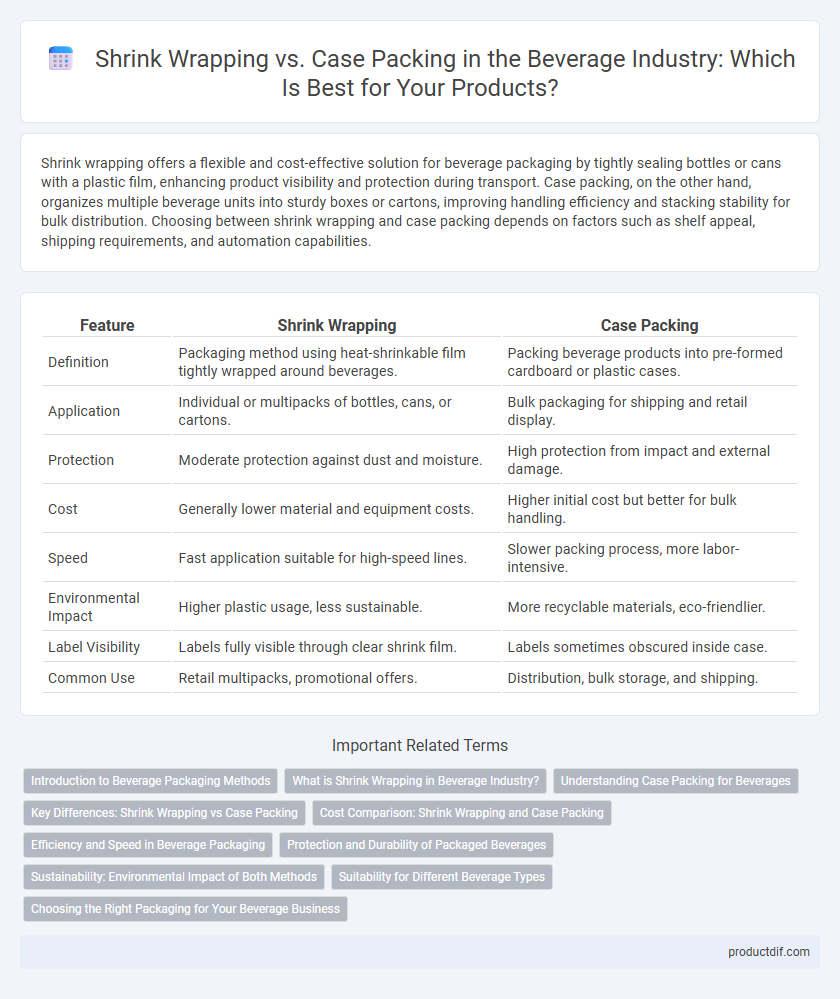

Shrink wrapping offers a flexible and cost-effective solution for beverage packaging by tightly sealing bottles or cans with a plastic film, enhancing product visibility and protection during transport. Case packing, on the other hand, organizes multiple beverage units into sturdy boxes or cartons, improving handling efficiency and stacking stability for bulk distribution. Choosing between shrink wrapping and case packing depends on factors such as shelf appeal, shipping requirements, and automation capabilities.

Table of Comparison

| Feature | Shrink Wrapping | Case Packing |

|---|---|---|

| Definition | Packaging method using heat-shrinkable film tightly wrapped around beverages. | Packing beverage products into pre-formed cardboard or plastic cases. |

| Application | Individual or multipacks of bottles, cans, or cartons. | Bulk packaging for shipping and retail display. |

| Protection | Moderate protection against dust and moisture. | High protection from impact and external damage. |

| Cost | Generally lower material and equipment costs. | Higher initial cost but better for bulk handling. |

| Speed | Fast application suitable for high-speed lines. | Slower packing process, more labor-intensive. |

| Environmental Impact | Higher plastic usage, less sustainable. | More recyclable materials, eco-friendlier. |

| Label Visibility | Labels fully visible through clear shrink film. | Labels sometimes obscured inside case. |

| Common Use | Retail multipacks, promotional offers. | Distribution, bulk storage, and shipping. |

Introduction to Beverage Packaging Methods

Shrink wrapping secures individual beverage containers with a tight plastic film, enhancing product visibility and tamper resistance, while case packing involves grouping multiple units into sturdy, often corrugated boxes for efficient transport and storage. Both methods optimize supply chain logistics by protecting beverage integrity and facilitating automated handling in bottling plants and distribution centers. Choosing between shrink wrapping and case packing depends on factors such as product size, shelf appeal, and retail display requirements.

What is Shrink Wrapping in Beverage Industry?

Shrink wrapping in the beverage industry involves tightly enclosing bottles or cans with a plastic film that shrinks when heated, providing secure protection and improving shelf appeal. This method ensures tamper evidence, moisture resistance, and efficient handling during transportation and storage. Shrink wrapping enhances product visibility while maintaining package integrity, making it a preferred choice for multipacks and promotional bundles.

Understanding Case Packing for Beverages

Case packing for beverages involves securely arranging bottles or cans into standardized boxes, optimizing storage efficiency and transportation safety. Using automated case packing machines ensures consistent product alignment, reduces damage during transit, and improves overall supply chain management. This method is preferred in high-volume beverage production for maintaining product integrity and accelerating packaging speed.

Key Differences: Shrink Wrapping vs Case Packing

Shrink wrapping tightly encloses beverage products in a clear plastic film, providing moisture protection and visibility while reducing package size for efficient transportation. Case packing involves grouping multiple beverage units into a larger corrugated carton, enhancing stackability and offering greater protection during shipping and storage. Key differences include shrink wrapping's flexibility and product visibility versus case packing's sturdiness and ease of handling in bulk distribution.

Cost Comparison: Shrink Wrapping and Case Packing

Shrink wrapping in beverage packaging often incurs lower initial equipment costs compared to case packing, which requires more complex machinery for assembling and sealing cartons. Operational expenses for shrink wrapping are generally reduced due to faster cycle times and less material usage, whereas case packing involves higher labor costs and materials like corrugated boxes. When evaluating cost efficiency, shrink wrapping offers a more economical solution for smaller production runs, while case packing is more cost-effective for large-scale distribution due to enhanced protection and pallet stability.

Efficiency and Speed in Beverage Packaging

Shrink wrapping in beverage packaging offers superior speed by enabling continuous processing and quick bundle formation, reducing downtime compared to case packing, which often requires more manual handling and slower line speeds. Case packing provides higher protection and stability for transportation but typically involves complex machinery and longer setup times, impacting overall efficiency. Optimizing packaging choice depends on balancing throughput demands with product fragility and distribution logistics in beverage operations.

Protection and Durability of Packaged Beverages

Shrink wrapping offers superior protection against moisture, dust, and tampering by tightly sealing beverages in a durable plastic film, enhancing shelf life and reducing product damage during transit. Case packing, using sturdy cardboard or plastic containers, provides robust structural support and stackability, safeguarding beverages from impact and crushing forces. Both methods optimize beverage durability, but shrink wrapping excels in moisture resistance while case packing ensures comprehensive physical protection.

Sustainability: Environmental Impact of Both Methods

Shrink wrapping offers reduced material usage compared to case packing, leading to lower plastic waste generation and improved recyclability. Case packing typically uses cardboard, which is biodegradable and easier to recycle but often involves higher transportation emissions due to bulkier packaging. Evaluating the environmental impact depends on factors like material sourcing, end-of-life disposal, and the carbon footprint of logistics operations.

Suitability for Different Beverage Types

Shrink wrapping offers a flexible packaging solution ideal for irregularly shaped beverage containers such as glass bottles and cans, providing a tight seal that enhances protection during transit. Case packing suits bulkier or uniform beverage products like cartons and large bottles, facilitating efficient stacking and storage in warehouses and retail environments. Both methods optimize product integrity and shelf display depending on specific beverage packaging requirements.

Choosing the Right Packaging for Your Beverage Business

Shrink wrapping offers a cost-effective and flexible solution for securing beverage products, providing excellent protection against moisture and tampering. Case packing, on the other hand, enhances stackability and efficient transportation, ideal for large-scale distribution and retail display. Selecting the right packaging method depends on factors like product fragility, distribution channels, and budget constraints to optimize shelf life and brand presentation.

Shrink Wrapping vs Case Packing Infographic

productdif.com

productdif.com