Push-fit connections in plumbing fixtures allow for quick and tool-free installation, making them ideal for DIY projects and repairs where ease and speed are priorities. Solvent weld connections, on the other hand, create a permanent bond by chemically fusing pipes and fittings, ensuring a durable and leak-proof seal suitable for high-pressure systems. Choosing between push-fit and solvent weld connections depends on the specific plumbing requirements, with push-fit offering convenience and solvent weld offering long-term reliability.

Table of Comparison

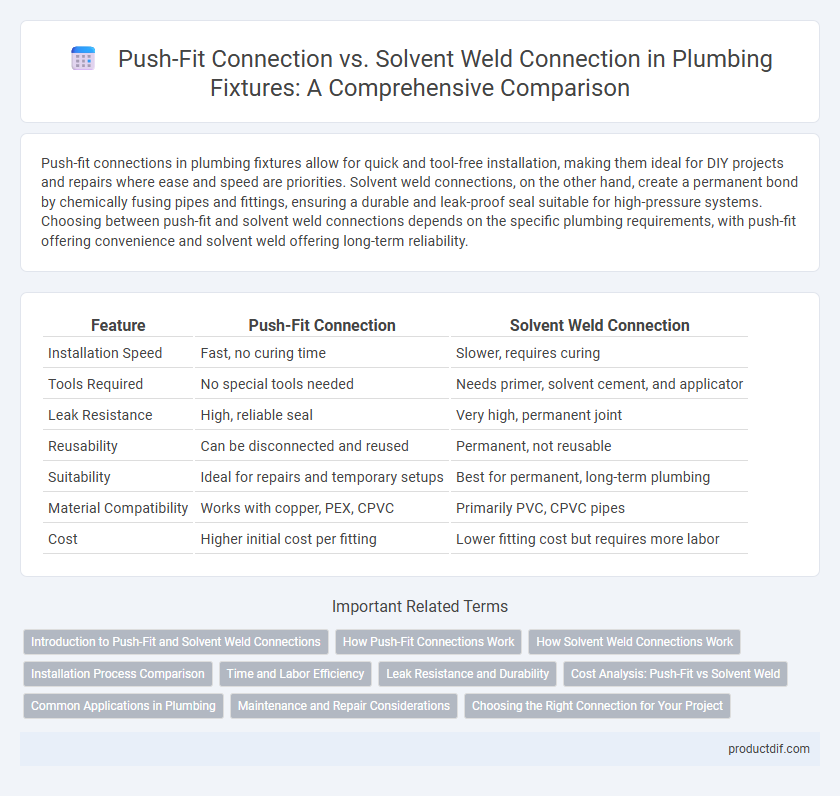

| Feature | Push-Fit Connection | Solvent Weld Connection |

|---|---|---|

| Installation Speed | Fast, no curing time | Slower, requires curing |

| Tools Required | No special tools needed | Needs primer, solvent cement, and applicator |

| Leak Resistance | High, reliable seal | Very high, permanent joint |

| Reusability | Can be disconnected and reused | Permanent, not reusable |

| Suitability | Ideal for repairs and temporary setups | Best for permanent, long-term plumbing |

| Material Compatibility | Works with copper, PEX, CPVC | Primarily PVC, CPVC pipes |

| Cost | Higher initial cost per fitting | Lower fitting cost but requires more labor |

Introduction to Push-Fit and Solvent Weld Connections

Push-fit connections offer a fast, tool-free method for joining plumbing fixtures using gasket-sealed fittings that create a watertight seal when pipes are pushed together, ideal for repairs and renovations. Solvent weld connections rely on chemical adhesives to fuse PVC or CPVC pipes permanently, providing a strong, leak-proof joint commonly used in new installations and high-pressure applications. Both methods ensure secure plumbing systems, but push-fit connections prioritize ease and speed, while solvent weld connections emphasize durability and permanence.

How Push-Fit Connections Work

Push-fit connections use a simple push mechanism to join pipes without the need for heat, glue, or specialized tools. They feature internal O-rings and metal teeth that grip and seal the pipe securely, ensuring a watertight and reliable connection. This system allows quick and easy installation or removal, making it ideal for plumbing repairs and modifications.

How Solvent Weld Connections Work

Solvent weld connections create a strong, permanent bond by chemically fusing plastic pipes and fittings through a solvent that softens the surfaces, allowing them to meld together as the solvent evaporates. This method ensures a leak-proof seal ideal for high-pressure plumbing systems and requires proper curing time for optimal strength. Unlike push-fit connections, solvent welds do not allow for easy disassembly, providing a durable and reliable joint for long-term plumbing installations.

Installation Process Comparison

Push-fit connections offer a quick, tool-free installation process by simply pushing pipes into the fitting, making them ideal for DIY projects and reducing labor time. Solvent weld connections require applying a chemical solvent to soften and fuse the pipe and fitting, creating a permanent, leak-proof bond but necessitating curing time and careful surface preparation. While push-fit allows immediate use, solvent weld ensures higher durability in long-term plumbing systems.

Time and Labor Efficiency

Push-fit connections offer significant time and labor savings by enabling quick, tool-free assembly, reducing installation time by up to 50% compared to solvent weld connections. Solvent weld connections require precise surface preparation, application of primer and solvent cement, and curing time, resulting in longer installation processes and higher labor intensity. For large-scale plumbing projects, push-fit fittings improve overall efficiency by minimizing downtime and labor costs associated with traditional solvent welding methods.

Leak Resistance and Durability

Push-fit connections offer superior leak resistance due to their flexible sealing rings, which create a watertight seal without the need for adhesives. Solvent weld connections provide exceptional durability by chemically bonding pipes and fittings, creating a permanent, strong joint ideal for high-pressure applications. While push-fit is easier to install and remove, solvent weld connections excel in long-term reliability and resistance to mechanical stress.

Cost Analysis: Push-Fit vs Solvent Weld

Push-fit connections for plumbing fixtures offer higher upfront costs due to premium materials but reduce labor expenses with faster installation times. Solvent weld connections have lower material costs but require skilled labor and longer curing times, increasing overall installation costs. Evaluating total project expenses reveals push-fit systems often provide cost savings on labor despite higher initial prices, making them economically advantageous for time-sensitive or complex plumbing tasks.

Common Applications in Plumbing

Push-fit connections are commonly used in residential plumbing for quick repairs and installations of water supply lines, especially in tight spaces where ease of assembly is crucial. Solvent weld connections are prevalent in drain, waste, and vent (DWV) systems and in applications requiring a permanent, leak-proof bond, such as PVC pipe installations for waste removal. Both methods serve distinct roles, with push-fit offering flexibility and speed, while solvent weld ensures durability and chemical resistance in plumbing fixtures.

Maintenance and Repair Considerations

Push-fit connections in plumbing fixtures simplify maintenance and repair by allowing quick disassembly without specialized tools, reducing downtime and labor costs. Solvent weld connections, while offering a strong, permanent bond, require cutting and re-gluing pipes during repairs, increasing time and complexity for maintenance tasks. Selecting push-fit fittings enhances flexibility for frequent servicing, whereas solvent welds are suited for long-term installations with minimal intervention.

Choosing the Right Connection for Your Project

Push-fit connections offer quick, tool-free installation, ideal for temporary setups or projects needing frequent adjustments, while solvent weld connections create permanent, leak-proof seals best suited for long-term plumbing systems. Assessing factors such as project duration, pipe material compatibility, and potential exposure to pressure or temperature variations helps determine the optimal connection type. For durable, reliable plumbing installations in residential or commercial applications, solvent welds typically provide stronger joints, whereas push-fit solutions excel in flexibility and ease of use.

push-fit connection vs solvent weld connection Infographic

productdif.com

productdif.com