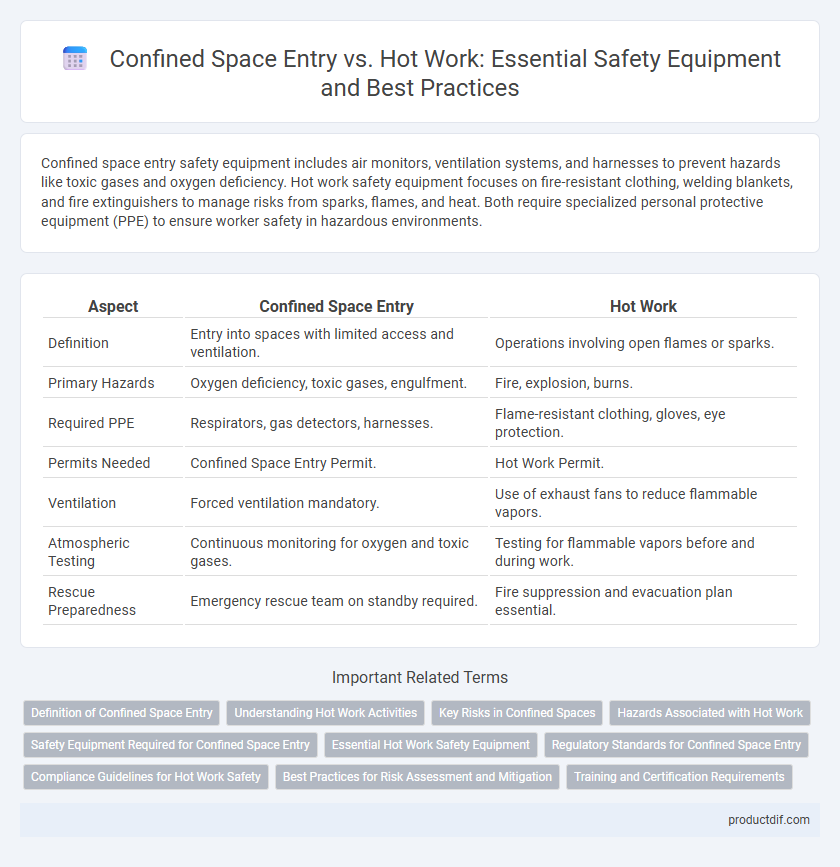

Confined space entry safety equipment includes air monitors, ventilation systems, and harnesses to prevent hazards like toxic gases and oxygen deficiency. Hot work safety equipment focuses on fire-resistant clothing, welding blankets, and fire extinguishers to manage risks from sparks, flames, and heat. Both require specialized personal protective equipment (PPE) to ensure worker safety in hazardous environments.

Table of Comparison

| Aspect | Confined Space Entry | Hot Work |

|---|---|---|

| Definition | Entry into spaces with limited access and ventilation. | Operations involving open flames or sparks. |

| Primary Hazards | Oxygen deficiency, toxic gases, engulfment. | Fire, explosion, burns. |

| Required PPE | Respirators, gas detectors, harnesses. | Flame-resistant clothing, gloves, eye protection. |

| Permits Needed | Confined Space Entry Permit. | Hot Work Permit. |

| Ventilation | Forced ventilation mandatory. | Use of exhaust fans to reduce flammable vapors. |

| Atmospheric Testing | Continuous monitoring for oxygen and toxic gases. | Testing for flammable vapors before and during work. |

| Rescue Preparedness | Emergency rescue team on standby required. | Fire suppression and evacuation plan essential. |

Definition of Confined Space Entry

Confined space entry involves accessing areas not designed for continuous occupancy, with limited means of entry or exit, such as tanks, vessels, or sewers, posing risks like oxygen deficiency and toxic atmospheres. Proper safety equipment includes gas detectors, ventilation systems, and personal protective gear to mitigate hazardous environments. This contrasts with hot work, which focuses on activities generating ignition sources within or near flammable materials, requiring fire-resistant clothing and fire watch protocols.

Understanding Hot Work Activities

Hot work activities involve operations such as welding, cutting, grinding, and brazing that generate sparks, flames, or heat capable of igniting flammable materials. Proper safety equipment, including fire-resistant clothing, fire extinguishers, and gas detectors, is essential to prevent fires and explosions during these tasks. Understanding the specific risks of hot work in confined spaces requires strict adherence to permits, ventilation controls, and continuous atmospheric monitoring to ensure worker safety.

Key Risks in Confined Spaces

Confined space entry poses key risks including limited oxygen levels, toxic gas accumulation, and restricted egress, increasing the potential for asphyxiation and poisoning. Unlike hot work, which primarily involves fire and explosion hazards from ignition sources, confined spaces demand continuous atmospheric monitoring and emergency preparedness to mitigate entrapment and hazardous exposure. Proper training, ventilation, and use of personal protective equipment (PPE) are critical to ensuring worker safety during confined space operations.

Hazards Associated with Hot Work

Hot work presents significant hazards including fire, explosions, and exposure to toxic fumes due to welding, cutting, or grinding in confined spaces. The risk of igniting flammable gases or materials requires strict safety controls such as continuous atmospheric monitoring and the use of fire-resistant barriers. Proper ventilation, personal protective equipment, and adherence to hot work permits are essential to mitigate these dangers in confined space entry operations.

Safety Equipment Required for Confined Space Entry

Safety equipment required for confined space entry includes full-body harnesses, gas detectors, and supplied-air respirators to ensure worker safety in oxygen-deficient or toxic atmospheres. Intrinsically safe lighting and communication devices are essential to prevent ignition of flammable gases during entry. Continuous atmospheric monitoring and emergency rescue equipment must be readily available to respond promptly to hazardous conditions within confined spaces.

Essential Hot Work Safety Equipment

Essential hot work safety equipment includes fire-resistant clothing, flame-retardant gloves, and safety goggles to protect against sparks and heat exposure. Portable fire extinguishers, fire blankets, and welding screens are critical to prevent and control potential fires during hot work operations. Proper ventilation systems and gas detectors are necessary to monitor hazardous fumes and maintain a safe atmosphere in confined spaces where hot work is conducted.

Regulatory Standards for Confined Space Entry

Regulatory standards for confined space entry prioritize strict hazard identification, atmospheric testing, and continuous monitoring to prevent suffocation, toxic exposure, or engulfment. OSHA's 29 CFR 1910.146 outlines detailed permit-required confined space entry procedures, emphasizing training, rescue plans, and communication protocols. In contrast, hot work regulations focus on fire prevention through permits and fire watch, making confined space entry standards uniquely comprehensive in addressing diverse physical and atmospheric risks.

Compliance Guidelines for Hot Work Safety

Compliance guidelines for hot work safety emphasize strict permit-to-work systems, continuous atmospheric monitoring for flammable gases, and mandatory fire watch during and after operations near confined spaces. Proper ventilation and use of personal protective equipment (PPE), including flame-resistant clothing and respiratory protection, are essential to prevent accidents. Adhering to standards such as OSHA 29 CFR 1910.252 and NFPA 51B ensures comprehensive risk management and regulatory compliance in hazardous environments.

Best Practices for Risk Assessment and Mitigation

Confined space entry and hot work require thorough risk assessments to identify hazards such as limited oxygen, toxic gases, flammable vapors, and ignition sources. Implementing continuous atmospheric monitoring, proper ventilation, and strict permit-to-work systems significantly reduces the likelihood of accidents. Employing specialized personal protective equipment (PPE) and ensuring trained personnel follow standardized emergency procedures are crucial for effective risk mitigation.

Training and Certification Requirements

Confined space entry demands specialized training on hazard identification, atmospheric monitoring, and emergency rescue procedures, often requiring certification such as OSHA's Confined Space Entry Program. Hot work training focuses on fire prevention, proper use of protective gear, and fire watch protocols, with certifications like NFPA 51B ensuring compliance. Both require documented competency assessments to minimize risks and certify worker readiness for hazardous environments.

Confined space entry vs Hot work Infographic

productdif.com

productdif.com