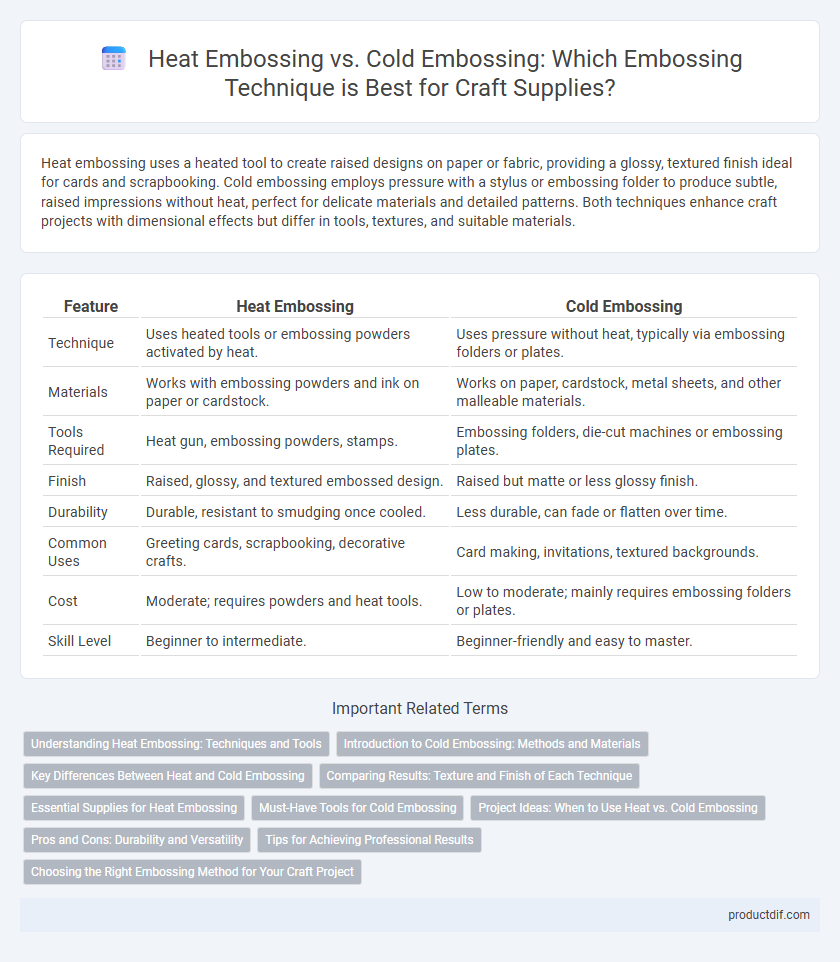

Heat embossing uses a heated tool to create raised designs on paper or fabric, providing a glossy, textured finish ideal for cards and scrapbooking. Cold embossing employs pressure with a stylus or embossing folder to produce subtle, raised impressions without heat, perfect for delicate materials and detailed patterns. Both techniques enhance craft projects with dimensional effects but differ in tools, textures, and suitable materials.

Table of Comparison

| Feature | Heat Embossing | Cold Embossing |

|---|---|---|

| Technique | Uses heated tools or embossing powders activated by heat. | Uses pressure without heat, typically via embossing folders or plates. |

| Materials | Works with embossing powders and ink on paper or cardstock. | Works on paper, cardstock, metal sheets, and other malleable materials. |

| Tools Required | Heat gun, embossing powders, stamps. | Embossing folders, die-cut machines or embossing plates. |

| Finish | Raised, glossy, and textured embossed design. | Raised but matte or less glossy finish. |

| Durability | Durable, resistant to smudging once cooled. | Less durable, can fade or flatten over time. |

| Common Uses | Greeting cards, scrapbooking, decorative crafts. | Card making, invitations, textured backgrounds. |

| Cost | Moderate; requires powders and heat tools. | Low to moderate; mainly requires embossing folders or plates. |

| Skill Level | Beginner to intermediate. | Beginner-friendly and easy to master. |

Understanding Heat Embossing: Techniques and Tools

Heat embossing utilizes a heat source, such as a heat gun, to melt embossing powders that adhere to inked surfaces, creating raised, glossy designs ideal for cards and paper crafts. Key tools include embossing powders, heat guns, embossing pens, and stamps designed for oil-based or embossing ink, which maintain powder adhesion before heating. Mastery of temperature control and timing ensures crisp, bubble-free textures, enhancing the visual depth and tactile appeal of craft projects.

Introduction to Cold Embossing: Methods and Materials

Cold embossing involves creating raised designs on paper, cardstock, or thin metal sheets without heat, using pressure to imprint patterns. Common methods include using embossing folders with a manual or electronic die-cutting machine, or dry embossing with stylus tools on a stencil to shape the surface intricately. Popular materials for cold embossing are heavyweight cardstock, vellum, and foils that respond well to pressure, allowing crafters to achieve detailed, textured effects without the risk of heat damage.

Key Differences Between Heat and Cold Embossing

Heat embossing uses a heat source to melt embossing powder, creating raised, glossy patterns on paper or cardstock, while cold embossing relies on pressure to imprint designs without heat, often using embossing folders or styluses. Heat embossing offers vibrant, durable finishes ideal for cards and scrapbooking, whereas cold embossing provides subtle, textured effects suited for paper crafts and delicate projects. The key differences lie in the use of heat versus pressure, the final texture and appearance, and the tools required for each technique.

Comparing Results: Texture and Finish of Each Technique

Heat embossing creates a raised, glossy texture with sharp, well-defined edges, ideal for adding a polished, professional finish to paper and cardstock. Cold embossing produces a subtle, debossed effect with matte, softer contours that enhance tactile interest without altering the surface color. Comparing results, heat embossing delivers vibrant, durable designs perfect for intricate details, while cold embossing offers elegant, understated texture suited for layering and dimensional effects.

Essential Supplies for Heat Embossing

Heat embossing requires essential supplies such as embossing powders, a heat gun, and a watermark ink pad to create raised, glossy designs on paper or fabric. Unlike cold embossing, which relies on styluses or embossing folders without heat, heat embossing enhances detail and texture with durable, vibrant finishes. High-quality embossing powders and a reliable heat tool ensure professional results and prevent scorching or uneven melting.

Must-Have Tools for Cold Embossing

Cold embossing requires essential tools such as embossing folders, manual or electric embossing machines, and smooth, sturdy cardstock to achieve precise designs. Unlike heat embossing, which needs embossing powders and heat guns, cold embossing relies heavily on quality embossing folders and a reliable embossing machine like the Sizzix or Cuttlebug. For detailed textures and raised patterns, must-have accessories include silicone mats and stylus pens for added control during the embossing process.

Project Ideas: When to Use Heat vs. Cold Embossing

Heat embossing is ideal for projects requiring raised, glossy designs on paper, such as greeting cards and invitations, as it uses heated embossing powders for a durable, professional finish. Cold embossing suits projects involving metal, leather, or thicker cardstock where texture and dimensional patterns are desired without heat, perfect for scrapbooking and mixed media crafts. Choose heat embossing for vibrant, embossed text or images, while cold embossing excels in adding subtler, tactile details to various craft materials.

Pros and Cons: Durability and Versatility

Heat embossing offers superior durability due to its ability to create raised, resin-like textures that resist wear and fading over time. Cold embossing provides greater versatility by allowing detailed, intricate designs on delicate materials without heat damage, though it may lack long-term resilience in high-friction use. Choosing between heat and cold embossing depends on prioritizing either lasting durability or adaptable application on various craft surfaces.

Tips for Achieving Professional Results

Heat embossing requires a steady hand and quick application of embossing powder to prevent clumping, combined with a heat gun held at an optimal distance to avoid scorching the paper. Cold embossing benefits from using high-quality embossing folders and applying consistent, even pressure with a manual or electronic die-cut machine to ensure clean, crisp impressions. For both methods, selecting the right paper thickness and practicing on scrap materials significantly enhances the clarity and durability of the embossed design.

Choosing the Right Embossing Method for Your Craft Project

Heat embossing offers a glossy, raised finish ideal for detailed designs on paper, using embossing powders and a heat gun to create a durable texture. Cold embossing involves pressing or stamping without heat, perfect for thicker materials like metal or leather, producing subtle, textured effects that preserve the material's integrity. Selecting the right method depends on the project's material, desired texture, and durability requirements.

Heat embossing vs Cold embossing Infographic

productdif.com

productdif.com