrastructure efficiency, while virgin material supply remains subject to extraction costs and regulatory constraints.

Recycling Processes for Glassware Production

Cullet, or recycled glass, significantly reduces energy consumption and raw material use in glassware production compared to virgin materials, which require intensive mining of silica sand and other resources. Incorporating cullet in the furnace lowers melting temperatures and greenhouse gas emissions, enhancing sustainability in recycling processes. High-quality cullet recycling involves sorting, cleaning, and crushing to remove contaminants, ensuring seamless integration with virgin materials for efficient, eco-friendly glassware manufacturing.

Industry Trends: Adoption of Cullet in Modern Glassware

The glassware industry increasingly prioritizes cullet due to its lower energy consumption and reduced carbon footprint compared to virgin materials. Modern manufacturing processes utilize up to 90% recycled cullet, enhancing sustainability and cost-efficiency in mass production. Advances in cullet sorting and cleaning technologies enable higher-quality glass products, driving widespread adoption within eco-conscious markets.

Future Outlook: Innovations in Glass Material Usage

Future innovations in glass material usage prioritize increased recycling of cullet to reduce environmental impact and lower production costs. Advancements in refining technologies enable higher purity cullet incorporation without compromising glass quality, supporting sustainable manufacturing practices. Emerging bio-based additives and nanomaterials integrated with virgin glass components promise enhanced durability, energy efficiency, and novel functionalities in glassware products.

Cullet vs Virgin material Infographic

productdif.com

productdif.com