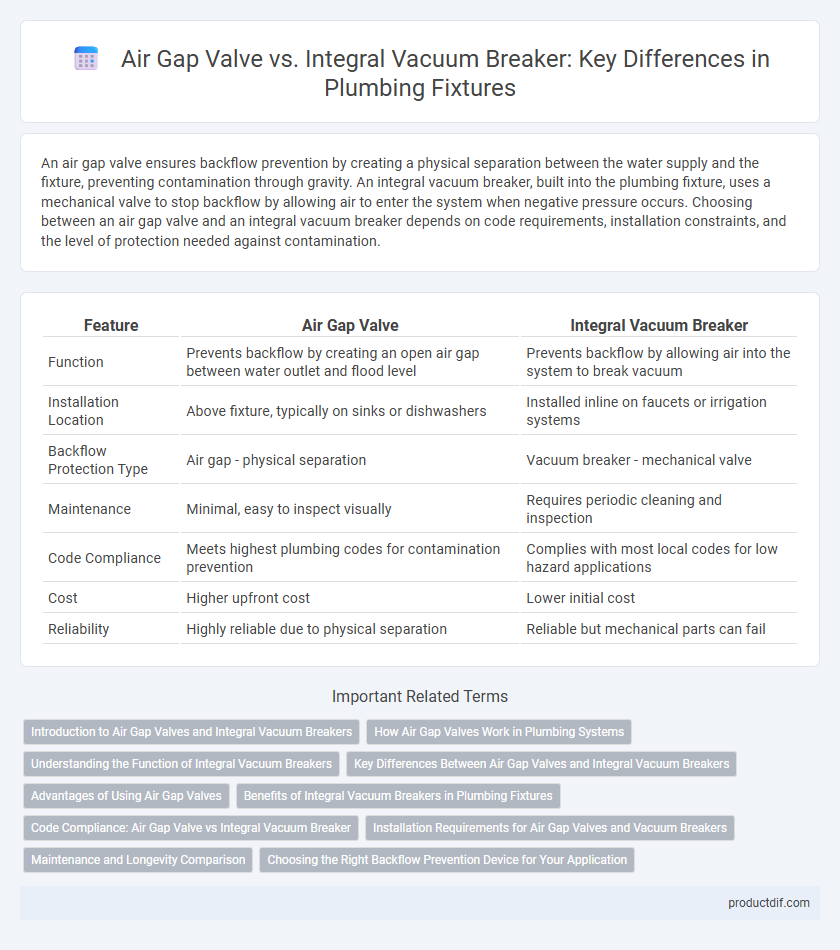

An air gap valve ensures backflow prevention by creating a physical separation between the water supply and the fixture, preventing contamination through gravity. An integral vacuum breaker, built into the plumbing fixture, uses a mechanical valve to stop backflow by allowing air to enter the system when negative pressure occurs. Choosing between an air gap valve and an integral vacuum breaker depends on code requirements, installation constraints, and the level of protection needed against contamination.

Table of Comparison

| Feature | Air Gap Valve | Integral Vacuum Breaker |

|---|---|---|

| Function | Prevents backflow by creating an open air gap between water outlet and flood level | Prevents backflow by allowing air into the system to break vacuum |

| Installation Location | Above fixture, typically on sinks or dishwashers | Installed inline on faucets or irrigation systems |

| Backflow Protection Type | Air gap - physical separation | Vacuum breaker - mechanical valve |

| Maintenance | Minimal, easy to inspect visually | Requires periodic cleaning and inspection |

| Code Compliance | Meets highest plumbing codes for contamination prevention | Complies with most local codes for low hazard applications |

| Cost | Higher upfront cost | Lower initial cost |

| Reliability | Highly reliable due to physical separation | Reliable but mechanical parts can fail |

Introduction to Air Gap Valves and Integral Vacuum Breakers

Air gap valves create a physical separation between the water outlet and the flood level to prevent backflow contamination in plumbing systems. Integral vacuum breakers are devices installed directly on faucets or hose bibbs to automatically prevent back siphonage by allowing air into the system when negative pressure occurs. Both components are critical for maintaining potable water safety and complying with plumbing codes in residential and commercial installations.

How Air Gap Valves Work in Plumbing Systems

Air gap valves function by creating a physical separation between the water outlet and the flood level of the fixture, preventing backflow contamination in plumbing systems. This gap allows contaminated water to drain away without re-entering the clean water supply, ensuring compliance with health codes. Unlike integral vacuum breakers, air gap valves rely on an open space rather than mechanical components to maintain a non-reversible flow and protect potable water.

Understanding the Function of Integral Vacuum Breakers

Integral vacuum breakers are essential plumbing fixtures designed to prevent backflow by allowing air into the water system when negative pressure occurs, effectively breaking the vacuum and protecting potable water supplies. Unlike air gap valves, which create a physical separation between the water outlet and flood level, integral vacuum breakers are installed directly on the fixture or pipe, providing a compact and automatic solution to back-siphonage. Their reliable function ensures compliance with plumbing codes while maintaining continuous water flow without interruption.

Key Differences Between Air Gap Valves and Integral Vacuum Breakers

Air gap valves ensure backflow prevention by providing a physical separation between the water outlet and the flood level, while integral vacuum breakers prevent back siphonage by allowing air into the system to break suction. Air gap valves are typically installed in sink drains adhering to codes requiring visible separation, whereas integral vacuum breakers are often found on outdoor hose bibbs and irrigation systems. The main functional difference is that air gaps rely on gravity and physical space, while vacuum breakers depend on mechanical components to maintain safe water flow.

Advantages of Using Air Gap Valves

Air gap valves provide superior protection against backflow contamination by maintaining a physical separation between the water supply and potential contaminants, ensuring compliance with plumbing codes. They require minimal maintenance compared to integral vacuum breakers, which have moving parts prone to wear and failure over time. Their simple design allows for reliable, long-lasting performance in both residential and commercial plumbing fixtures.

Benefits of Integral Vacuum Breakers in Plumbing Fixtures

Integral vacuum breakers prevent backflow by allowing air to enter the plumbing system, thus safeguarding potable water supplies from contamination. They are compact, cost-effective, and easy to install, requiring minimal maintenance compared to separate air gap valves. Integral vacuum breakers ensure reliable protection in irrigation systems, outdoor faucets, and hose bibbs, enhancing overall plumbing fixture performance and code compliance.

Code Compliance: Air Gap Valve vs Integral Vacuum Breaker

Air gap valves meet plumbing code requirements by providing a physical separation between the water supply and drain, preventing backflow contamination. Integral vacuum breakers comply with many plumbing codes by allowing air intrusion to break siphonage but may not be accepted in all jurisdictions for high-hazard systems. Selecting between an air gap valve and an integral vacuum breaker depends on specific local plumbing codes and risk assessments associated with cross-connection control.

Installation Requirements for Air Gap Valves and Vacuum Breakers

Air gap valves require a minimum vertical clearance above the flood level rim of the fixture to prevent backflow contamination, typically a distance of at least twice the pipe diameter. Integral vacuum breakers must be installed at a higher elevation than the highest water outlet to ensure effective prevention of back-siphonage. Proper placement and adherence to local plumbing codes are critical for both devices to maintain compliance and ensure reliable backflow protection.

Maintenance and Longevity Comparison

Air gap valves require minimal maintenance, as their simple design prevents debris buildup and reduces clogging risks, leading to extended operational life. Integral vacuum breakers contain moving parts that may need periodic inspection and cleaning to ensure proper function and prevent failure, potentially shortening lifespan if neglected. Overall, air gap valves offer greater durability and lower upkeep demands compared to integral vacuum breakers in plumbing systems.

Choosing the Right Backflow Prevention Device for Your Application

Selecting the appropriate backflow prevention device depends on the specific plumbing application and local code requirements. An air gap valve provides a physical separation between the water supply and potential contaminants, ensuring maximum protection in situations with high risk of backflow. Integral vacuum breakers are suitable for lower-risk fixtures, offering a compact solution that prevents back-siphonage without requiring additional installation space.

air gap valve vs integral vacuum breaker Infographic

productdif.com

productdif.com