Push-fit fittings offer a quick, tool-free installation ideal for DIY plumbing repairs, providing flexibility and ease of use without the need for heat or solder. Soldered fittings create a permanent, watertight seal through high-temperature bonding, ensuring durability and reliability for long-term plumbing systems. Choosing between push-fit and soldered fittings depends on the project's requirements for speed, permanence, and pipe material compatibility.

Table of Comparison

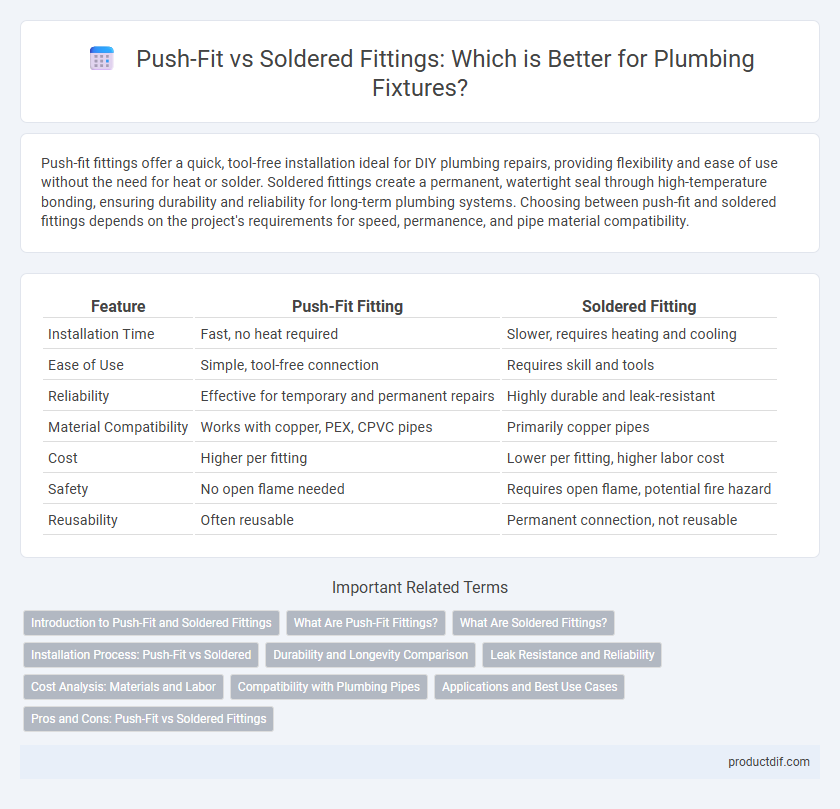

| Feature | Push-Fit Fitting | Soldered Fitting |

|---|---|---|

| Installation Time | Fast, no heat required | Slower, requires heating and cooling |

| Ease of Use | Simple, tool-free connection | Requires skill and tools |

| Reliability | Effective for temporary and permanent repairs | Highly durable and leak-resistant |

| Material Compatibility | Works with copper, PEX, CPVC pipes | Primarily copper pipes |

| Cost | Higher per fitting | Lower per fitting, higher labor cost |

| Safety | No open flame needed | Requires open flame, potential fire hazard |

| Reusability | Often reusable | Permanent connection, not reusable |

Introduction to Push-Fit and Soldered Fittings

Push-fit fittings offer a fast, tool-free connection method ideal for copper, CPVC, and PEX pipes, using an internal O-ring and stainless steel teeth to secure pipes without soldering. Soldered fittings require heating the joint with a torch and applying molten solder to create a strong, leak-resistant bond, commonly used in traditional copper plumbing systems. Push-fit fittings provide ease and speed suited for quick repairs, while soldered fittings offer durability and reliability for permanent installations.

What Are Push-Fit Fittings?

Push-fit fittings are plumbing connectors designed for quick and easy installation without the need for soldering, clamps, or glue. These fittings use an internal O-ring and metal teeth to create a watertight seal on copper, PEX, or CPVC pipes, making them ideal for repairs and modifications. Engineered to save time and reduce labor costs, push-fit fittings are widely used in residential and commercial plumbing systems for their reliability and versatility.

What Are Soldered Fittings?

Soldered fittings are plumbing connectors joined by melting a filler metal, typically lead-free solder, to create a strong, leak-resistant bond between copper pipes. This method requires heating the fitting and pipe with a torch until the solder melts and flows into the joint, ensuring a durable and permanent connection. Soldered fittings are widely used in residential and commercial copper piping systems due to their reliability and resistance to high pressure and temperature.

Installation Process: Push-Fit vs Soldered

Push-fit fittings offer a tool-free, quick installation process by simply pushing the pipe into the fitting, creating a watertight seal without heat or solder, ideal for DIY projects and emergency repairs. Soldered fittings require cleaning, flux application, and precise heating with a torch to melt solder around the joint, ensuring a durable, leak-resistant connection best suited for professional plumbing and permanent installations. Push-fit installation minimizes downtime and fire hazards, while soldering demands skill and time but delivers higher strength and longevity in high-pressure or high-temperature systems.

Durability and Longevity Comparison

Push-fit fittings offer convenient installation with moderate durability, but they generally have a shorter lifespan compared to soldered fittings. Soldered fittings create a strong, permanent bond through copper-to-copper connections, enhancing resistance to leaks and corrosion over decades. For long-term plumbing projects, soldered fittings are preferred due to their superior durability and proven longevity under high-pressure and temperature conditions.

Leak Resistance and Reliability

Push-fit fittings offer superior leak resistance due to their rubber O-ring seals that create a watertight connection without the need for heat, reducing the risk of joint failure. Soldered fittings, while traditionally reliable, depend heavily on the quality of the soldering technique and proper heating, which can introduce weaknesses or leaks if done improperly. In terms of long-term reliability, push-fit fittings provide consistent performance with minimal maintenance, whereas soldered joints may require periodic inspection for potential leaks caused by corrosion or thermal expansion.

Cost Analysis: Materials and Labor

Push-fit fittings typically reduce labor costs due to their ease of installation, requiring no special tools or skills, while soldered fittings involve higher labor expenses from preparation, heating, and cooling time. Material costs for push-fit fittings are generally higher since they use advanced polymers or metals with sealing mechanisms, whereas soldered fittings rely on more affordable copper and solder. Overall, push-fit fittings offer cost savings in labor-intensive projects, but soldered fittings may be more economical for materials in large-scale plumbing installations.

Compatibility with Plumbing Pipes

Push-fit fittings offer superior compatibility with a wide range of plumbing pipes, including copper, PEX, and CPVC, due to their versatile design and flexible sealing mechanisms. Soldered fittings, however, are primarily compatible only with copper pipes, requiring clean, fluxed surfaces and heat application for a secure, leak-proof connection. This makes push-fit fittings preferable for retrofit or mixed-pipe systems, while soldered fittings excel in permanent copper pipe installations where long-term durability is critical.

Applications and Best Use Cases

Push-fit fittings excel in applications requiring quick, tool-free installation and frequent maintenance, making them ideal for DIY projects, residential repairs, and temporary piping setups. Soldered fittings provide a durable, leak-resistant connection suited for high-pressure systems, commercial plumbing, and permanent installations where long-term reliability is critical. Choosing between push-fit and soldered fittings depends on the need for speed and flexibility versus the demand for strength and durability in plumbing fixtures.

Pros and Cons: Push-Fit vs Soldered Fittings

Push-fit fittings offer quick, tool-free installation ideal for DIY or emergency repairs, providing flexibility and reusability, but they may have limitations in high-pressure or high-temperature environments. Soldered fittings ensure a strong, permanent, and leak-resistant joint suited for long-term plumbing systems, though they require specialized skills, equipment, and more time to install. Choosing between push-fit and soldered fittings depends on factors like installation speed, durability, and the specific plumbing application requirements.

push-fit fitting vs soldered fitting Infographic

productdif.com

productdif.com