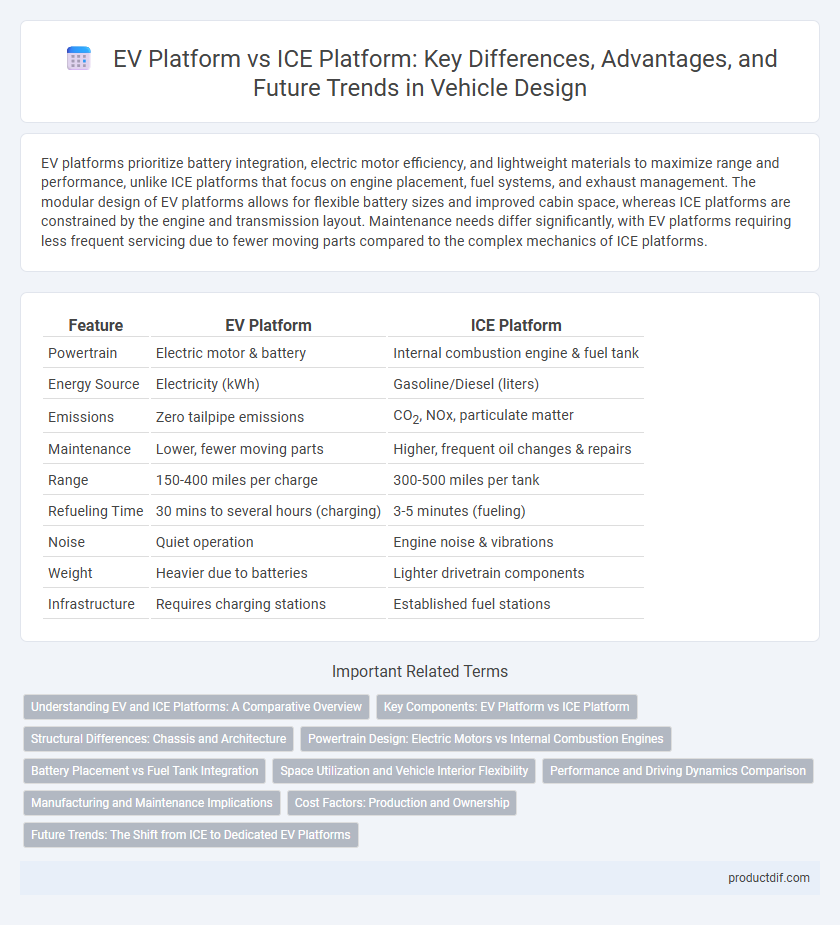

EV platforms prioritize battery integration, electric motor efficiency, and lightweight materials to maximize range and performance, unlike ICE platforms that focus on engine placement, fuel systems, and exhaust management. The modular design of EV platforms allows for flexible battery sizes and improved cabin space, whereas ICE platforms are constrained by the engine and transmission layout. Maintenance needs differ significantly, with EV platforms requiring less frequent servicing due to fewer moving parts compared to the complex mechanics of ICE platforms.

Table of Comparison

| Feature | EV Platform | ICE Platform |

|---|---|---|

| Powertrain | Electric motor & battery | Internal combustion engine & fuel tank |

| Energy Source | Electricity (kWh) | Gasoline/Diesel (liters) |

| Emissions | Zero tailpipe emissions | CO2, NOx, particulate matter |

| Maintenance | Lower, fewer moving parts | Higher, frequent oil changes & repairs |

| Range | 150-400 miles per charge | 300-500 miles per tank |

| Refueling Time | 30 mins to several hours (charging) | 3-5 minutes (fueling) |

| Noise | Quiet operation | Engine noise & vibrations |

| Weight | Heavier due to batteries | Lighter drivetrain components |

| Infrastructure | Requires charging stations | Established fuel stations |

Understanding EV and ICE Platforms: A Comparative Overview

EV platforms prioritize integrated battery packs and electric drive units, enabling greater floor space and weight distribution optimization compared to ICE platforms, which house internal combustion engines and transmissions. The modular design of EV platforms supports faster development of various vehicle types with enhanced efficiency and lower emissions. In contrast, ICE platforms rely on complex mechanical components and fuel systems that increase vehicle weight and maintenance requirements.

Key Components: EV Platform vs ICE Platform

EV platforms integrate high-capacity lithium-ion battery packs, electric motors, and power electronics as key components, enabling efficient energy storage and propulsion. ICE platforms rely on internal combustion engines, fuel tanks, transmissions, and exhaust systems to generate and manage power through fuel combustion. The structural design of EV platforms prioritizes battery placement and thermal management, while ICE platforms focus on engine mounting and fuel delivery systems.

Structural Differences: Chassis and Architecture

EV platforms feature a flat battery pack integrated into the floor, enabling a lower center of gravity and enhanced structural rigidity compared to ICE platforms, which require space for a large engine and transmission tunnel. The absence of a bulky internal combustion engine allows EV chassis to have simplified, modular architectures designed for optimized weight distribution and improved energy efficiency. ICE platforms typically involve complex frame structures to accommodate heavy engine mounts, exhaust systems, and fuel tanks, resulting in higher vehicle weight and a less flexible interior layout.

Powertrain Design: Electric Motors vs Internal Combustion Engines

Electric vehicle (EV) platforms integrate compact electric motors that deliver instant torque, enabling smoother acceleration and enhanced energy efficiency compared to traditional internal combustion engine (ICE) powertrains. The design of EV powertrains allows for fewer moving parts, reducing mechanical complexity, maintenance needs, and improving overall reliability. In contrast, ICE platforms rely on multi-component engines with combustion chambers, fuel injectors, and exhaust systems, resulting in greater weight and spatial constraints that affect vehicle packaging and performance.

Battery Placement vs Fuel Tank Integration

EV platforms prioritize battery placement typically beneath the vehicle floor, optimizing weight distribution and increasing cabin space, while ICE platforms integrate fuel tanks within the chassis or rear compartment, often limiting design flexibility. Battery placement in EVs enhances structural rigidity and safety by creating a low center of gravity, contrasting with fuel tank placement in ICE vehicles, which requires additional protective measures due to flammability risks. This fundamental difference in energy storage integration drives distinct architectural and performance advantages between electric and internal combustion engine vehicles.

Space Utilization and Vehicle Interior Flexibility

Electric vehicle (EV) platforms offer superior space utilization compared to internal combustion engine (ICE) platforms due to the compact design of electric drivetrains and the absence of bulky engine components, freeing up more interior cabin and cargo space. The flat battery pack integrated into the floor enhances vehicle interior flexibility, allowing for innovative seating arrangements and increased legroom. In contrast, ICE platforms require engine bays and transmission tunnels, limiting layout options and reducing overall passenger comfort and storage capacity.

Performance and Driving Dynamics Comparison

EV platforms provide instant torque delivery, resulting in faster acceleration and more responsive driving dynamics compared to ICE platforms. The lower center of gravity in EVs, due to battery placement, enhances stability and cornering performance, offering superior handling characteristics. In contrast, ICE platforms often experience weight distribution challenges and delayed torque response, limiting overall performance efficiency.

Manufacturing and Maintenance Implications

EV platforms simplify manufacturing through modular design and fewer moving parts compared to ICE platforms, enabling faster assembly and lower production costs. Maintenance requirements for EVs are reduced due to fewer components like no oil changes, fuel systems, or exhaust maintenance, which translates to lower long-term service expenses. Manufacturing investments shift towards battery technology and electric drivetrains, while ICE platforms demand extensive infrastructure for internal combustion engines and emissions control systems.

Cost Factors: Production and Ownership

EV platforms generally incur higher initial production costs due to expensive battery packs and specialized electric drivetrains, but offer lower long-term ownership expenses through reduced maintenance and fuel costs. ICE platforms involve lower manufacturing expenses with established supply chains but face increasing operational costs from fuel, regular servicing, and emissions compliance. Total cost of ownership for EVs tends to decrease over time, especially with advances in battery technology and government incentives.

Future Trends: The Shift from ICE to Dedicated EV Platforms

Future trends in vehicle manufacturing highlight a significant shift from internal combustion engine (ICE) platforms to dedicated electric vehicle (EV) platforms, driven by advancements in battery technology and regulatory pressures for sustainability. Dedicated EV platforms enable optimized battery placement, improved energy efficiency, and enhanced interior space compared to the retrofitted ICE platforms. This transition supports innovations like modular designs, faster charging systems, and autonomous driving capabilities, setting the foundation for next-generation electric mobility.

EV platform vs ICE platform Infographic

productdif.com

productdif.com