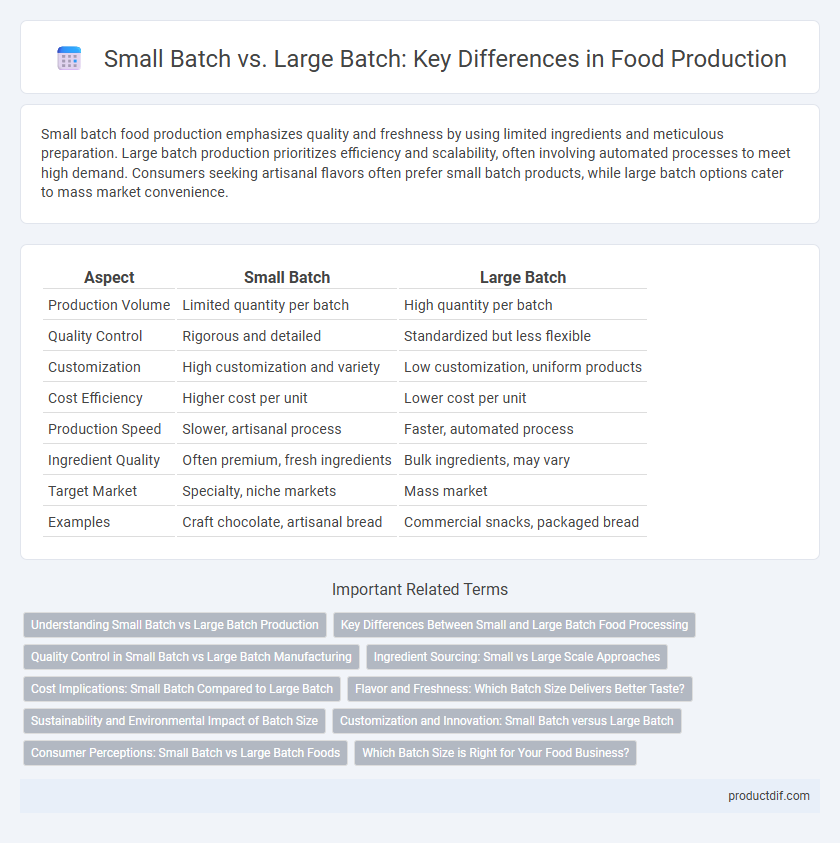

Small batch food production emphasizes quality and freshness by using limited ingredients and meticulous preparation. Large batch production prioritizes efficiency and scalability, often involving automated processes to meet high demand. Consumers seeking artisanal flavors often prefer small batch products, while large batch options cater to mass market convenience.

Table of Comparison

| Aspect | Small Batch | Large Batch |

|---|---|---|

| Production Volume | Limited quantity per batch | High quantity per batch |

| Quality Control | Rigorous and detailed | Standardized but less flexible |

| Customization | High customization and variety | Low customization, uniform products |

| Cost Efficiency | Higher cost per unit | Lower cost per unit |

| Production Speed | Slower, artisanal process | Faster, automated process |

| Ingredient Quality | Often premium, fresh ingredients | Bulk ingredients, may vary |

| Target Market | Specialty, niche markets | Mass market |

| Examples | Craft chocolate, artisanal bread | Commercial snacks, packaged bread |

Understanding Small Batch vs Large Batch Production

Small batch production involves crafting limited quantities of food products, emphasizing quality control, unique flavors, and artisanal techniques. Large batch production prioritizes volume and efficiency, using standardized processes to meet high consumer demand with consistent taste and texture. Understanding the differences informs choices in food manufacturing strategies, product customization, and market positioning.

Key Differences Between Small and Large Batch Food Processing

Small batch food processing emphasizes quality control, artisanal techniques, and customization, resulting in unique flavors and fresher ingredients. Large batch food processing prioritizes efficiency, scalability, and cost-effectiveness, often using automated machinery to produce consistent products quickly. Key differences include production volume, flexibility in recipe adjustments, and the balance between artisanal craftsmanship versus industrial standardization.

Quality Control in Small Batch vs Large Batch Manufacturing

Quality control in small batch manufacturing allows for meticulous monitoring at every production stage, ensuring higher consistency and product integrity. Large batch manufacturing faces challenges in maintaining uniform quality due to the sheer volume and complexity of processes, often requiring advanced automation and statistical quality control methods. Small batch production typically results in fewer defects and greater flexibility to implement quality improvements quickly.

Ingredient Sourcing: Small vs Large Scale Approaches

Small batch food producers prioritize sourcing high-quality, often local and organic ingredients to ensure freshness and unique flavor profiles, supporting sustainable farming practices and artisanal suppliers. Large batch operations rely on bulk purchasing from large-scale suppliers to maintain cost efficiency and consistent ingredient availability, often sourcing from industrial-scale farms and global distributors. The distinct sourcing methods reflect differing priorities: quality and traceability for small batches, versus volume and price stability for large-scale production.

Cost Implications: Small Batch Compared to Large Batch

Small batch production incurs higher per-unit costs due to limited economies of scale and increased labor intensity, leading to greater expenses in raw materials and packaging. Large batch production benefits from bulk purchasing and streamlined processes, resulting in significantly lower costs per unit. However, small batches allow for pricing flexibility and premium positioning, partially offsetting higher costs through targeted markets.

Flavor and Freshness: Which Batch Size Delivers Better Taste?

Small batch cooking preserves flavor and freshness by minimizing exposure to air and reducing storage time, which helps maintain the integrity of ingredients and enhances taste complexity. Large batch production often sacrifices subtle flavor nuances due to extended holding times and repetitive processing, leading to diminished freshness and uniformity. Choosing small batch methods aligns with superior flavor profiles and peak freshness, delivering a more vibrant and enjoyable culinary experience.

Sustainability and Environmental Impact of Batch Size

Small batch production minimizes waste by using precise ingredient quantities, reducing the carbon footprint associated with overproduction and spoilage. Large batch production, while efficient in energy use per unit, often leads to excess food waste and resource consumption if demand forecasts are inaccurate. Sustainable food systems benefit from small batches that support local sourcing, lower transportation emissions, and promote more responsible ingredient usage.

Customization and Innovation: Small Batch versus Large Batch

Small batch production enables greater customization and innovation by allowing chefs and producers to experiment with unique ingredients and tailor recipes to specific tastes. In contrast, large batch production prioritizes consistency and efficiency, often limiting the ability to modify formulas or introduce new variations quickly. This flexibility in small batches fosters creative culinary development and niche market appeal.

Consumer Perceptions: Small Batch vs Large Batch Foods

Consumers often perceive small batch foods as higher quality, artisanal, and more flavorful due to limited production and attention to detail. Large batch foods, while more affordable and widely available, may be viewed as mass-produced and lacking in uniqueness. This perception influences purchasing decisions, with many consumers willing to pay a premium for small batch products that emphasize craftsmanship and authenticity.

Which Batch Size is Right for Your Food Business?

Small batch production offers greater control over quality, allowing food businesses to experiment with unique recipes and cater to niche markets, ideal for startups and artisanal brands. Large batch production maximizes efficiency and reduces per-unit costs through economies of scale, making it suitable for established companies with high demand and standardized products. Choosing the right batch size depends on factors like production volume, target market, product consistency, and capital investment.

Small batch vs Large batch Infographic

productdif.com

productdif.com