Bottle conditioning naturally carbonates beverages through yeast fermentation inside the sealed bottle, creating a finer, more complex carbonation profile and enhancing flavor development. Force carbonation injects CO2 directly into the beverage, allowing for faster carbonation control and consistency, making it ideal for large-scale or time-sensitive production. Each method impacts taste, carbonation quality, and production timelines differently, influencing the final beverage experience.

Table of Comparison

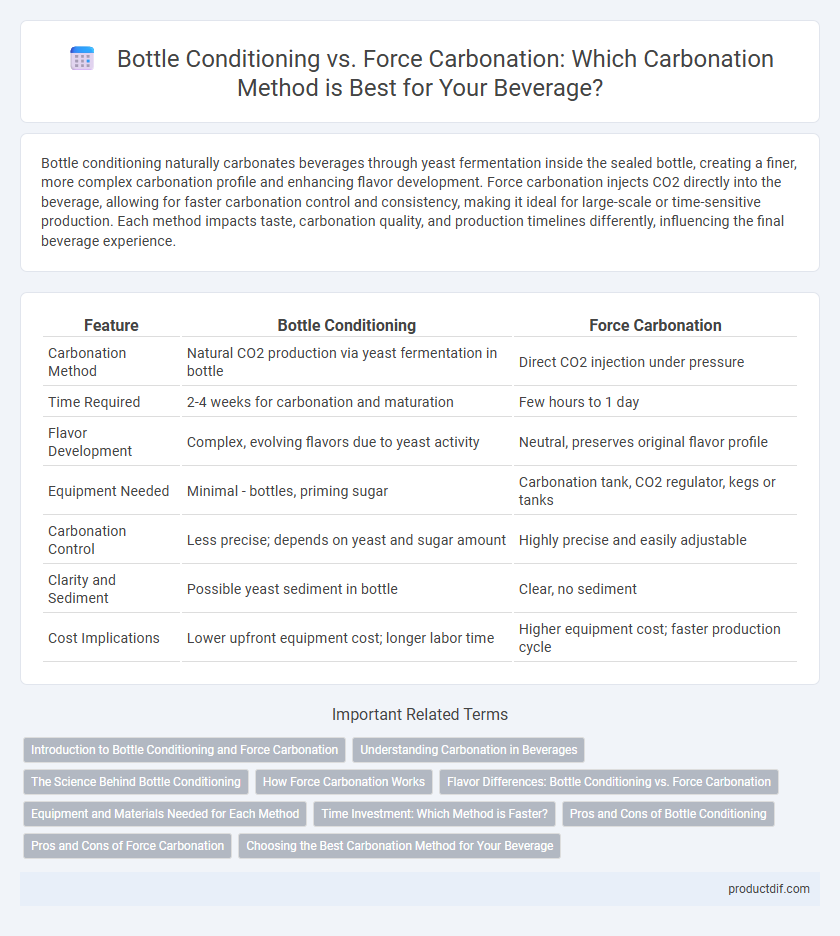

| Feature | Bottle Conditioning | Force Carbonation |

|---|---|---|

| Carbonation Method | Natural CO2 production via yeast fermentation in bottle | Direct CO2 injection under pressure |

| Time Required | 2-4 weeks for carbonation and maturation | Few hours to 1 day |

| Flavor Development | Complex, evolving flavors due to yeast activity | Neutral, preserves original flavor profile |

| Equipment Needed | Minimal - bottles, priming sugar | Carbonation tank, CO2 regulator, kegs or tanks |

| Carbonation Control | Less precise; depends on yeast and sugar amount | Highly precise and easily adjustable |

| Clarity and Sediment | Possible yeast sediment in bottle | Clear, no sediment |

| Cost Implications | Lower upfront equipment cost; longer labor time | Higher equipment cost; faster production cycle |

Introduction to Bottle Conditioning and Force Carbonation

Bottle conditioning is a natural carbonation process where yeast ferments added sugar inside a sealed bottle, producing carbon dioxide and enhancing flavor complexity. Force carbonation involves injecting carbon dioxide directly into the beverage under pressure, allowing for precise control over carbonation levels and faster production. Both methods impact the mouthfeel and taste profile of beverages, with bottle conditioning often favored in craft brewing for its traditional qualities.

Understanding Carbonation in Beverages

Carbonation in beverages is achieved primarily through bottle conditioning or force carbonation, each impacting flavor and texture differently. Bottle conditioning involves natural fermentation inside the bottle, which produces CO2 and creates a complex, effervescent profile favored in craft beers. Force carbonation introduces CO2 directly under pressure, allowing precise control over carbonation levels, commonly used in commercial sodas and beers for consistency.

The Science Behind Bottle Conditioning

Bottle conditioning relies on natural fermentation where yeast consumes priming sugar inside the sealed bottle, producing carbon dioxide that carbonates the beverage. This process creates finer, longer-lasting bubbles and enhances flavor complexity through continued yeast activity. The natural carbonation generated by bottle conditioning contrasts with force carbonation, which injects CO2 directly, resulting in distinct sensory profiles.

How Force Carbonation Works

Force carbonation works by injecting carbon dioxide (CO2) directly into the beverage under controlled pressure, allowing precise regulation of carbonation levels. This process typically occurs in a sealed keg or bottle, where CO2 dissolves rapidly into the liquid, resulting in consistent and immediate carbonation. Force carbonation enables faster production cycles compared to bottle conditioning, making it ideal for commercial beverage production and large-scale distribution.

Flavor Differences: Bottle Conditioning vs. Force Carbonation

Bottle conditioning enhances flavor complexity by allowing yeast to naturally carbonate the beverage, producing subtle esters and a smoother mouthfeel. Force carbonation introduces CO2 directly, resulting in a crisper, more pronounced carbonation but often lacks the depth contributed by yeast activity. Many craft brewers prefer bottle conditioning for richer, layered flavors while larger-scale operations favor force carbonation for consistency and speed.

Equipment and Materials Needed for Each Method

Bottle conditioning requires fermentation-grade bottles, airtight caps or corks, priming sugar, and fermentation yeast, with minimal specialized equipment beyond basic cleaning and bottling tools. Force carbonation demands a CO2 tank, regulator, carbonation stone or inline carbonator, and kegs or pressurizable bottles, along with fittings and pressure-rated tubing to safely infuse carbonation. Both methods benefit from precise temperature control to optimize carbonation levels, but force carbonation typically involves more complex and costly equipment setups.

Time Investment: Which Method is Faster?

Force carbonation significantly reduces the time required to carbonate beverages, often completing the process within 24 to 48 hours by using pressurized CO2 systems. Bottle conditioning, a natural fermentation process, demands a longer time investment, typically ranging from 1 to 3 weeks for optimal carbonation levels to develop. This difference in time efficiency makes force carbonation the preferred method for breweries and homebrewers seeking faster production cycles and quicker product availability.

Pros and Cons of Bottle Conditioning

Bottle conditioning naturally enhances flavor complexity and carbonation through yeast fermentation in the bottle, promoting a traditional artisan quality often preferred in craft beverages. It also provides carbonation stability over time but requires extended aging periods and careful management of yeast sediment, posing challenges for consistency and clarity. Unlike force carbonation, bottle conditioning can lead to variable carbonation levels and occasional off-flavors, demanding more precise control during production.

Pros and Cons of Force Carbonation

Force carbonation allows breweries to precisely control carbonation levels, resulting in consistent and quick carbonation compared to the longer aging process of bottle conditioning. This method reduces the risk of contamination and spoilage since carbonation is achieved in sealed kegs rather than relying on yeast activity in individual bottles. However, force carbonated beverages may lack the complex flavor development associated with natural bottle conditioning, potentially sacrificing some traditional taste nuances.

Choosing the Best Carbonation Method for Your Beverage

Bottle conditioning enhances natural carbonation by allowing yeast to ferment sugars inside the bottle, creating a complex flavor profile ideal for craft beers and traditional ciders. Force carbonation uses CO2 injection for fast, consistent carbonation levels, making it suitable for large-scale production and beverages requiring precise control. Selecting the best method depends on factors like beverage type, desired carbonation level, production scale, and flavor development preferences.

Bottle Conditioning vs Force Carbonation Infographic

productdif.com

productdif.com