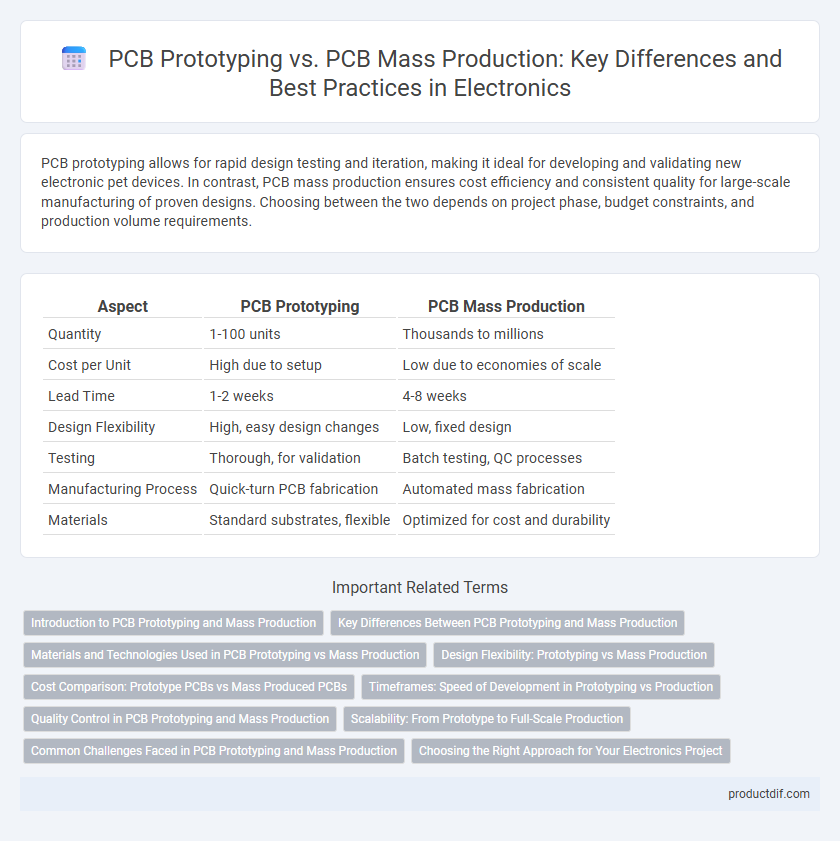

PCB prototyping allows for rapid design testing and iteration, making it ideal for developing and validating new electronic pet devices. In contrast, PCB mass production ensures cost efficiency and consistent quality for large-scale manufacturing of proven designs. Choosing between the two depends on project phase, budget constraints, and production volume requirements.

Table of Comparison

| Aspect | PCB Prototyping | PCB Mass Production |

|---|---|---|

| Quantity | 1-100 units | Thousands to millions |

| Cost per Unit | High due to setup | Low due to economies of scale |

| Lead Time | 1-2 weeks | 4-8 weeks |

| Design Flexibility | High, easy design changes | Low, fixed design |

| Testing | Thorough, for validation | Batch testing, QC processes |

| Manufacturing Process | Quick-turn PCB fabrication | Automated mass fabrication |

| Materials | Standard substrates, flexible | Optimized for cost and durability |

Introduction to PCB Prototyping and Mass Production

PCB prototyping involves creating a small number of printed circuit boards to validate design functionality, enabling quick adjustments and error detection before full-scale manufacturing. Mass production of PCBs focuses on efficient, high-volume fabrication using automated assembly lines and stringent quality controls to ensure consistency and cost-effectiveness. Choosing between prototyping and mass production depends on project requirements, timelines, and budget considerations in electronic product development.

Key Differences Between PCB Prototyping and Mass Production

PCB prototyping involves creating small batches of printed circuit boards to validate design and functionality, typically emphasizing flexibility and rapid iteration, whereas PCB mass production focuses on high-volume manufacturing ensuring cost efficiency and consistent quality. Prototyping uses simpler fabrication methods with quick turnaround times, while mass production employs automated processes and stringent quality control to meet scalability demands. Material selection and assembly techniques also differ, with prototypes often using off-the-shelf components and mass production requiring optimized sourcing for supply chain efficiency.

Materials and Technologies Used in PCB Prototyping vs Mass Production

PCB prototyping typically utilizes flexible and cost-effective materials like FR-4 or single-layer copper-clad laminates to enable rapid iteration with technologies such as CNC milling and quick-turn photolithography. Mass production employs advanced materials including multi-layer FR-4 with high Tg values, heavy copper, and specialized substrate laminates like Rogers for enhanced performance and reliability, combined with technologies like automated surface-mount technology (SMT) assembly and high-precision laser drilling. These material and technological differences ensure prototypes are adaptable and economically viable, while mass production guarantees durability, signal integrity, and scalability.

Design Flexibility: Prototyping vs Mass Production

PCB prototyping offers exceptional design flexibility, allowing engineers to quickly iterate and test various circuit configurations without committing to large production runs. In contrast, PCB mass production involves fixed designs optimized for high-volume manufacturing, where changes become costly and time-consuming. This difference in design adaptability makes prototyping essential for refining complex electronics before scaling to mass production.

Cost Comparison: Prototype PCBs vs Mass Produced PCBs

Prototype PCBs typically incur higher costs per unit due to small batch sizes, custom designs, and expedited manufacturing processes, with prices ranging from $10 to $100 per board depending on complexity. In contrast, mass-produced PCBs benefit from economies of scale, significantly reducing costs to as low as $0.10 to $5 per unit for large volume orders exceeding 10,000 boards. Tooling and setup fees are amortized over large quantities in mass production, making it the most cost-effective choice for high-volume electronic product manufacturing.

Timeframes: Speed of Development in Prototyping vs Production

PCB prototyping enables rapid design validation with turnaround times typically ranging from a few hours to several days, accelerating early-stage development and troubleshooting. In contrast, PCB mass production involves longer lead times due to batch processing, quality assurance, and logistics, often taking several weeks to complete large-scale orders. Faster prototyping cycles facilitate agile iteration, while production emphasizes scalability and consistency over speed.

Quality Control in PCB Prototyping and Mass Production

Quality control in PCB prototyping emphasizes rapid identification of design flaws and material defects through thorough inspections and electrical testing to ensure functionality before scaling. In contrast, PCB mass production integrates automated optical inspection (AOI), solder paste inspection (SPI), and functional testing to maintain consistency and minimize defects across large volumes. Effective quality control protocols in both stages reduce costly rework and enhance overall product reliability.

Scalability: From Prototype to Full-Scale Production

PCB prototyping allows for quick design validation and functional testing with low initial investment, enabling efficient iterations before committing to larger volumes. Mass production of PCBs leverages automated assembly lines and advanced fabrication techniques to achieve high scalability, consistent quality, and cost-efficiency per unit at large volumes. Transitioning from prototype to full-scale production requires careful design optimization and process standardization to maintain signal integrity and manufacturing yield.

Common Challenges Faced in PCB Prototyping and Mass Production

PCB prototyping often encounters challenges such as design errors, limited material options, and long iteration cycles that can delay product development. In mass production, issues like maintaining consistent quality across large batches, managing high-volume assembly costs, and ensuring supply chain reliability are prevalent. Both processes require rigorous testing and quality control to minimize defects and achieve optimal functionality in electronic devices.

Choosing the Right Approach for Your Electronics Project

PCB prototyping allows for rapid iteration and design validation, making it ideal for testing new electronics concepts with a lower initial cost and shorter turnaround times. Mass production of PCBs ensures consistent quality, scalability, and cost-efficiency for large-volume orders, leveraging advanced manufacturing processes and automated assembly lines. Selecting the appropriate approach depends on project requirements such as production volume, budget constraints, timeline, and design complexity to optimize performance and cost.

PCB prototyping vs PCB mass production Infographic

productdif.com

productdif.com