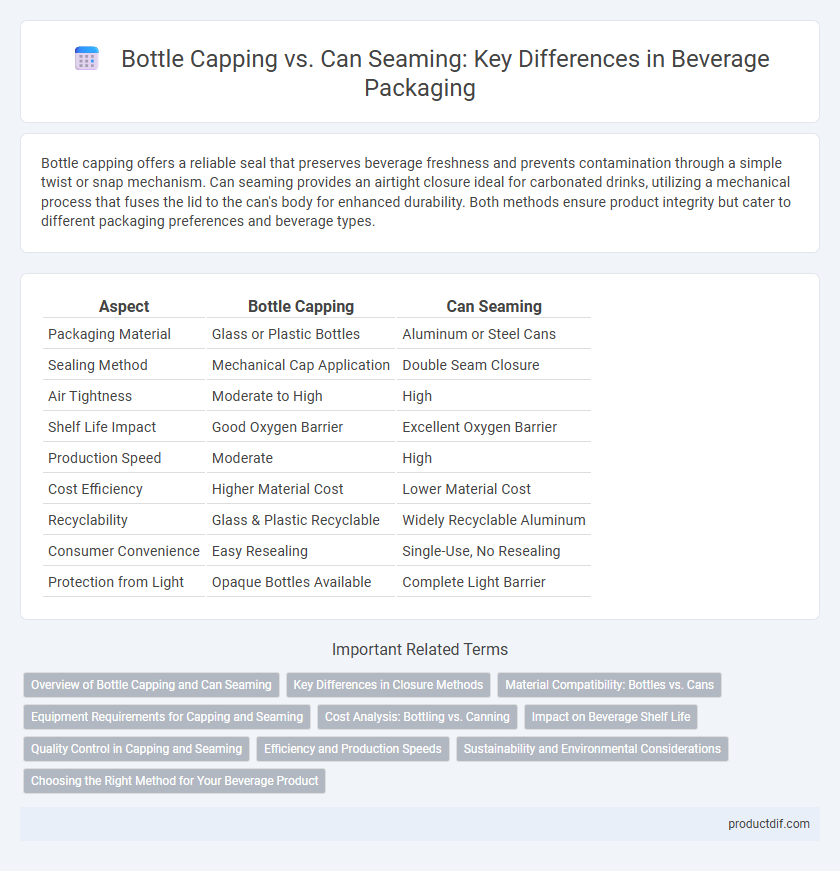

Bottle capping offers a reliable seal that preserves beverage freshness and prevents contamination through a simple twist or snap mechanism. Can seaming provides an airtight closure ideal for carbonated drinks, utilizing a mechanical process that fuses the lid to the can's body for enhanced durability. Both methods ensure product integrity but cater to different packaging preferences and beverage types.

Table of Comparison

| Aspect | Bottle Capping | Can Seaming |

|---|---|---|

| Packaging Material | Glass or Plastic Bottles | Aluminum or Steel Cans |

| Sealing Method | Mechanical Cap Application | Double Seam Closure |

| Air Tightness | Moderate to High | High |

| Shelf Life Impact | Good Oxygen Barrier | Excellent Oxygen Barrier |

| Production Speed | Moderate | High |

| Cost Efficiency | Higher Material Cost | Lower Material Cost |

| Recyclability | Glass & Plastic Recyclable | Widely Recyclable Aluminum |

| Consumer Convenience | Easy Resealing | Single-Use, No Resealing |

| Protection from Light | Opaque Bottles Available | Complete Light Barrier |

Overview of Bottle Capping and Can Seaming

Bottle capping secures beverages in glass or plastic bottles using crown caps, screw caps, or corks, ensuring airtight sealing to preserve freshness and carbonation. Can seaming involves mechanically folding and sealing the aluminum lid onto the can body, creating a hermetic seal that prevents contamination and extends shelf life. Both methods require precise machinery to maintain product quality, but bottle capping suits varied container types while can seaming is standardized for metal cans.

Key Differences in Closure Methods

Bottle capping involves sealing containers with a metal or plastic cap that creates an airtight closure through mechanical pressure, preserving carbonation and freshness. Can seaming uses a double seam process that mechanically joins the can body and lid, ensuring a hermetic seal critical for preventing contamination and maintaining product shelf life. Key differences include the closure material, sealing technique, and suitability for various beverage types, with bottle capping preferred for glass bottles and can seaming optimized for aluminum cans.

Material Compatibility: Bottles vs. Cans

Bottle capping typically involves compatible materials such as glass or plastic bottles paired with metal or plastic caps designed to ensure airtight seals and prevent contamination. Can seaming requires aluminum or steel cans sealed with aluminum lids that provide durability and resistance to environmental factors like moisture and oxygen. Material compatibility plays a crucial role in preserving beverage quality, with bottles offering better resistance to carbonation loss and cans providing superior protection against light and physical damage.

Equipment Requirements for Capping and Seaming

Bottle capping equipment includes automated cappers, torque control systems, and heat induction sealers designed for various cap types like screw, snap, or crown caps. Can seaming requires specialized seaming machines with precision rollers and double seamers that create airtight seals by folding and compressing metal lids onto cans. Both systems demand specific calibration and maintenance to ensure product safety, freshness, and packaging integrity in beverage production.

Cost Analysis: Bottling vs. Canning

Bottle capping generally incurs higher production costs due to the complexity of sealing mechanisms and materials used, whereas can seaming offers cost efficiency with faster sealing times and lower material expenses. Canning reduces logistics costs by being lighter and more compact for shipping and storage, significantly impacting overall cost savings. Evaluating total cost of ownership reveals canning as a more economical option for large-scale beverage production, particularly in high-volume markets.

Impact on Beverage Shelf Life

Bottle capping provides an airtight seal that effectively prevents oxygen and contaminants from entering, thereby extending the beverage's shelf life by maintaining freshness and carbonation. Can seaming creates a hermetic seal that protects against light and air infiltration, crucial for preserving flavor stability and preventing microbial growth. Both methods significantly influence beverage shelf life, with cans offering superior protection against UV light and bottles excelling in resealability after opening.

Quality Control in Capping and Seaming

Bottle capping and can seaming require precise quality control measures to prevent contamination and ensure product freshness. In bottle capping, torque consistency and seal integrity are critical to avoid leakage and maintain carbonation, while can seaming demands accurate double seam formation to secure the lid and protect against microbial ingress. Advanced inspection systems such as automated torque testers for caps and seam scanners for cans play a vital role in detecting defects and optimizing sealing performance.

Efficiency and Production Speeds

Bottle capping typically offers faster production speeds due to simpler machinery and quicker application times, making it ideal for moderate-speed beverage lines. Can seaming, while more complex, provides enhanced sealing integrity for carbonated beverages but may result in slower production rates due to precision requirements in seam formation. Efficiency in bottle capping is driven by lower maintenance and quicker changeovers, whereas can seaming efficiency relies on advanced automation to balance higher quality standards with speed.

Sustainability and Environmental Considerations

Bottle capping typically involves plastic or metal caps that can be recycled but often contribute to microplastic pollution if not properly managed, whereas can seaming uses aluminum, a highly recyclable material with a well-established circular economy. Aluminum cans have a lower carbon footprint in terms of transportation and production efficiency due to their lightweight nature and higher recycling rates compared to bottle caps. Sustainable packaging decisions favor can seaming for minimizing environmental impact, promoting resource conservation, and advancing waste reduction in beverage containers.

Choosing the Right Method for Your Beverage Product

Selecting the ideal closure method for your beverage product hinges on factors like product type, shelf life, and consumer convenience. Bottle capping offers a reliable seal ideal for carbonated drinks and is preferred for easy resealing and premium presentation. Can seaming provides superior airtightness and durability, making it optimal for high-volume production and extended shelf stability in aluminum cans.

Bottle Capping vs Can Seaming Infographic

productdif.com

productdif.com