PEX piping offers flexibility, corrosion resistance, and easier installation compared to rigid copper piping, making it a popular choice for modern plumbing fixtures for pets. Copper piping provides durability and natural antimicrobial properties but can be more expensive and prone to freezing in colder climates. Selecting between PEX and copper depends on factors like budget, environmental conditions, and specific pet plumbing requirements.

Table of Comparison

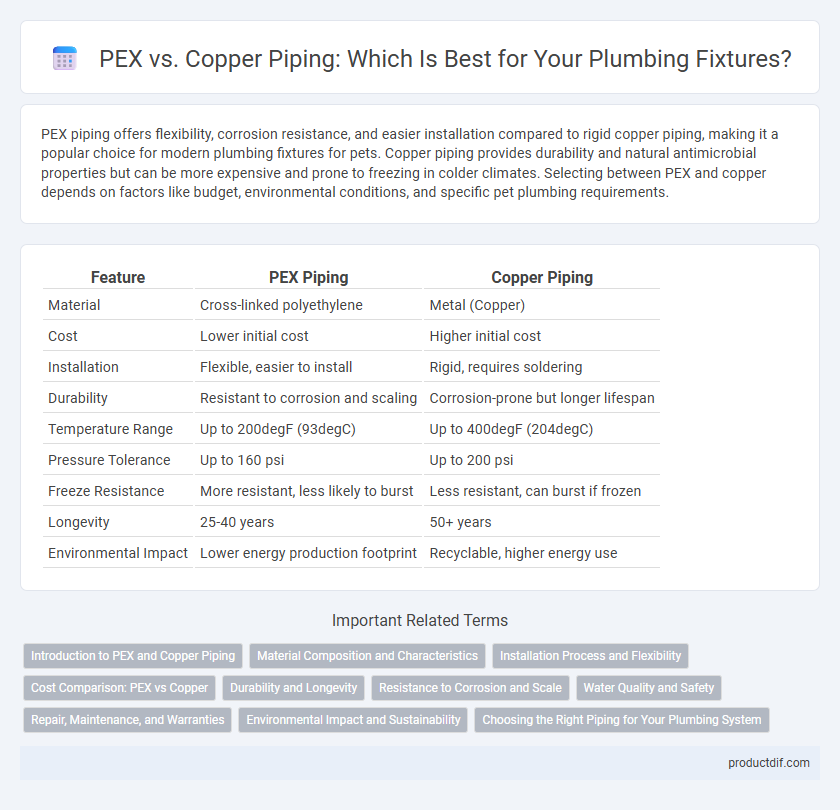

| Feature | PEX Piping | Copper Piping |

|---|---|---|

| Material | Cross-linked polyethylene | Metal (Copper) |

| Cost | Lower initial cost | Higher initial cost |

| Installation | Flexible, easier to install | Rigid, requires soldering |

| Durability | Resistant to corrosion and scaling | Corrosion-prone but longer lifespan |

| Temperature Range | Up to 200degF (93degC) | Up to 400degF (204degC) |

| Pressure Tolerance | Up to 160 psi | Up to 200 psi |

| Freeze Resistance | More resistant, less likely to burst | Less resistant, can burst if frozen |

| Longevity | 25-40 years | 50+ years |

| Environmental Impact | Lower energy production footprint | Recyclable, higher energy use |

Introduction to PEX and Copper Piping

PEX piping offers flexibility, resistance to scale and chlorine, and easier installation compared to traditional copper pipes, making it a popular choice in modern plumbing systems. Copper piping, known for its durability, corrosion resistance, and long lifespan, remains a trusted material, especially for water supply lines and heating systems. Both materials have distinct advantages, with PEX excelling in efficiency and cost-effectiveness while copper provides proven reliability and antimicrobial properties.

Material Composition and Characteristics

PEX piping is made of flexible cross-linked polyethylene, offering high resistance to corrosion, scale buildup, and freeze damage, making it durable and adaptable for various plumbing applications. Copper piping consists of natural metal known for its strength, heat tolerance, and antimicrobial properties, providing long-lasting performance but higher susceptibility to corrosion in acidic water conditions. The choice between PEX and copper depends on factors like installation complexity, environmental conditions, and budget considerations related to material durability and thermal conductivity.

Installation Process and Flexibility

PEX piping offers a faster and more straightforward installation process compared to copper, as it is flexible and requires fewer fittings and soldering steps. Copper piping demands precise cutting, soldering skills, and specialized tools, which increases labor time and complexity. The flexibility of PEX allows it to bend around corners and obstacles easily, reducing the need for joints and minimizing leak potential during plumbing fixture installation.

Cost Comparison: PEX vs Copper

PEX piping generally costs 20-30% less than copper due to lower material and installation expenses. Copper prices are subject to market volatility, often making PEX a more budget-friendly choice for large plumbing projects. Labor costs for copper are higher because of soldering requirements, while PEX's flexible design reduces installation time and overall expenses.

Durability and Longevity

PEX piping offers excellent durability with resistance to corrosion, scale buildup, and freeze damage, often lasting 40-50 years in plumbing systems. Copper piping is renowned for its long-term reliability, typically enduring 50-70 years due to its natural antimicrobial properties and robustness against UV rays and physical damage. Selecting between PEX and copper depends on environmental conditions and expected lifespan requirements in plumbing installations.

Resistance to Corrosion and Scale

PEX piping exhibits superior resistance to corrosion and scale buildup compared to copper piping, which is prone to oxidation and mineral deposits over time. The flexible, plastic composition of PEX prevents rust formation and maintains consistent water flow, making it ideal for areas with hard water. Copper pipes, while durable, often require additional maintenance to address corrosion-related issues that can compromise plumbing system efficiency.

Water Quality and Safety

PEX piping offers excellent resistance to scale and chlorine, maintaining water quality by minimizing corrosion and metal leaching common in copper pipes. Copper piping is naturally antimicrobial, reducing bacterial growth and enhancing safety in potable water systems. Both materials comply with NSF/ANSI standards, but PEX's flexibility reduces joint leaks, while copper's durability withstands high temperatures and pressure, ensuring long-term water safety.

Repair, Maintenance, and Warranties

PEX piping offers easier repair and maintenance with flexible tubing that resists corrosion and scaling, reducing the likelihood of leaks and breaks compared to copper. Copper piping requires soldering or specialized fittings for repairs, which can be more labor-intensive and costly over time. PEX warranties often cover up to 25 years due to its durability, while copper warranties generally range from 10 to 20 years, reflecting differences in material longevity and installation complexity.

Environmental Impact and Sustainability

PEX piping offers significant environmental benefits over copper due to its lower energy consumption during production and reduced greenhouse gas emissions. Copper extraction and manufacturing require intensive mining and smelting processes that contribute to habitat destruction and pollution. PEX's flexibility and durability also minimize leaks and water waste, enhancing overall sustainability in plumbing systems.

Choosing the Right Piping for Your Plumbing System

PEX piping offers superior flexibility, corrosion resistance, and easier installation compared to copper, making it ideal for complex plumbing layouts and renovation projects. Copper piping provides unmatched durability, fire resistance, and longevity, which benefits homes requiring high-pressure and temperature tolerance. Selecting the right piping depends on factors like budget, local building codes, water quality, and long-term performance needs.

PEX vs Copper Piping Infographic

productdif.com

productdif.com