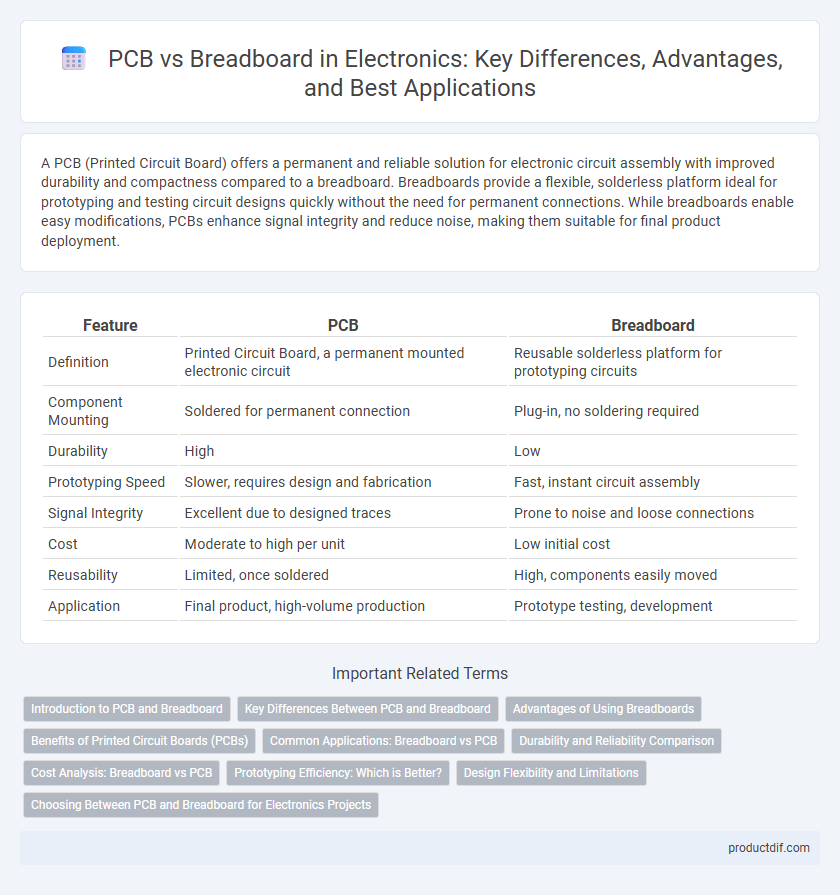

A PCB (Printed Circuit Board) offers a permanent and reliable solution for electronic circuit assembly with improved durability and compactness compared to a breadboard. Breadboards provide a flexible, solderless platform ideal for prototyping and testing circuit designs quickly without the need for permanent connections. While breadboards enable easy modifications, PCBs enhance signal integrity and reduce noise, making them suitable for final product deployment.

Table of Comparison

| Feature | PCB | Breadboard |

|---|---|---|

| Definition | Printed Circuit Board, a permanent mounted electronic circuit | Reusable solderless platform for prototyping circuits |

| Component Mounting | Soldered for permanent connection | Plug-in, no soldering required |

| Durability | High | Low |

| Prototyping Speed | Slower, requires design and fabrication | Fast, instant circuit assembly |

| Signal Integrity | Excellent due to designed traces | Prone to noise and loose connections |

| Cost | Moderate to high per unit | Low initial cost |

| Reusability | Limited, once soldered | High, components easily moved |

| Application | Final product, high-volume production | Prototype testing, development |

Introduction to PCB and Breadboard

Printed Circuit Boards (PCBs) are rigid or flexible boards used to mechanically support and electrically connect electronic components through etched copper pathways, offering durability and compact design for permanent circuits. Breadboards provide a reusable platform with a grid of interconnected sockets that simplify prototyping by allowing quick insertion and removal of components without soldering. Both tools serve essential roles in electronics development, with PCBs suited for finalized projects and breadboards ideal for experimental testing and circuit design iterations.

Key Differences Between PCB and Breadboard

Printed Circuit Boards (PCBs) offer permanent, reliable electrical connections with precise component placement, whereas breadboards provide a reusable platform for quick prototyping without soldering. PCBs support complex, high-density circuits with optimized signal integrity, while breadboards are limited to simpler, low-frequency designs due to potential contact resistance and signal noise. The choice between PCB and breadboard hinges on the project stage: breadboards excel in initial testing and design iteration, whereas PCBs are ideal for finalized, commercial-grade electronics.

Advantages of Using Breadboards

Breadboards offer rapid prototyping capabilities, allowing engineers to quickly test and modify circuits without soldering, which saves significant development time. Their reusable and modular nature supports easy component insertion and removal, facilitating iterative design and troubleshooting. Breadboards also provide a cost-effective solution for experimenting with low-frequency electronics before committing to a printed circuit board (PCB) layout.

Benefits of Printed Circuit Boards (PCBs)

Printed Circuit Boards (PCBs) offer superior reliability and durability by providing sturdy, permanent electrical connections compared to breadboards, which use temporary contact points prone to disconnects. PCBs enable compact, complex circuit designs with precise component placement and consistent signal integrity, essential for high-frequency and high-performance electronics. Mass production of PCBs ensures uniformity and efficiency, reducing assembly errors and improving overall product quality in professional electronic manufacturing.

Common Applications: Breadboard vs PCB

Breadboards are commonly used for prototyping and testing electronic circuits due to their reusable and solderless design, allowing quick modifications and troubleshooting. Printed Circuit Boards (PCBs) are preferred for final products and commercial electronics, offering durability, compactness, and reliable electrical connections through permanent soldered components. While breadboards excel in education and experimentation, PCBs dominate in mass production and high-frequency applications requiring signal integrity.

Durability and Reliability Comparison

Printed circuit boards (PCBs) offer superior durability compared to breadboards due to their rigid fiberglass substrate and soldered connections, which resist physical wear and environmental factors. Breadboards, designed for prototyping, use spring clips and loose wires, making them susceptible to intermittent connections and mechanical stress over time. Reliability in long-term electronic projects favors PCBs as they maintain consistent electrical pathways and prevent signal interference common in breadboard setups.

Cost Analysis: Breadboard vs PCB

Breadboards offer a cost-effective solution for prototyping with no need for manufacturing expenses, making them ideal for small-scale or iterative design testing. Printed Circuit Boards (PCBs), while involving higher upfront costs due to fabrication and design software fees, provide long-term savings through improved reliability, compactness, and reduced assembly time in mass production. Evaluating total cost of ownership, PCB investment becomes economical for larger volumes despite the initial expense, whereas breadboards excel in flexible, low-cost experimentation.

Prototyping Efficiency: Which is Better?

PCB prototyping offers superior reliability and consistent electrical connections, reducing errors commonly encountered with breadboards. Unlike breadboards, PCBs enable compact circuit layouts and facilitate automated assembly for faster iteration. Breadboards provide quick setup and easy component swapping but often suffer from loose connections and signal interference, making PCBs the preferred choice for efficient and scalable prototyping.

Design Flexibility and Limitations

PCB offers superior design flexibility with custom layouts and compact component placement, enabling complex circuits and high-frequency applications. Breadboards allow quick prototyping and easy modifications but suffer from limitations such as loose connections, signal interference, and lack of durability. While PCBs ensure reliability and scalability in final designs, breadboards remain ideal for initial testing and simple circuit experiments.

Choosing Between PCB and Breadboard for Electronics Projects

Choosing between a PCB and a breadboard depends on project requirements, durability, and complexity. PCBs offer long-term reliability, compact design, and professional-grade connections, making them ideal for finished products and high-frequency circuits. Breadboards provide flexibility and ease of prototyping without soldering, perfect for experimental circuits and quick testing.

PCB vs Breadboard Infographic

productdif.com

productdif.com