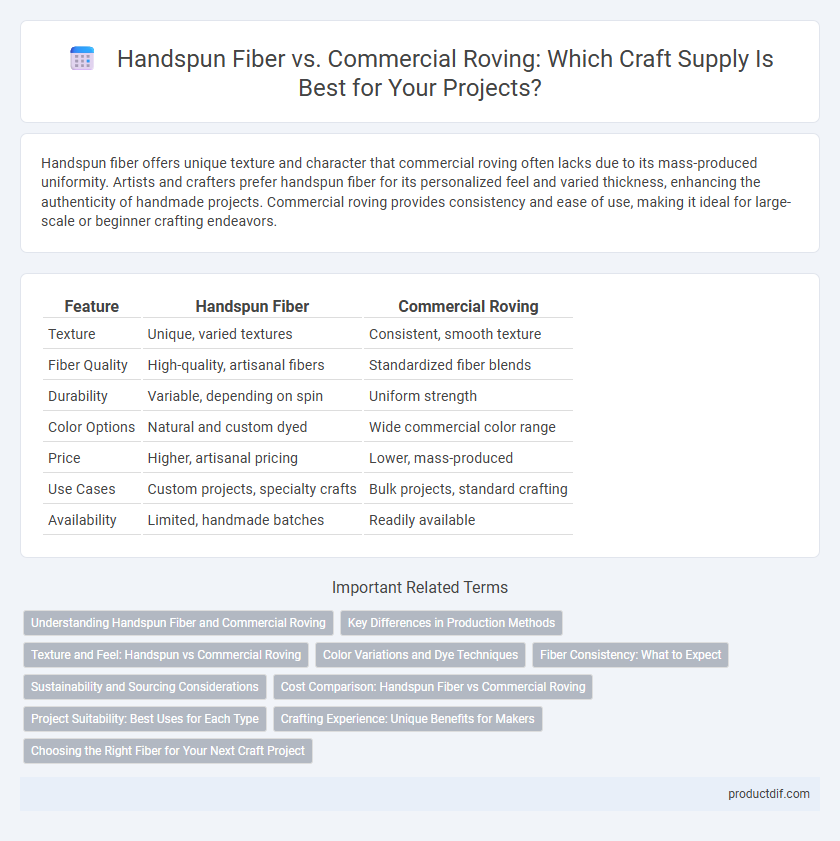

Handspun fiber offers unique texture and character that commercial roving often lacks due to its mass-produced uniformity. Artists and crafters prefer handspun fiber for its personalized feel and varied thickness, enhancing the authenticity of handmade projects. Commercial roving provides consistency and ease of use, making it ideal for large-scale or beginner crafting endeavors.

Table of Comparison

| Feature | Handspun Fiber | Commercial Roving |

|---|---|---|

| Texture | Unique, varied textures | Consistent, smooth texture |

| Fiber Quality | High-quality, artisanal fibers | Standardized fiber blends |

| Durability | Variable, depending on spin | Uniform strength |

| Color Options | Natural and custom dyed | Wide commercial color range |

| Price | Higher, artisanal pricing | Lower, mass-produced |

| Use Cases | Custom projects, specialty crafts | Bulk projects, standard crafting |

| Availability | Limited, handmade batches | Readily available |

Understanding Handspun Fiber and Commercial Roving

Handspun fiber offers unique texture and character due to its artisanal spinning process, resulting in varied thickness and organic imperfections that add depth to finished textile projects. Commercial roving, produced through mechanized and consistent methods, provides uniformity in fiber diameter and twist, making it ideal for predictable, large-scale crafting or machine use. Understanding these differences allows crafters to select materials that best suit their project's aesthetic and functional requirements.

Key Differences in Production Methods

Handspun fiber is crafted by manually twisting fibers, resulting in a unique texture and varying thickness that reflects individual artisan techniques. Commercial roving is produced using mechanized processes that ensure uniformity, consistent thickness, and large-scale volume suited for mass production. These production method differences directly impact the fiber's texture, durability, and suitability for specific craft projects.

Texture and Feel: Handspun vs Commercial Roving

Handspun fiber offers a unique texture characterized by subtle irregularities and a soft, airy feel that enhances tactile warmth and individuality in finished crafts. Commercial roving, produced in large batches, presents a more uniform and smooth texture, providing consistency but lacking the organic variation found in handspun fibers. The distinct tactile differences between handspun and commercial roving influence the overall sensory experience and aesthetic quality of handmade textile projects.

Color Variations and Dye Techniques

Handspun fiber offers unique color variations due to its manual dyeing process, which often results in subtle gradients and rich, unpredictable hues that enhance the texture and depth of finished crafts. Commercial roving typically features more uniform, consistent colors achieved through industrial dye techniques, providing a reliable palette for large-scale or repetitive projects. Artisans seeking distinct, one-of-a-kind color effects often prefer handspun fiber, while crafters valuing consistency and color repeatability tend to choose commercial roving.

Fiber Consistency: What to Expect

Handspun fiber often exhibits natural variations in texture and thickness due to the manual spinning process, resulting in unique, one-of-a-kind yarns with subtle inconsistencies. Commercial roving, produced by machines, provides a more uniform fiber consistency, ideal for projects requiring smooth, even stitches and predictable results. Understanding these differences helps crafters select the appropriate fiber type based on the desired texture and pattern precision in their finished work.

Sustainability and Sourcing Considerations

Handspun fiber often originates from small-scale, sustainable farms emphasizing ethical animal treatment and regenerative practices, contrasting with commercial roving typically produced in large factories with variable environmental standards. The artisanal sourcing of handspun fiber supports local economies and reduces carbon footprints due to limited transportation, while commercial roving frequently relies on synthetic blends and mass production methods that may increase environmental impact. Choosing handspun fiber promotes sustainability through traceable, natural materials and eco-conscious production, making it a preferred option for environmentally minded crafters.

Cost Comparison: Handspun Fiber vs Commercial Roving

Handspun fiber often costs more per ounce than commercial roving due to the labor-intensive spinning process and the artisan quality involved. Commercial roving is mass-produced, lowering the price through economies of scale and making it a more budget-friendly option for bulk fiber needs. When comparing cost efficiency, handspun fiber represents a premium investment for unique texture and customization, whereas commercial roving offers greater affordability for larger projects.

Project Suitability: Best Uses for Each Type

Handspun fiber offers unique texture and variation, making it ideal for artisanal projects such as hand-knitted scarves, textured blankets, and custom felting designs where individuality is prized. Commercial roving provides uniform thickness and is best suited for machine spinning, large-scale weaving, and felting projects requiring consistency and durability. Choosing between the two depends on whether the project demands handcrafted character or standardized performance.

Crafting Experience: Unique Benefits for Makers

Handspun fiber offers a distinctive tactile quality and personalized character, enhancing the crafting experience with its irregular textures and color variations that inspire creativity. Commercial roving provides consistency and uniformity, making it ideal for projects requiring even thickness and smooth finishes. Makers benefit from handspun fiber's artisanal uniqueness, while commercial roving supports efficiency and predictability in craft production.

Choosing the Right Fiber for Your Next Craft Project

Handspun fiber offers unique texture and character ideal for artisanal knitting or weaving projects, providing unmatched softness and customization. Commercial roving delivers consistent thickness and color, perfect for beginners or large-scale production crafting. Evaluating the project's needs for durability, appearance, and tactile qualities guides the choice between handspun fiber and commercial roving.

Handspun fiber vs Commercial roving Infographic

productdif.com

productdif.com