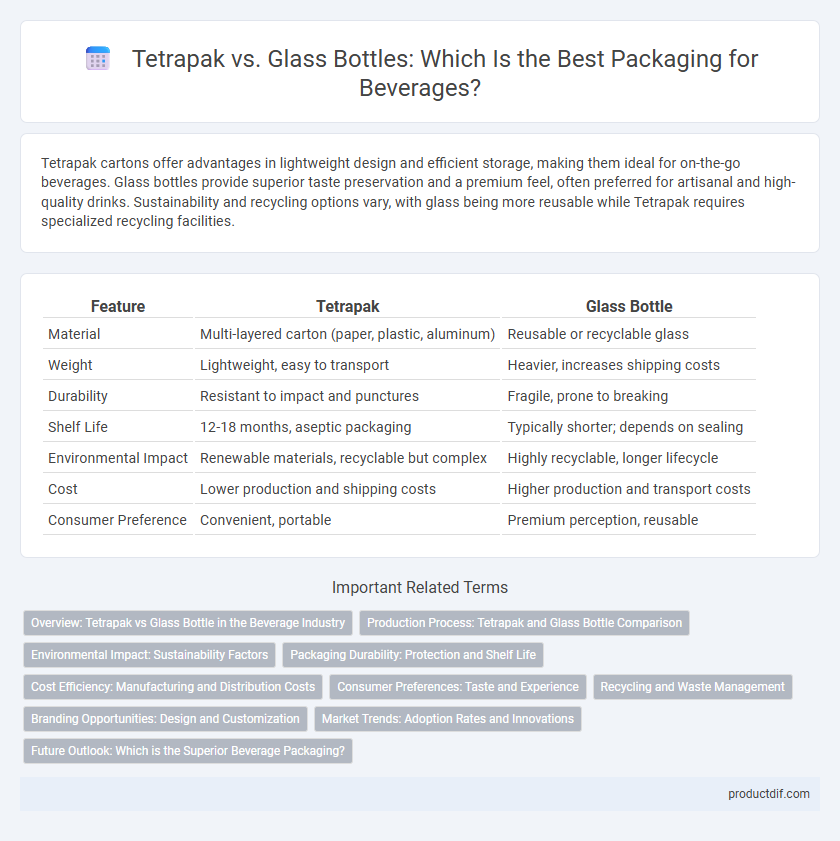

Tetrapak cartons offer advantages in lightweight design and efficient storage, making them ideal for on-the-go beverages. Glass bottles provide superior taste preservation and a premium feel, often preferred for artisanal and high-quality drinks. Sustainability and recycling options vary, with glass being more reusable while Tetrapak requires specialized recycling facilities.

Table of Comparison

| Feature | Tetrapak | Glass Bottle |

|---|---|---|

| Material | Multi-layered carton (paper, plastic, aluminum) | Reusable or recyclable glass |

| Weight | Lightweight, easy to transport | Heavier, increases shipping costs |

| Durability | Resistant to impact and punctures | Fragile, prone to breaking |

| Shelf Life | 12-18 months, aseptic packaging | Typically shorter; depends on sealing |

| Environmental Impact | Renewable materials, recyclable but complex | Highly recyclable, longer lifecycle |

| Cost | Lower production and shipping costs | Higher production and transport costs |

| Consumer Preference | Convenient, portable | Premium perception, reusable |

Overview: Tetrapak vs Glass Bottle in the Beverage Industry

Tetrapak packaging offers lightweight, space-efficient, and cost-effective solutions widely used for juices, milk, and non-carbonated beverages, providing excellent protection against light, air, and contamination. Glass bottles remain preferred for premium beverages and carbonated drinks due to their superior recyclability, inert nature, and ability to preserve flavor integrity without chemical leaching. The beverage industry's choice between Tetrapak and glass bottles hinges on factors like environmental impact, shelf life requirements, and consumer perception of quality and sustainability.

Production Process: Tetrapak and Glass Bottle Comparison

Tetrapak production involves layering paperboard, polyethylene, and aluminum foil through high-speed aseptic filling technology, enabling lightweight, non-breakable, and sterile packaging with minimal energy consumption. Glass bottle manufacturing requires melting raw materials at high temperatures, molding the molten glass into shape, followed by cooling and surface treatment, resulting in a heavier, rigid container with higher carbon emissions. Tetrapak's continuous, automated process contrasts with the batch-based, energy-intensive glass production, influencing sustainability and cost-efficiency in beverage packaging.

Environmental Impact: Sustainability Factors

Tetrapak packaging uses renewable paperboard and consumes less energy during production, resulting in a lower carbon footprint compared to glass bottles, which require higher energy for manufacturing and transportation due to their heavier weight. Glass bottles are 100% recyclable and can be reused multiple times without quality loss, contributing to waste reduction, but their recycling process demands more energy. Sustainable beverage packaging decisions should balance resource consumption, recyclability rates, and carbon emissions to minimize overall environmental impact.

Packaging Durability: Protection and Shelf Life

Tetrapak packaging offers superior protection against light, oxygen, and moisture, significantly extending beverage shelf life compared to glass bottles. Glass bottles provide excellent chemical inertness but are more prone to breakage and require careful handling during transport and storage. The multi-layer design of Tetrapak ensures durability and preserves freshness, making it ideal for long-term storage and distribution.

Cost Efficiency: Manufacturing and Distribution Costs

Tetrapak packaging offers significant cost efficiency in manufacturing due to its lightweight design and automated production processes, reducing material and labor expenses compared to glass bottles. Distribution costs are lower with Tetrapak as its compact shape and lighter weight decrease transportation and storage expenses, unlike the heavier and more fragile glass bottles that require careful handling and increased logistics costs. Overall, Tetrapak provides beverage companies with a more economical solution for large-scale production and global distribution.

Consumer Preferences: Taste and Experience

Consumers often prefer glass bottles for beverages due to the perceived superior taste, as glass is non-reactive and does not alter the flavor profile. Tetrapak packaging offers convenience and lightweight portability but can sometimes impart a slight taste difference because of its multi-layered material composition. The tactile experience of glass, including its weight and clarity, often enhances consumer satisfaction compared to the utilitarian feel of Tetrapak cartons.

Recycling and Waste Management

Tetrapak cartons are lightweight and compact, enabling efficient collection and transportation in recycling programs, but their multi-layered structure of paper, plastic, and aluminum requires specialized facilities for effective separation and recycling. Glass bottles offer high recyclability and can be reused multiple times without quality loss, significantly reducing waste when managed through robust return and refill systems. Waste management efforts benefit from integrating both materials by optimizing infrastructure for Tetrapak's composite recycling and expanding glass bottle reuse programs to minimize environmental impact.

Branding Opportunities: Design and Customization

Tetra Pak cartons offer extensive branding opportunities with vibrant, full-color printing and customizable shapes that enhance shelf appeal and consumer recognition. Glass bottles provide a premium feel and allow for sophisticated label embossing and unique cap designs, reinforcing brand prestige and exclusivity. Both packaging types enable tailored brand messaging, but Tetra Pak's flexibility supports seasonal campaigns and rapid design changes more efficiently.

Market Trends: Adoption Rates and Innovations

Tetrapak packaging has experienced rapid adoption in the beverage market due to its lightweight, sustainability, and convenience, capturing a significant share in dairy and juice sectors. Glass bottles maintain a steady niche for premium beverages, leveraging consumer preference for recyclability, reusability, and perceived quality. Innovations in Tetrapak involve enhanced barrier properties and eco-friendly materials, while glass packaging evolves with lightweight designs and smart labeling technologies to boost market penetration.

Future Outlook: Which is the Superior Beverage Packaging?

Tetrapak packaging offers superior sustainability through lightweight design and high recyclability, contributing to reduced carbon footprints in beverage distribution. Glass bottles provide premium consumer perception and infinite recyclability but face challenges in transportation energy and breakage risk. The future outlook favors Tetrapak for mass-market efficiency while glass bottles remain preferred in luxury and niche segments, driven by evolving consumer priorities and environmental regulations.

Tetrapak vs Glass Bottle Infographic

productdif.com

productdif.com